Tunnel supporting structure

A technology for supporting structures and tunnels, which is applied in tunnels, tunnel linings, shaft linings, etc., and can solve problems such as tunnel safety threats, karst columns/collapsed columns are easy to collapse again, and grouting bodies are not firm.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

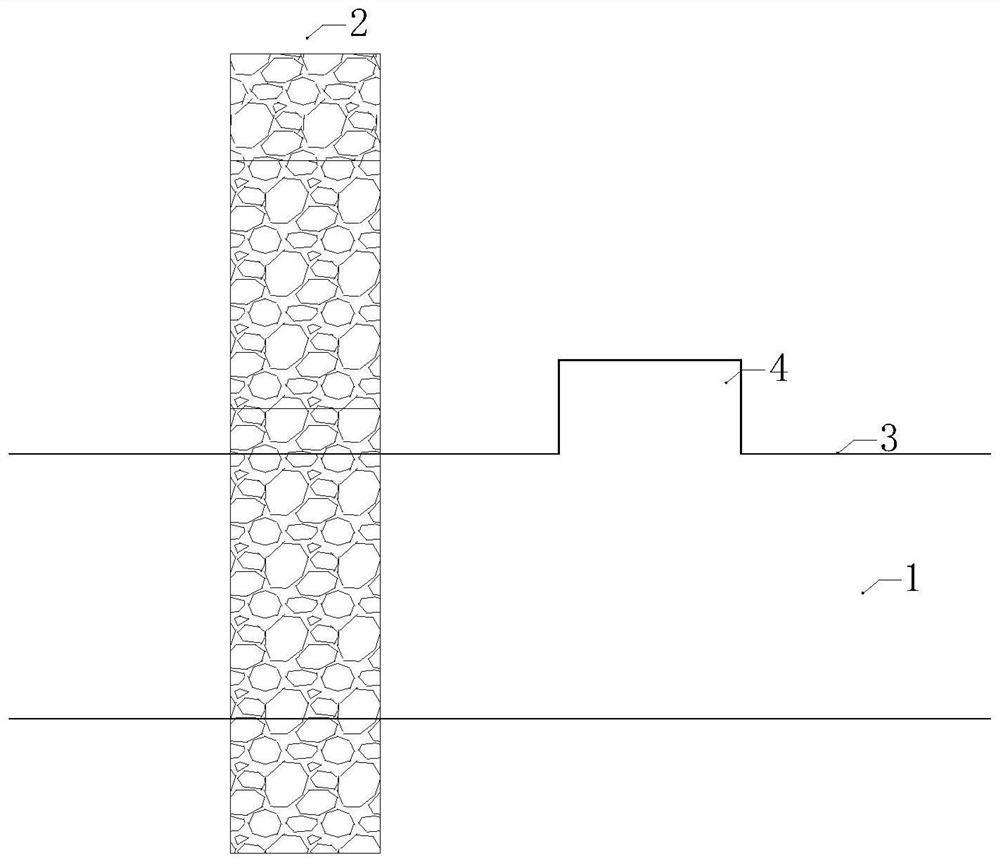

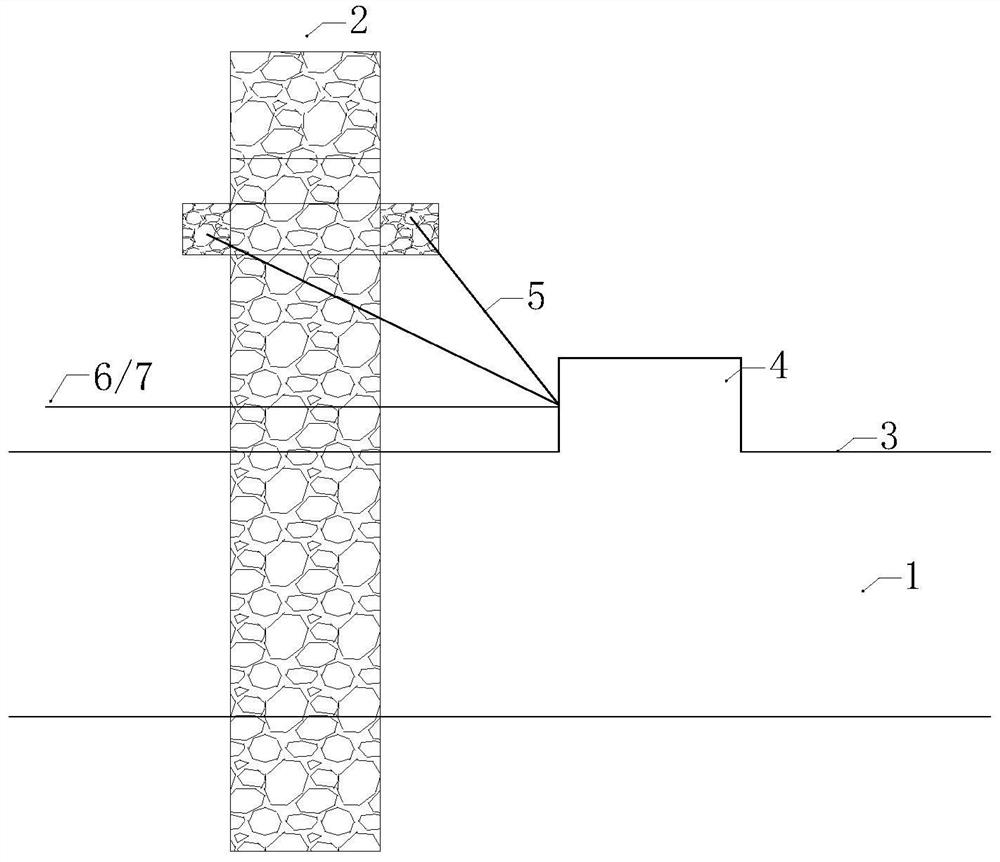

[0032] The present invention will be further described in detail below in conjunction with the drawings.

[0033] Such as Figure 1-4 , A tunnel support structure, including tunnel 1, a collapse column that intersects with tunnel 1 and is perpendicular to tunnel 1, a distance from the collapse column and a construction chamber 4 formed by expanding the tunnel roof 3, and blasting a certain height above the tunnel The annular artificial blasting area 14 formed by the complete rock mass around the collapse column at the position, the shape of the collapse column after blasting is nail-shaped;

[0034] It also includes the pipe roof pipe 7 which passes through the collapsed column from the construction chamber and enters the stable rock mass in front for a certain distance. The pipe roof pipe includes grouting steel pipes and ordinary steel pipes. Grout reinforcement, ordinary steel pipes can be solid or high-strength hollow steel pipes, which can not only improve the overall strength...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com