Vertical stone grinding equipment

A stone and equipment technology, applied in the field of vertical stone grinding equipment, can solve the problems of different weights at both ends of the railing, one-sided force on the clamping workbench, and influence on service life, etc., to achieve small footprint, stable force, The effect of high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

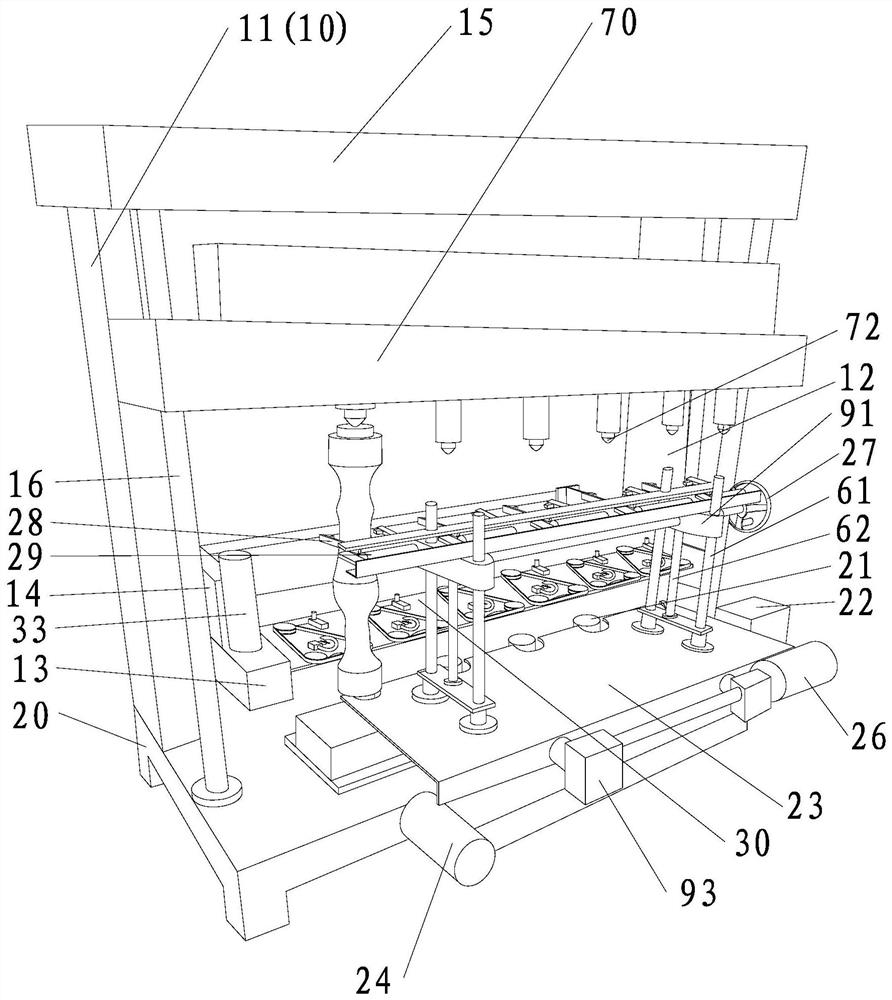

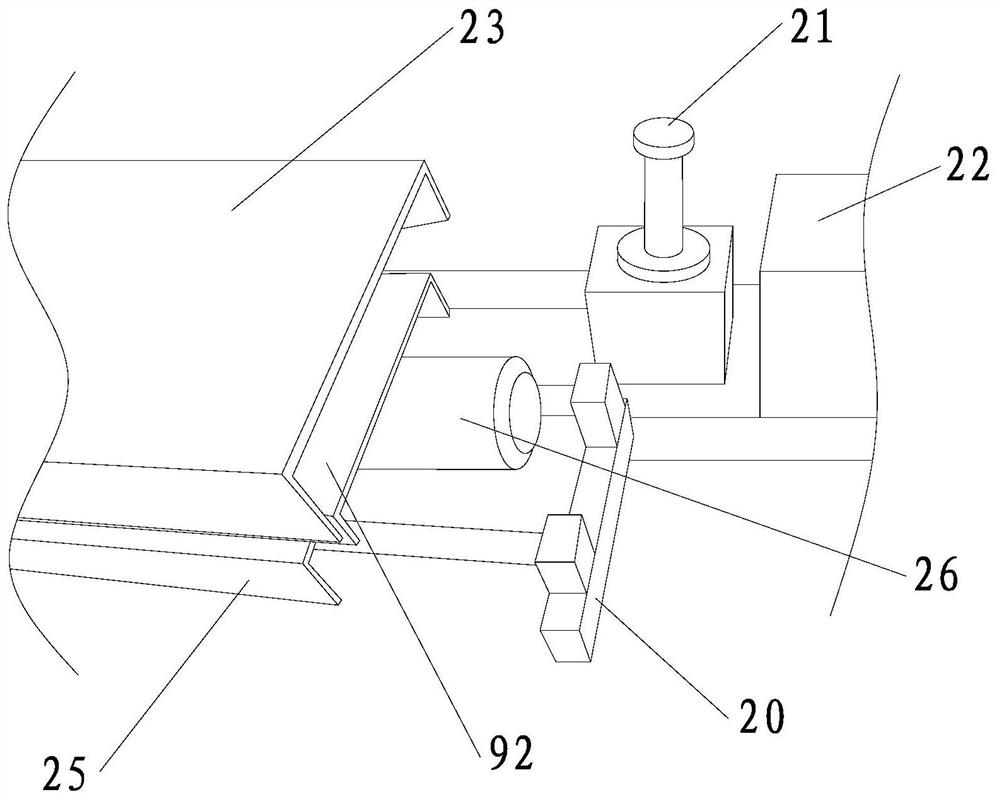

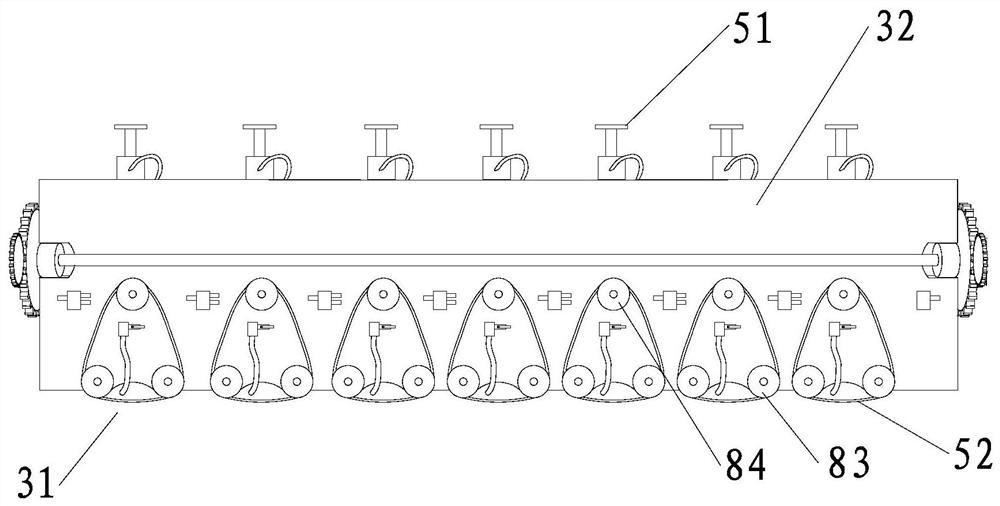

[0053] like Figure 1-Figure 4 As shown, the vertical stone grinding equipment provided in this embodiment is mainly used for grinding strip-shaped stone such as railings and stone pillars. The rack 10 has vertically arranged first uprights 11 and second uprights 12. The number of the first uprights 11 and the second uprights 12 can be determined according to actual needs. In this embodiment, the first uprights 11 and the second uprights 12 are each There is an example to illustrate, a top beam 15 is connected between the top of the first column 11 and the top of the second column 12 to improve the stability of the rack 10 . The upright column 11 and the second upright column 12 are respectively connected with a lift seat 13 in a vertical sliding manner. It should be noted that when there are multiple first upright columns 11 or second upright columns 12, the corresponding lift seats 13 are vertically slidably connected to each of them at the same time. There are only two lif...

Embodiment 2

[0067] like Image 6 As shown, the difference between this embodiment and the first embodiment is that the structure of the clamping jaws 28 is different. Specifically, in this embodiment, the clamping jaws 28 include first sliders that are respectively horizontally slidably connected to the clamping frame 91 . 67 and the second sliding block 68, the first clamping rod 65 fixedly connected with the first sliding block 67, the second clamping rod 66 fixedly connected with the second sliding block 68, and the middle part of the rod body is rotatably connected to the clamping frame 91 and the first link 94 and the second link 95 rotatably connected to both ends of the intermediate link 69, wherein the end of the first link 94 away from the intermediate link 69 rotates with the first clamping rod 65 For connection, one end of the second link 95 away from the intermediate link 69 is rotatably connected with the second link 95 . The number of clamping jaw driving devices 29 is the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com