Powder metallurgy diffusion method for preparing foamed aluminum, foamed aluminum and sandwich foamed aluminum plate prepared by same

A technology of powder metallurgy and diffusion method, used in other manufacturing equipment/tools, turbines, engine components, etc., can solve the problems of decreased quality of foam materials, increased defects, unfavorable foaming process, etc., to eliminate cracks and holes, high quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

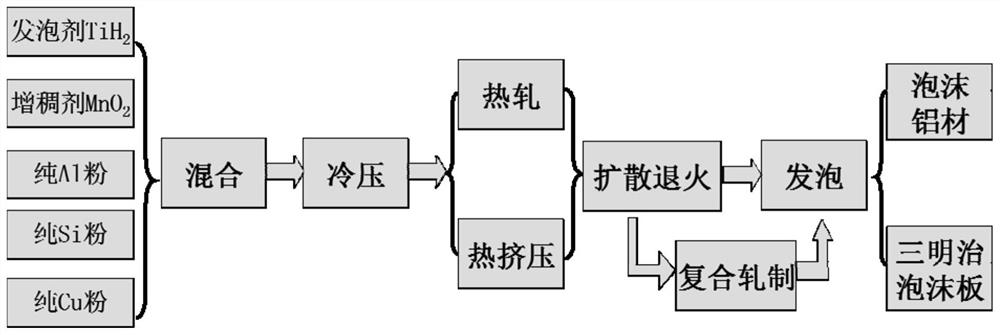

[0024] according to figure 1 The process flow chart for preparing foamed aluminum is used to prepare foamed aluminum, wherein hot rolling is used after cold pressing.

[0025] The raw material is the blowing agent TiH 2 (300 mesh) 0.8 parts by weight, thickener MnO 2 (300 mesh) 1.2 weight parts, pure Al powder (300 mesh) 87 weight parts, pure Si powder (400 mesh) 6 weight parts and pure Cu powder (300 mesh) 5 weight parts, above raw material powder all is market purchase, purity Higher than 99%.

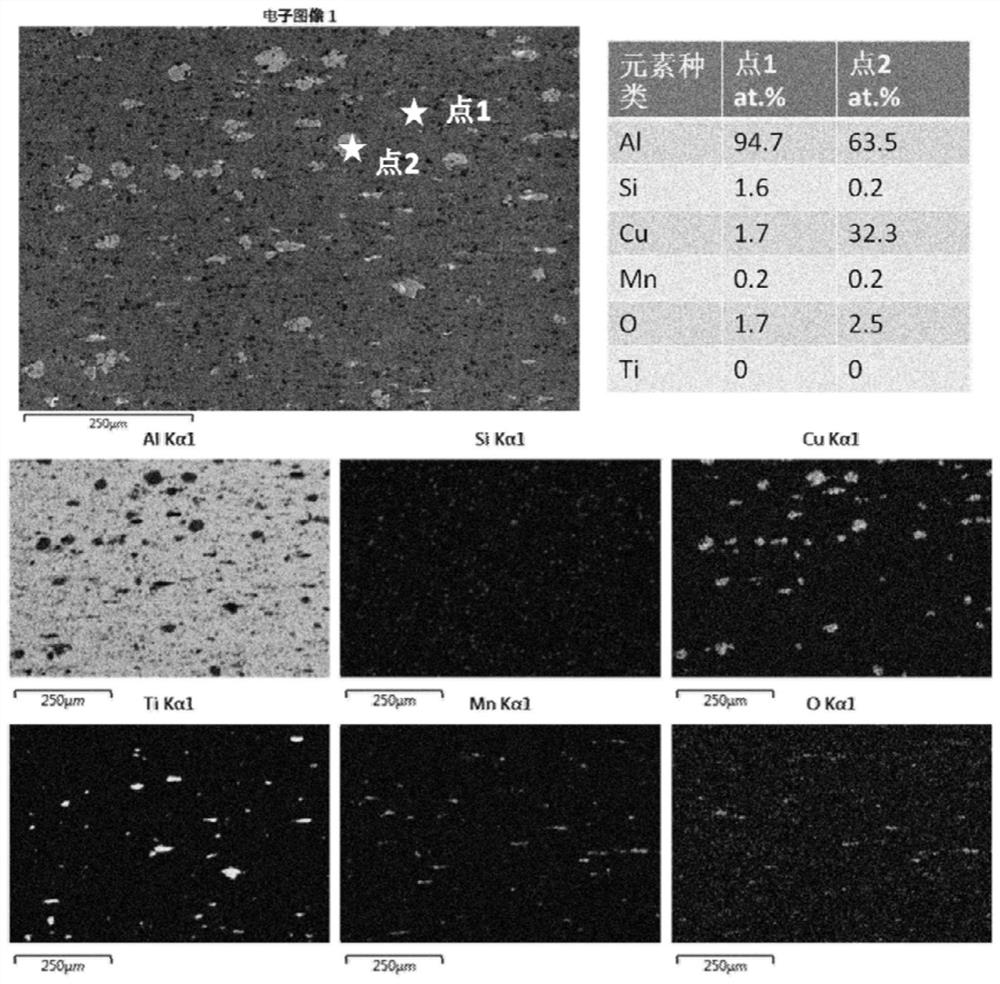

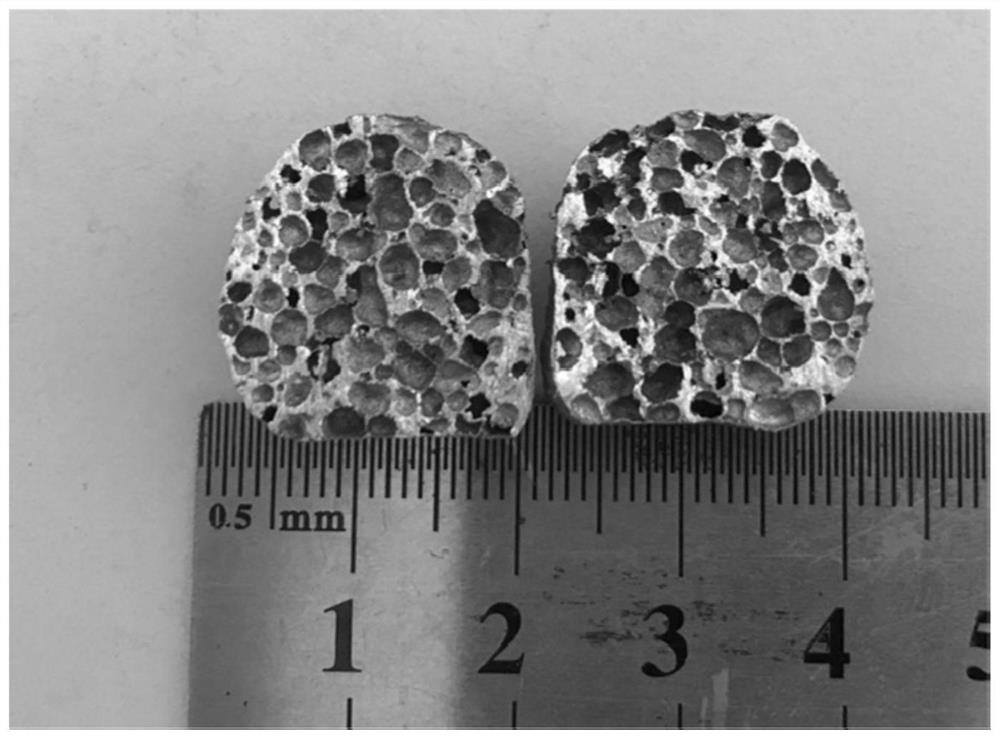

[0026] The powder mixing process adopts ball milling for 30 minutes, and the cold pressing pressure is 400MPa. After cold pressing, the foaming precursor body is preheated at 475°C for 30 minutes, and then hot rolled. The initial thickness of hot rolling is 15.1±0.1mm, and the final thickness is 2.8± 0.1mm. A diffusion annealing step is performed, the diffusion annealing temperature is 475° C., and the annealing time is 48 h. The temperature of the foaming process is 640° C., an...

Embodiment 2

[0030] Carry out in substantially the same manner as in Example 1, except that the raw material is blowing agent TiH 2 (300 mesh) 0.6 parts by weight, thickener MnO 2 (300 mesh) 0.6 weight part, pure Al powder (300 mesh) 88.8 weight part, pure Si powder (400 mesh) 8 weight part and pure Cu powder (300 mesh) 2 weight part, above raw material powder all is market purchase, purity Higher than 99%.

[0031] The foaming precursor prepared in Example 2 has no defects such as cracks and holes, and the final foamed aluminum material is relatively uniform in pore size, with a foaming porosity of 65%, a pore size of 0.6-1.4 mm, and no large through holes, Pore structure defects such as cracks.

Embodiment 3

[0033] Carry out in substantially the same manner as Example 1, the difference is that wherein the raw material is blowing agent TiH 2 (300 mesh) 1.4 parts by weight, thickener MnO2 (300 orders) 1.8 parts by weight, pure Al powder (300 orders) 85.8 parts by weight, pure Si powder (400 orders) 4 parts by weight and pure Cu powder (300 orders) 7 parts by weight, above raw material powders all are market purchases, purity Higher than 99%.

[0034] The foaming precursor prepared in Example 3 has no defects such as cracks and holes, and the final foamed aluminum material is relatively uniform in pore size, with a foaming porosity of 82%, a pore size of 0.9-2.0mm, and no large through holes, Pore structure defects such as cracks.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com