Manufacturing method of aluminum-silicon coated steel/high-strength hot-formed steel composite steel part

A hot forming steel and manufacturing method technology, applied in the field of auto parts manufacturing, can solve the problems of increased welding difficulty, unstable production, short residence time of welding pool, etc., to enhance strength and toughness, improve strength and Toughness, the effect of improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

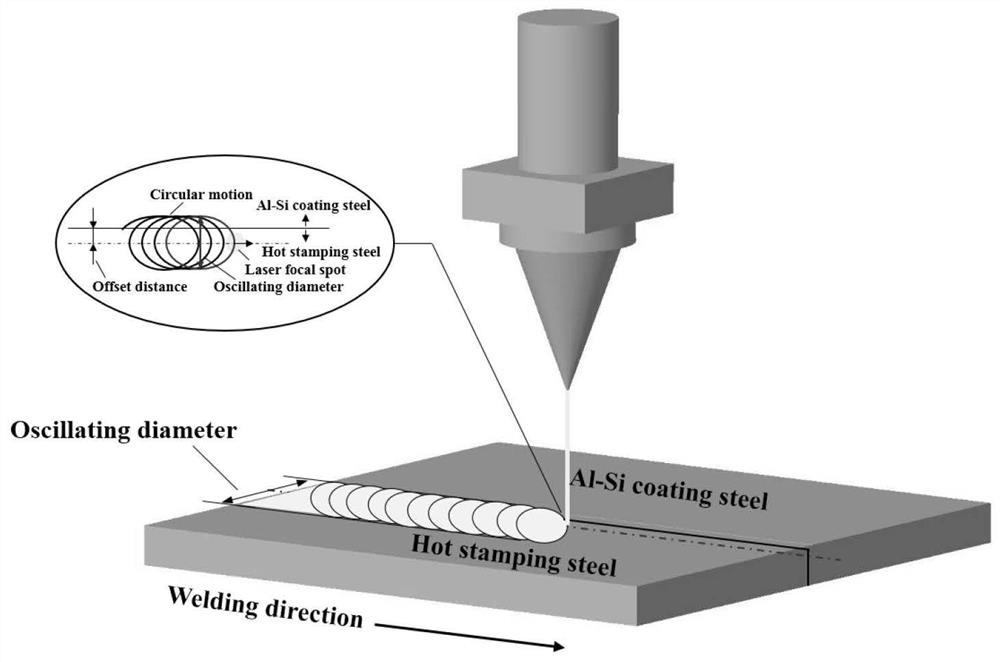

[0062] The oscillating vibrating mirror welding method of aluminum-silicon coated steel / high-strength hot-formed steel comprises the following steps:

[0063] Step (1): Select 1.5mm thick aluminum-silicon coated 22MnB5 steel and 1.5mm thick 2GPa hot-formed steel, and use alcohol to degrease; the thickness of the aluminum-silicon coated 22MnB5 steel is 20 μm to 40 μm.

[0064] Step (2): Place the two steel plates on the workbench in the form of splicing, and use a special welding fixture to make the two steel plates closely contact.

[0065] Step (3): Use the IPG-6kW fiber laser to weld the test plate. The laser power used is 3.0kW, the welding speed is 5.0m / min, the swing diameter is 0.5mm, the swing frequency is 50Hz, and the defocus amount is +5.0mm, the protective gas used is 80% Ar+20% CO 2 , the spot path is shifted by 0.5mm from the two-plate splicing path to the 2GPa hot-formed steel side during welding.

[0066] Step (4): After the tailor-welded blank is obtained, it...

Embodiment 2

[0069] Oscillating laser welding of aluminum-silicon-coated steel / high-strength hot-formed steel includes the following steps:

[0070] Step (1): Select 22MnB5 steel with 2.0mm thick aluminum-silicon coating and 1.5mm thick 1800MPa hot-formed steel, and degrease with alcohol; the coating thickness of the 22MnB5 steel with aluminum-silicon coating is 20 μm to 40 μm.

[0071] Step (2): Place the two steel plates on the workbench in the form of splicing, and use a special welding fixture to make the two steel plates closely contact.

[0072] Step (3): Use the IPG-10kW fiber laser to weld the test plate. The laser power used is 10.0kW, the welding speed is 6.0m / min, the defocus is 0mm, the swing diameter is 6.0mm, and the spot direction is 1800MPa The steel side is offset by 2.5mm and the oscillation frequency is 50Hz. The protective gas used is 100% CO 2 , the moving path of the spot during welding is the splicing path of two steel plates.

[0073] Step (4): After the tailor-w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com