Polyamide composition and preparation method thereof

A polyamide composition and polyamide technology, which are applied in the field of polymer materials, can solve the problems of large shrinkage, reduced mechanical properties, electrical properties and other properties, and the degree of improvement is not obvious, and achieve excellent mechanical properties and improved dimensional stability. , the effect of reducing water absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

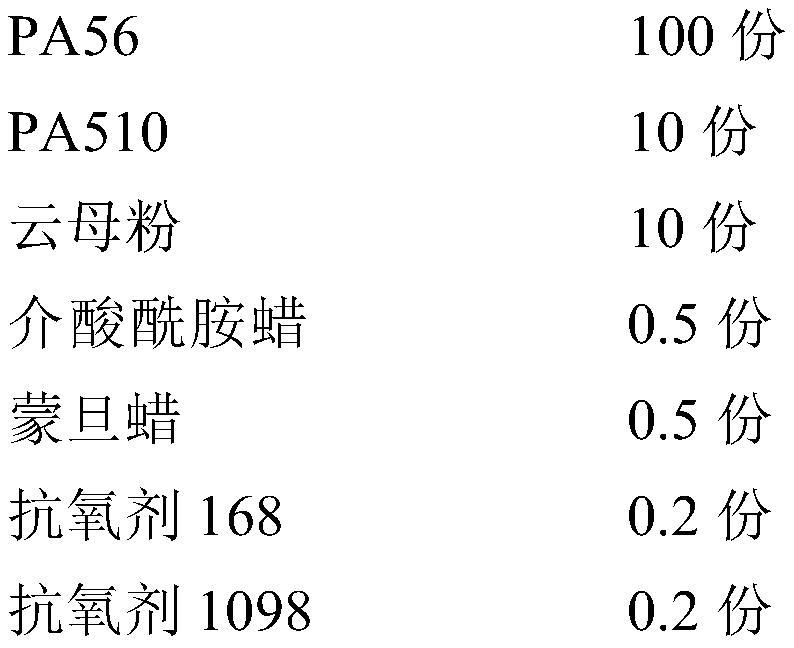

[0066] This embodiment provides a kind of polyamide composition, and its raw material and corresponding parts by weight are:

[0067]

[0068] Accurately weigh each raw material according to the above parts by weight, and fully stir and mix at room temperature to obtain a premix.

[0069] This premix was melt-kneaded by a twin-screw extruder to obtain a melt-kneaded product. The speed of the main screw of the twin-screw extruder is 400 rpm, the speed of the feeding screw is 20 rpm, and it is divided into seven zones for heating. The temperature of zones 1-7 is set as follows: 230°C, 240°C, 250°C , 260°C, 265°C, 265°C, 260°C, and the die temperature is 260°C.

[0070] The molten kneaded material is extruded from the nozzle into strands, and cooled in water to below the melting point of polyamide. The cooled strands were cut by a pelletizer with a rotating speed of 400 rpm to obtain polyamide composition pellets.

Embodiment 2

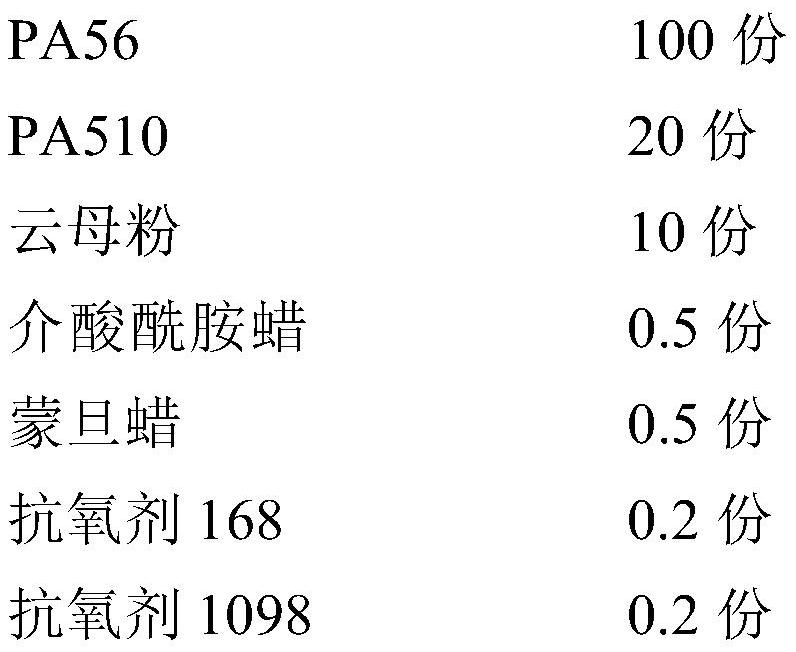

[0072] This embodiment provides a polyamide composition, and its raw materials and corresponding parts by weight are as follows. Using the preparation process in Example 1, the following raw materials were processed to obtain polyamide composition pellets.

[0073]

Embodiment 3

[0075] This embodiment provides a polyamide composition, and its raw materials and corresponding parts by weight are as follows. Using the preparation process in Example 1, the following raw materials were processed to obtain polyamide composition pellets.

[0076]

[0077]

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com