Method and device for removing chlorine-containing organic pollutants in flue gas through combination of ozone catalysis and wet process

A technology of organic pollutants and ozone catalysis, applied in chemical instruments and methods, separation methods, gas treatment, etc., can solve the problem of underreporting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

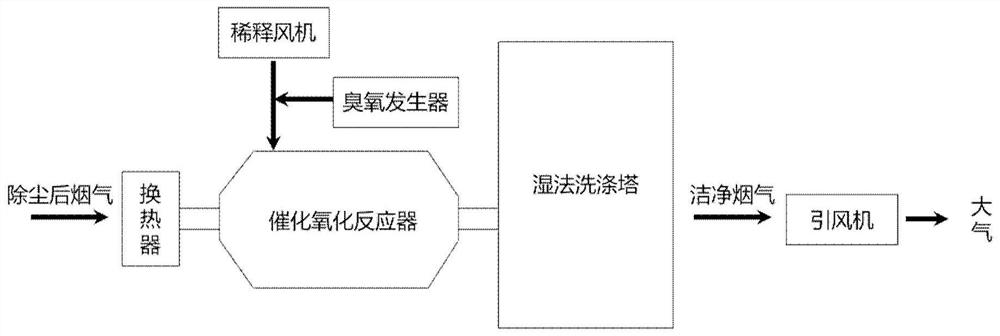

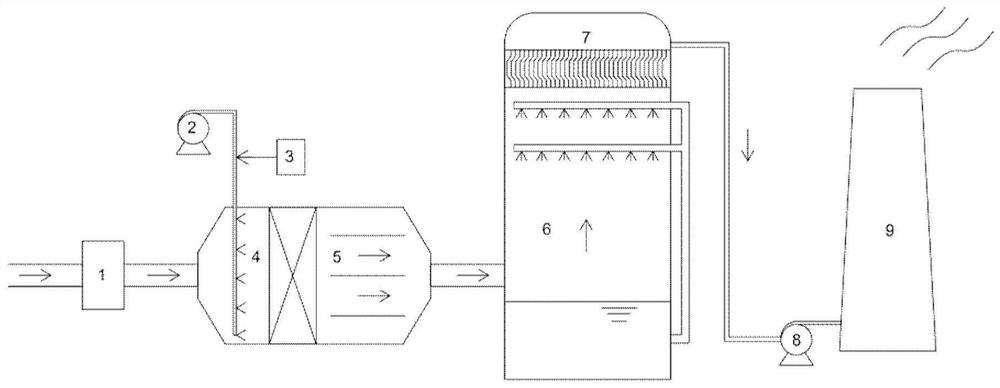

[0079] Embodiment 1 is the method and device (combining figure 1 , figure 2 illustrate).

[0080] The method is as follows: before entering the catalytic oxidation reactor 4, the incoming flue gas with chlorine-containing organic pollutants passes through the heat exchanger 1 to control the temperature of the flue gas at 60-130 °C, and the ozone generated by the ozone generator 3 is diluted by the fan. 2 After dilution, it is sprayed into the catalytic oxidation reactor 4 to participate in the reaction. The molar ratio of the amount of ozone added to the concentration of chlorine-containing organic pollutants in the flue gas is 2 to 15 (the specific ratio should be selected according to the type of chlorine-containing organic pollutants and the initial concentration. and target emission concentration), control the catalytic oxidation reaction time for at least 0.2 seconds, and the chlorine-containing organic pollutants in the flue gas are oxidized to HCl, Cl 2 , CO 2 and H...

Embodiment 2

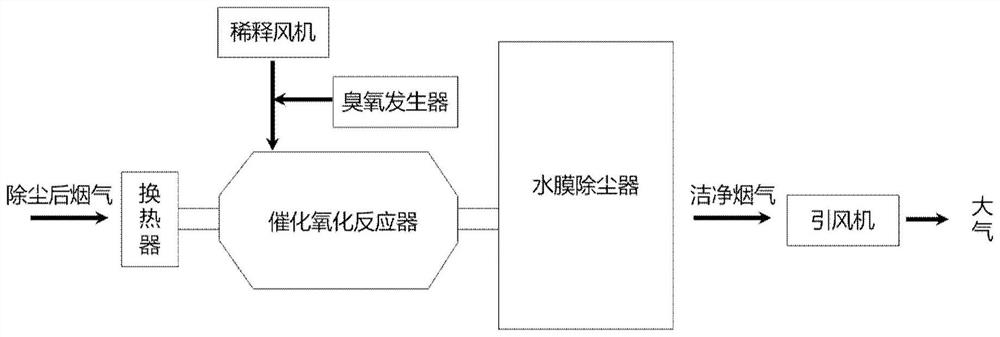

[0082] Embodiment 2 is the method and device (combining image 3 , Figure 4 illustrate).

[0083] The method is as follows, the incoming flue gas with chlorine-containing organic pollutants and relatively large smoke content enters the water film dust collector 10 after passing through the catalytic oxidation reactor 4 . In the water film dust collector 10, HCl, Cl 2 And the particles will be quickly and efficiently removed by the droplets in the tower space, so as to realize the removal of chlorine-containing organic pollutants and particles. Other steps are identical with embodiment 1.

Embodiment 3

[0085] Embodiment 3 is ozone low temperature synergistic oxidation NO x Method and device for combined wet absorption with chlorinated organic pollutants (combined figure 1 , figure 2 illustrate).

[0086] The method is as follows, with NO x And the incoming flue gas containing chlorine organic pollutants enters the catalytic oxidation reactor 4 and then enters the wet scrubber 6 . due to NO x The concentration is significantly higher than the concentration of chlorine-containing organic pollutants. The molar ratio of ozone dosage and NO concentration in the flue gas is dynamically adjusted from 0.5 to 1.5. The residual ozone can complete the oxidation of low-concentration chlorine-containing organic pollutants in the flue gas. In the catalytic oxidation reaction, NO in flue gas is oxidized to high-valence nitrogen oxides (NO 2 , N 2 o 5 ), the chlorine-containing organic pollutants in the flue gas are oxidized to HCl, Cl 2 , CO 2 and H 2 O. In addition, SO in flue...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com