Thickness setting device of continuous foaming material

A technology of foaming materials and foaming chambers, which is applied in thin material processing, coiling strips, transportation and packaging, etc., and can solve problems such as affecting bonding, slow cooling speed, and excessive sheet extrusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

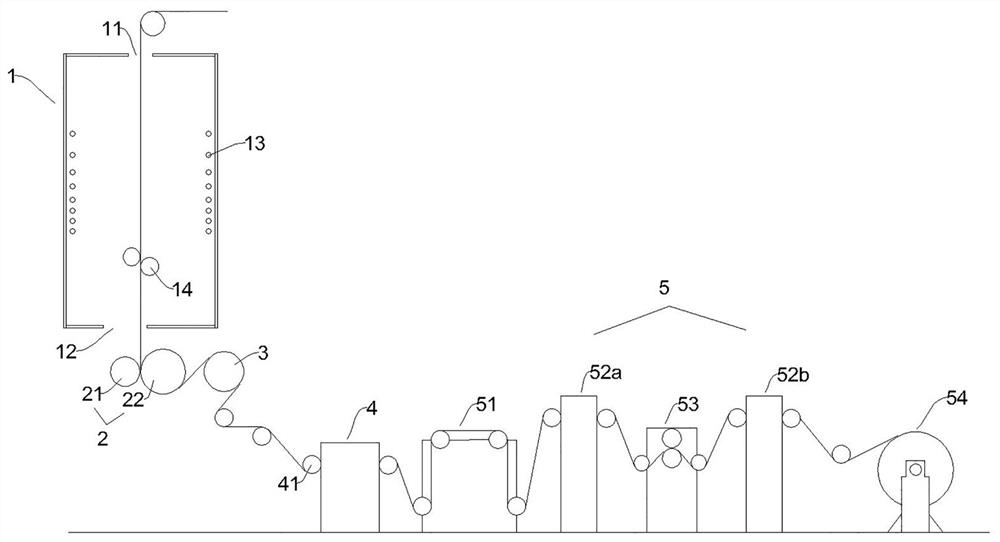

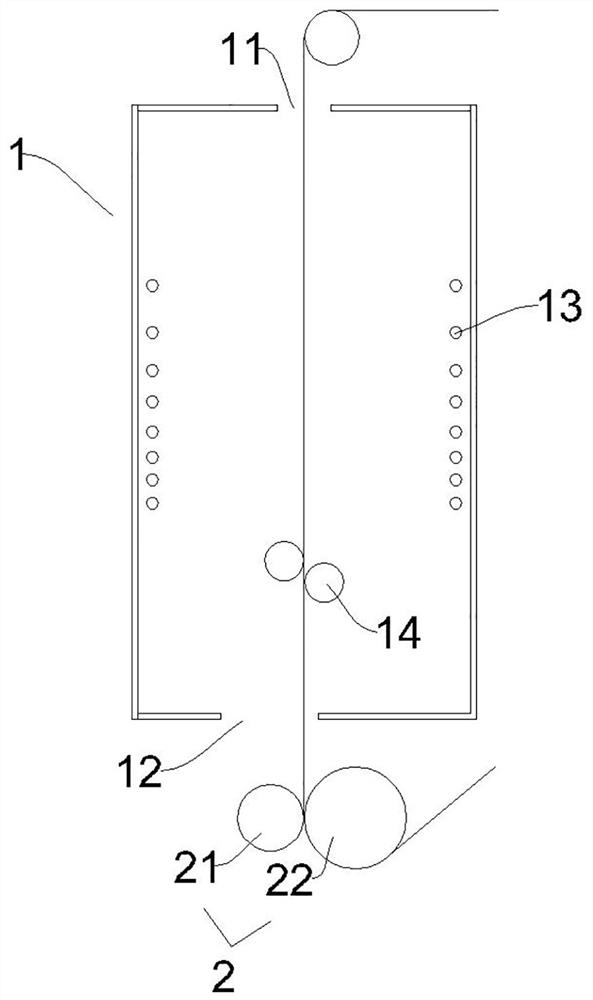

[0038] A thickness setting device for continuous foaming materials, such as figure 1 As shown, it includes a foaming chamber 1 and a thickened part 2; in this embodiment, the foaming chamber 1 is a vertical foaming chamber, and the upper and lower ends are respectively provided with a feed port 11 and a discharge port 12, and the foaming chamber The inner wall of 1 is provided with several heating elements 13 along the conveying direction of the foaming material, and the heating elements 13 are arranged in the middle of the inner wall of the foaming furnace 1, and an unfolding roller 14 is arranged under the area where the heating elements 13 are arranged, and the inside of the unfolding roller 14 is Hollow, and equipped with cooling water inlet.

[0039] The thickening part 2 is arranged on the outside of the discharge port 12, such as Figure 1-2 As shown, it includes a pressure roller 21 and a turning roller 22 that are provided with a cooling structure 23 on the opposite ...

Embodiment 2

[0042] A production equipment for continuous foaming materials, the basic structure of which is the same as that of Embodiment 1, the difference is that in this embodiment only a cooling structure 23 is provided on the surface of the pressure roller 21 .

Embodiment 3

[0044] A continuous foaming material production equipment, the basic structure is the same as embodiment 1, the difference is: the foaming chamber 1 of this embodiment is a horizontal foaming chamber, such as image 3 As shown, the left and right ends of the foaming chamber 1 are respectively provided with a material inlet 11 and a material outlet 12, and the embossing roller 21 and the turning roller 22 are arranged opposite to each other up and down, and the rest of the structure is the same as that of Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com