Processing technology of welded nut

A welding nut and processing technology, which is applied to nuts, connecting components, threaded fasteners, etc., can solve the problems of large deviation of the verticality of threaded holes, inconsistent height of welding points, deviation of welding point size, etc., and achieves good processing quality, High pass rate and highly consistent results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Embodiments of the present invention will be further described below in conjunction with accompanying drawings:

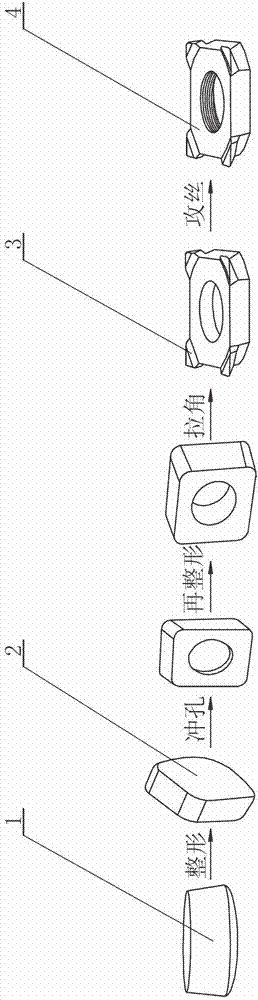

[0015] Such as figure 1 Shown, a kind of processing technology of welding nut, this technology is as follows:

[0016] a. The nut body 2 is shaped, and the blank 1 is cold-headed with a cold heading machine, and the cold heading is continued for 2 to 3 times, so that the corners of the nut body 2 are full and consistent;

[0017] b. Punching, using a cold heading machine to punch out a through hole at the center of the nut body 2;

[0018] c. The nut body 2 is reshaped, and the center hole of the nut body 2 is used as the positioning reference, and the nut body 2 is reshaped with a cold heading machine, so that the corners of the nut body 2 are full and consistent;

[0019] d. Draw angle, take the center hole of the nut body 2 as the positioning reference, and use a cold heading machine to upset a plurality of welding points 3 with the same height at the e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com