Electrode dirt detection method

A detection method and electrode technology, which are applied in image data processing, instrument, character and pattern recognition, etc., can solve the problems of large workload of manual parameter adjustment, large calculation amount of detection method, low detection accuracy, etc., and reduce manual parameter adjustment. workload, the effect of eliminating the effects of uneven lighting, and reducing computing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

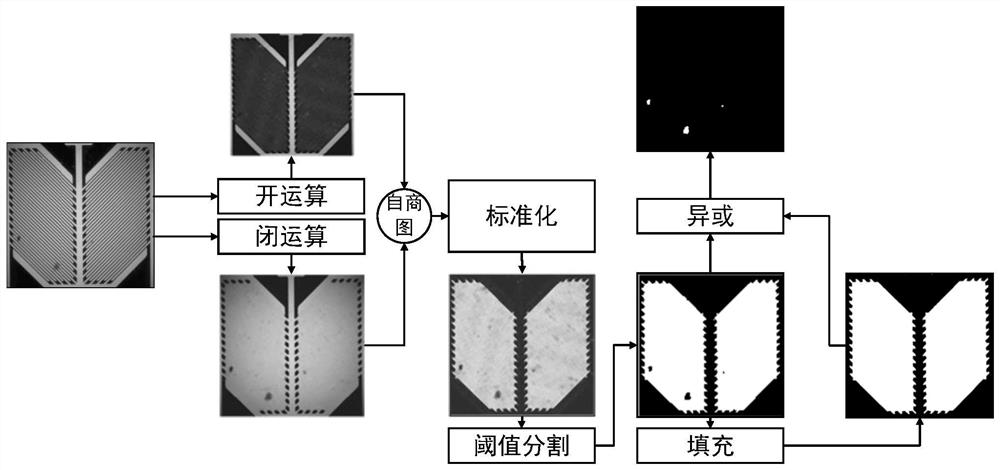

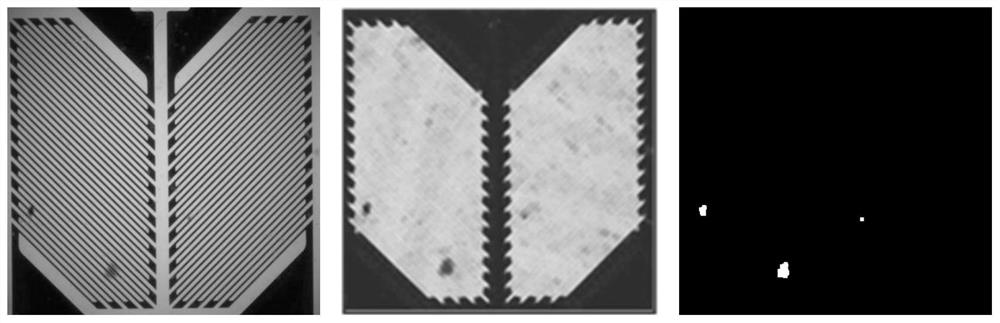

[0032] Electrode contamination detection methods include:

[0033] Step 1: Preprocessing the electrode image obtained by the camera to obtain the grayscale image of the electrode.

[0034] Preprocess the image. If the image is a color image, according to experience, the general electrode part color is FPC yellow, metal silver, and the background is generally black or circuit board green, red, yellow, blue. Therefore, when encountering a color image, use the dark channel prior method to take the minimum value for the corresponding position components of the three channels to obtain an image I with stronger contrast:

[0035] I(x,y)=min(R(x,y),G(x,y),B(x,y))

[0036] Among them, I(x, y) is the value of the electrode grayscale image I at the position (x, y), R(x, y), G(x, y), B(x, y) represent the position (x, y) respectively , red, green and blue channel component values of the pixel at y)

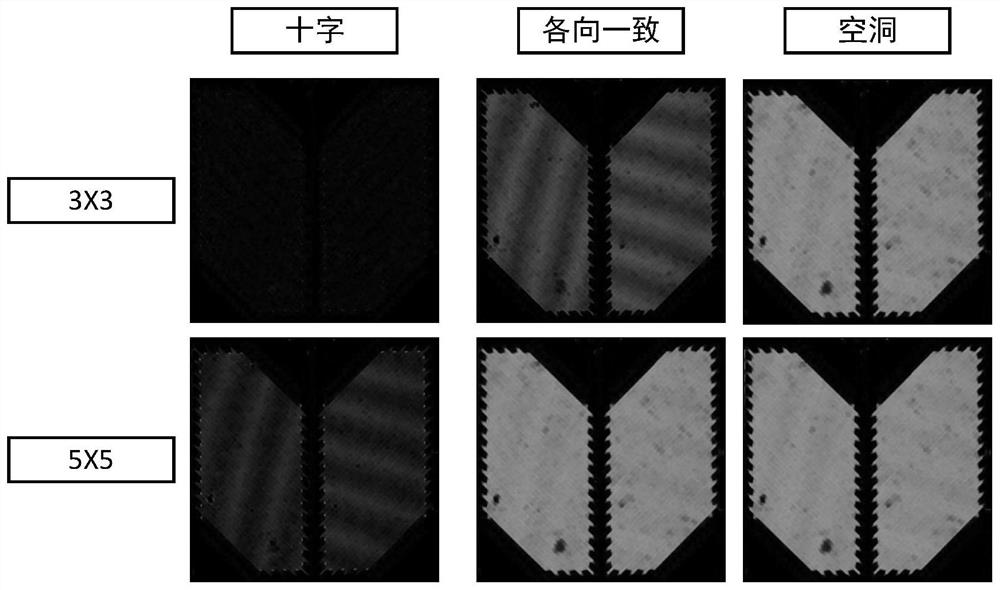

[0037] Step 2: Construct a morphological operator template set, and perform opening...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com