Plating solution formula and process for vertical high-speed continuous tin plating

A high-speed plating, vertical technology, applied in the direction of plating tanks, electrodes, etc., can solve the problems of wire scratches, tin layer eccentricity, current density plating solution can not work normally, effectively and stably, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

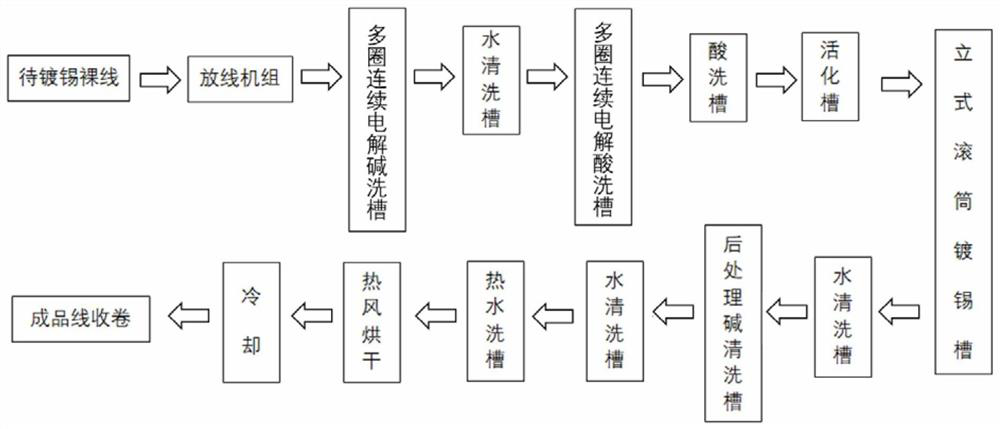

Method used

Image

Examples

Embodiment 1

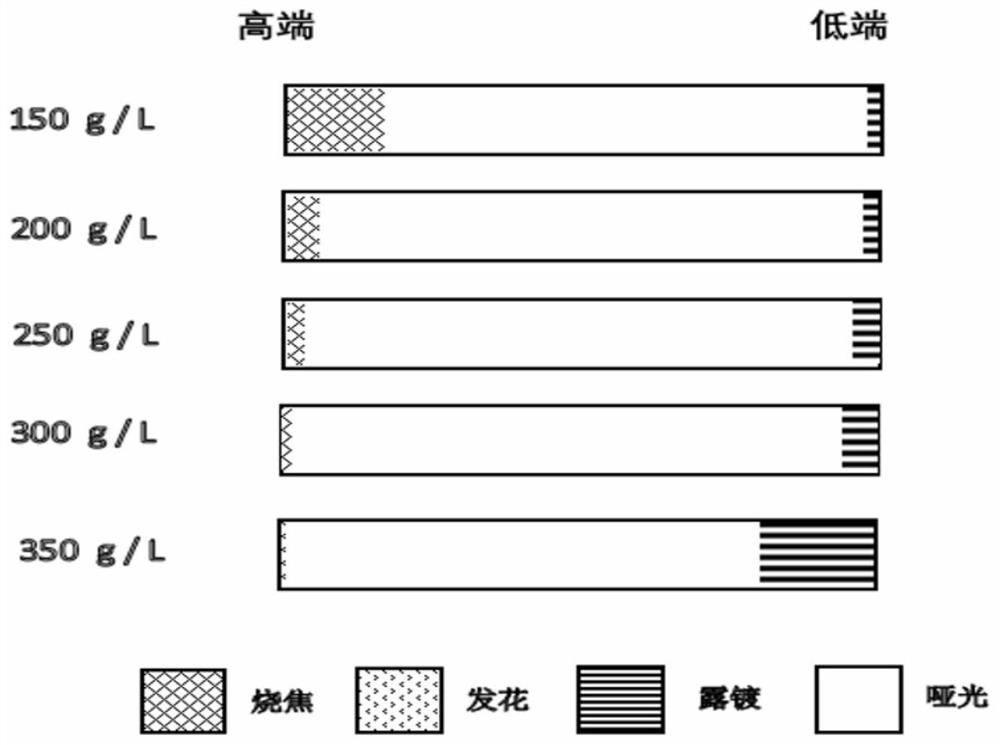

[0051] The present embodiment relates to a kind of plating bath prescription of vertical high-speed tin plating, comprises each component of mass-volume concentration as follows: tin protosulfonate (sn 2+ ) 65g / L, combined additives 60g / L, phenolsulfonic acid 150g / L, 200g / L, 250g / L, 300g / L, 350g / L respectively.

[0052] The composition of described combination additive is: dispersant (polyethylene glycol) 2ml / L, anti-scorch agent 0.5ml / L, grain refiner (2-naphthol and others) 40mg / L, antioxidant: 0.2 g / L, flocculant: 0.1g / L, other auxiliary agents 1.0ml / L.

[0053] The dispersant is polyethylene glycol; the grain refiner is 2-naphthol; the antioxidant is sodium hypophosphite; the flocculant is polyacrylamide; Phenylenediamine or m-phenylenediamine; the other auxiliary agent can be, for example, an impurity-removing additive, and the impurity-removing additive is preferably ethylenediaminetetraacetic acid.

[0054] With the above plating solution formula, the tin plating oper...

Embodiment 2

[0059] The present embodiment relates to a kind of plating bath prescription of vertical high-speed tin plating, comprises each component of mass-volume concentration as follows: phenol sulfonic acid 250g / L, combined additive 60g / L, tin protophenol sulfonate (sn 2+ ) respectively take 20g / L, 40g / L, 60g / L, 80g / L, 100g / L.

[0060] The composition of described combination additive is: dispersant (polyethylene glycol) 2ml / L, anti-scorch agent 0.5ml / L, grain refiner (2-naphthol and others) 40mg / L, antioxidant: 0.2 g / L, flocculant: 0.1g / L, other auxiliary agents 1.0ml / L.

[0061] With the above plating solution formula, the tin plating operation is carried out under the conditions of temperature 50°C, stirring speed 200rpm, I=5A, and time 1min. The results of Hull Cell test pieces under different phenolsulfonic acid concentrations are as follows image 3 shown. Experiments have shown that increasing the Sn 2+ The concentration can broaden the range of current density, but Sn 2+ ...

Embodiment 3

[0063] The present embodiment relates to a kind of plating bath prescription of vertical high-speed tin plating, comprises each component of mass-volume concentration as follows: phenolsulfonic acid 250g / L, phenolsulfonic acid stannous (sn 2+ ) 75g / L, the combined additives are 40g / L, 60g / L and 80g / L respectively.

[0064] The composition of described combination additive is: dispersant (polyethylene glycol) 2ml / L, anti-scorch agent 0.5ml / L, grain refiner (2-naphthol and others) 40mg / L, antioxidant: 0.2 g / L, flocculant: 0.1g / L, other auxiliary agents 1.0ml / L.

[0065] With above-mentioned bath formula, carry out tinning operation under the condition of temperature 50 ℃, stirring speed 200rpm, I=5A, time 1min, the Hull Cell test piece result test piece under different phenolsulfonic acid concentration all agrees with image 3 The test piece is equivalent under the condition of 60g / L stannous phenolsulfonate.

[0066] Hull Cell shows that under the condition of high-speed tin ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com