Fabrication of High Thermal Conductivity Polymer Composites with Dense Isolation Structure by Fiber Embedding

A composite material and isolation structure technology, applied in the direction of heat exchange materials, chemical instruments and methods, etc., can solve the problems of insufficient thermal conductivity of the heat conduction network, unimproved material mechanical properties, low thermal conductivity of composite materials, etc., to achieve Conducive to industrial production and application, low production cost, and strong industrialization capabilities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

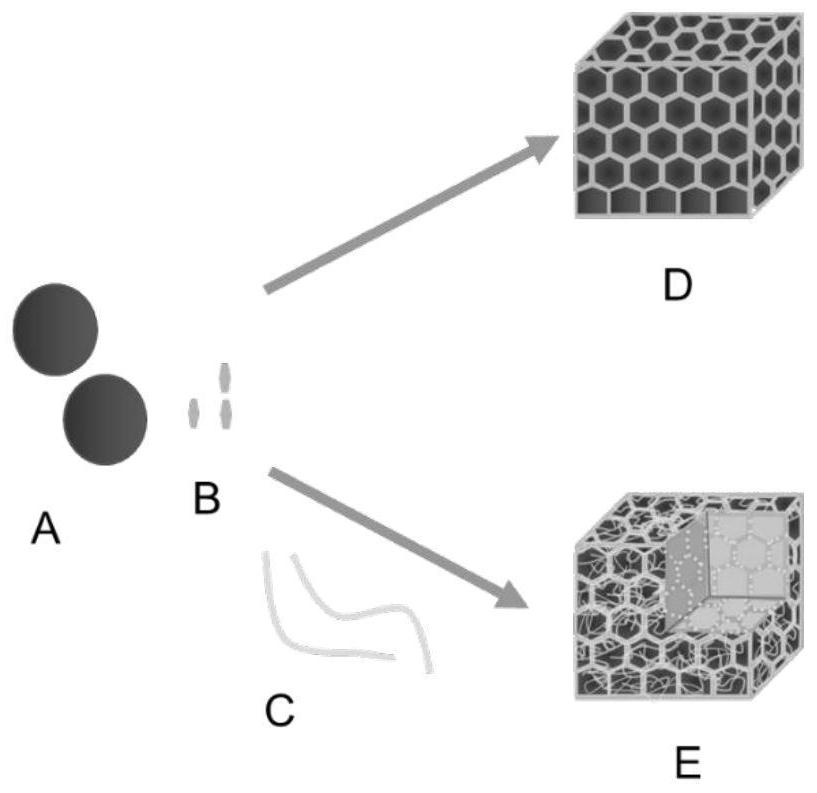

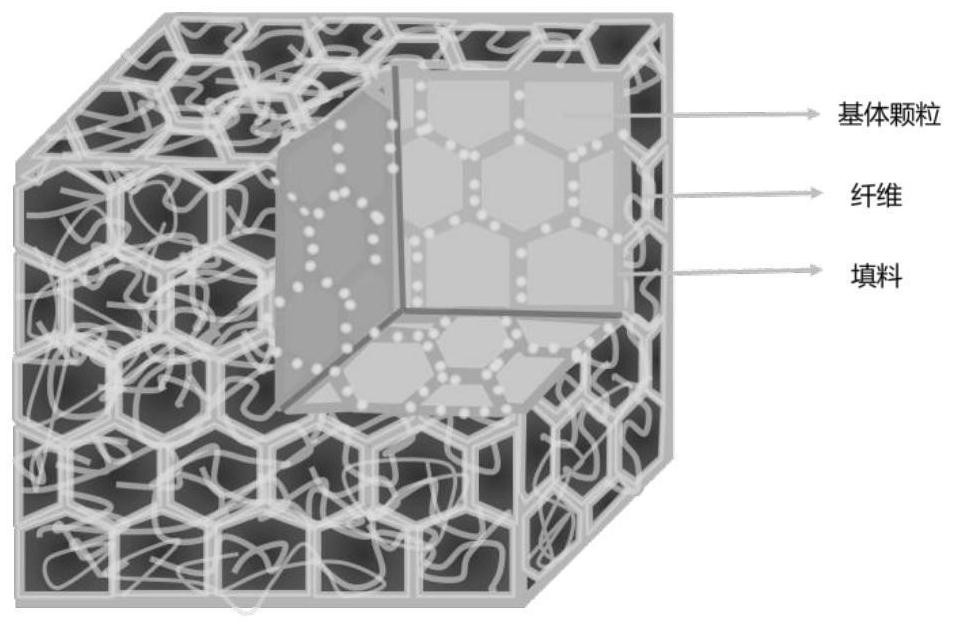

Method used

Image

Examples

Embodiment 1

[0025] (1) Select polypropylene 1003, (China Taiwan Plastics Industry Co., Ltd.), melt index is 0.4g / 10min, particle size is 10 μm; polypropylene fiber (Huixiang Fiber Engineering) length 3mm, diameter is 10 μm; nitriding Boron (Dandong Rijin Technology Co., Ltd.) has a particle size of 10 μm; VAE (705, raw material of Shanghai Yingjia Chemical).

[0026] (2) First, mix 3 mm polypropylene fiber with a polypropylene matrix with a particle size of 10 μm in a mass ratio of 1:9, and at the same time, add VAE adhesive with a total mass ratio of 1:3 to polypropylene and polypropylene fiber to Mix uniformly for 1 min at a speed of 25000 rad / min in a high-speed mixer.

[0027] (3) Add boron nitride with a mass ratio of 2:3 to polypropylene and polypropylene fiber as a thermally conductive filler, continue to mix evenly in a high-speed mixer at a speed of 25000rad / min for 1min, and dry in an oven at 80 degrees for 10h .

[0028] (4) Put the final blend into a mold, press plate at 190...

Embodiment 2

[0031] (1) Select polypropylene 1003, (China Taiwan Plastics Industry Co., Ltd.), melt index is 0.4g / 10min, particle size is 3000 μm; polypropylene fiber (Huixiang Fiber Engineering) length 30mm, diameter is 100 μm; nitriding Boron (Dandong Rijin Technology Co., Ltd.) has a particle size of 20 μm; VAE (705, raw material of Shanghai Yingjia Chemical).

[0032] (2) First, mix 30mm polypropylene fibers with a polypropylene matrix with a particle size of 3000 μm in a mass ratio of 1:9, and at the same time, add VAE adhesive with a total mass ratio of 1:3 to polypropylene and polypropylene fibers in Mix uniformly for 1 min at a speed of 25000 rad / min in a high-speed mixer.

[0033](3) Add boron nitride with a mass ratio of 2:3 to polypropylene and polypropylene fiber as a thermally conductive filler, continue to mix evenly in a high-speed mixer at a speed of 25000rad / min for 1min, and dry in an oven at 80 degrees for 10h .

[0034] (4) Put the final blend into a mold, press plate...

Embodiment 3

[0037] (1) Select polypropylene 1003, (China Taiwan Plastic Industry Co., Ltd.), melt index is 0.4g / 10min, particle size is 10 μm; polypropylene fiber (Huixiang Fiber Engineering) length 3mm, diameter is 10 μm; nitriding Boron (Dandong Rijin Technology Co., Ltd.) has a particle size of 10 μm; VAE (705, raw material of Shanghai Yingjia Chemical).

[0038] (2) First, mix 3 mm polypropylene fiber with a polypropylene matrix with a particle size of 10 μm in a mass ratio of 3:7, and at the same time, add VAE adhesive with a total mass ratio of 1:3 to polypropylene and polypropylene fiber to Mix uniformly for 1 min at a speed of 25000 rad / min in a high-speed mixer.

[0039] (3) Add boron nitride with a mass ratio of 2:3 to polypropylene and polypropylene fiber as a thermally conductive filler, continue to mix evenly in a high-speed mixer at a speed of 25000rad / min for 1min, and dry in an oven at 80 degrees for 10h .

[0040] (4) Put the final blend into a mold, press plate at 190°...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com