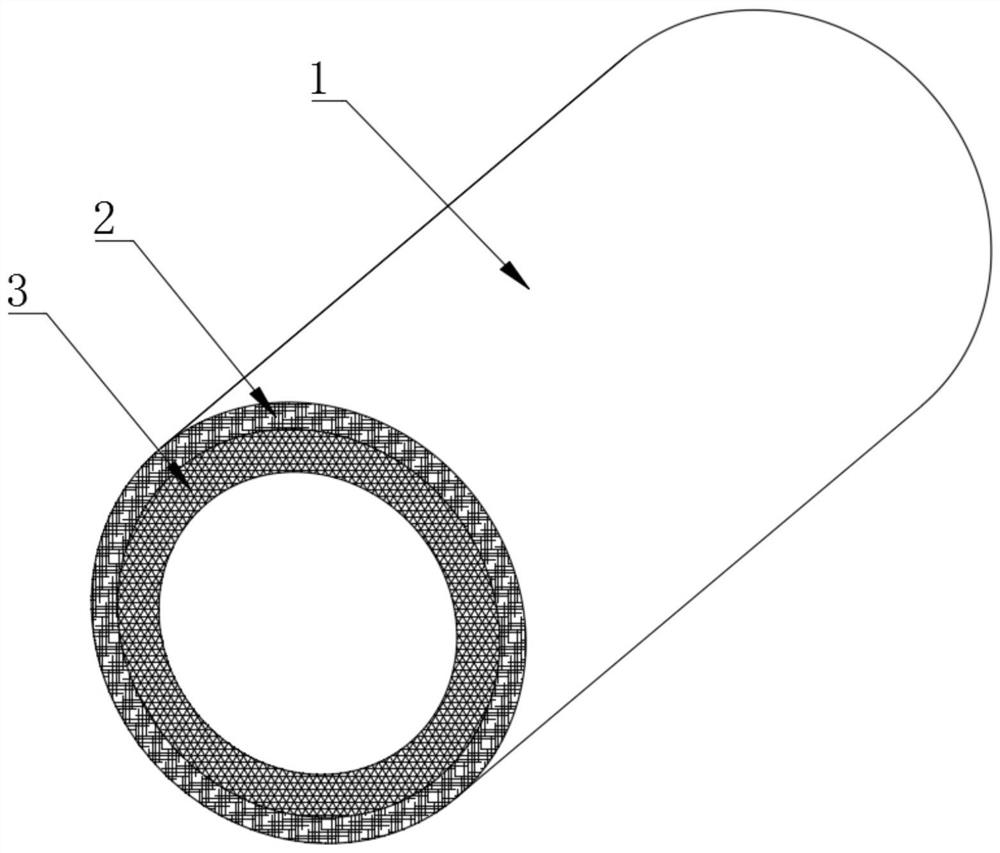

Flexible fireproof pipe for wires and cables and application thereof

A technology for wires, cables and fireproof pipes, applied in electrical components and other directions, can solve problems such as poor water resistance, melting of fireproof materials, and inability to maintain a complete shape.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

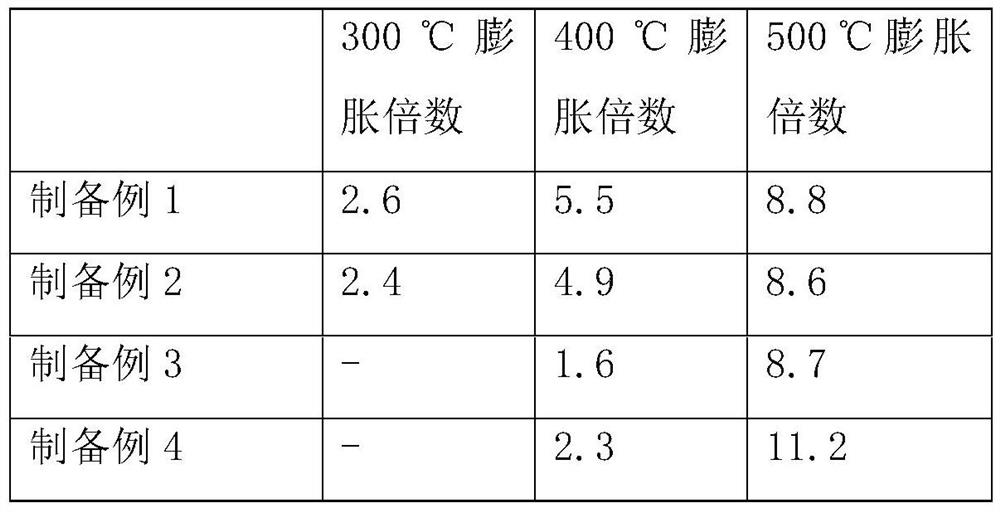

preparation example 1

[0050] Dissolve 0.5 parts of potassium permanganate and 3 parts of sodium dodecylbenzenesulfonate in 40 parts of mixed acid, which is concentrated sulfuric acid, concentrated nitric acid, oxalic acid and benzene trisulfonic acid according to the mass ratio of 5:2:1:3 Mixed acid solution was obtained after stirring and mixing evenly. Add 12 parts of natural flake graphite to the above mixed acid solution, stir and mix evenly, and filter after 6 hours. The filtrate was filtered with 20% hydrogen peroxide, and then washed with pure water until neutral. °C oven dried overnight to obtain the modified expandable graphite, hereinafter referred to as expandable graphite 1.

preparation example 2

[0052] Dissolve 0.5 parts of potassium permanganate and 3 parts of sodium lauryl sulfate in 40 parts of mixed acid, which is a mixture of concentrated sulfuric acid, concentrated nitric acid, oxalic acid and benzenetrisulfonic acid in a mass ratio of 5:2:1:2 , stir and mix evenly to obtain a mixed acid solution, add 12 parts of natural flake graphite to the above mixed acid solution, stir and mix evenly, filter after 6 hours, filter the filtrate with 20% hydrogen peroxide, and then wash with pure water until neutral, at 50 ° C The modified expandable graphite was obtained after drying overnight in an oven, hereinafter referred to as expandable graphite 2.

preparation example 3

[0054] Dissolve 0.5 parts of potassium permanganate in 40 parts of mixed acid. The mixed acid is concentrated sulfuric acid, concentrated nitric acid, oxalic acid and benzene trisulfonic acid according to the mass ratio of 5:2:1:3, and the mixed acid solution is obtained after mixing evenly. Add 12 parts of natural flake graphite to the above mixed acid solution, stir and mix evenly, filter after 6 hours, filter the filtrate with 20% hydrogen peroxide, wash with pure water until neutral, dry in an oven at 50°C overnight to obtain modified expandable graphite , hereinafter referred to as expandable graphite 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com