Polycarboxylate-type high-performance water reducing agent and preparation method thereof

A polycarboxylate-based, high-performance technology, applied in the field of building materials, can solve problems such as insufficient effects and increased costs, achieve significant economic and social benefits, reduce water-cement ratio, and slow down the hydration speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

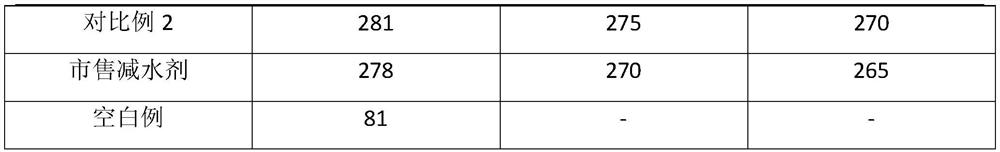

Examples

Embodiment 1

[0027] A polycarboxylic acid-based high-performance water reducer, which is composed of a first component and a second component with a mass ratio of 1:0.5, and the first component is prepared from the following raw materials in parts by weight: no 100 parts of saturated polyoxyethylene ether, 80 parts of methyl acrylate, 10 parts of acrylic acid, 10 parts of oxidizing agent, 1.5 parts of chain transfer agent, 10 parts of reducing agent, 3 parts of liquid caustic soda and 60 parts of deionized water;

[0028] The second component is prepared from the following raw materials in parts by weight: 5 parts of sodium lignosulfonate, 8 parts of diethanol monoisopropanolamine, and 1 part of starch-based hydrogel.

[0029] The starch-based hydrogel is prepared by the following method: weigh 20.0g cornstarch, and form a starch emulsion with a solid content of 5% in a mixed solvent of deionized water and ethanol at a volume ratio of 5:1, and The starch emulsion was heated to 75°C for 30 ...

Embodiment 2

[0042] A polycarboxylic acid-based high-performance water reducer, which is composed of a first component and a second component with a mass ratio of 1:0.5, and the first component is prepared from the following raw materials in parts by weight: no 150 parts of saturated polyoxyethylene ether, 90 parts of methyl acrylate, 20 parts of acrylic acid, 15 parts of oxidizing agent, 2 parts of chain transfer agent, 15 parts of reducing agent, 4 parts of liquid caustic soda and 75 parts of deionized water;

[0043] The second component is prepared from the following raw materials in parts by weight: 8 parts of sodium lignosulfonate, 9 parts of diethanol monoisopropanolamine, and 3 parts of starch-based hydrogel.

[0044] The starch-based hydrogel is prepared by the following method: weigh 20.0g cornstarch, and form a starch emulsion with a solid content of 8% in a mixed solvent of deionized water and ethanol at a volume ratio of 8:1, and The starch emulsion was heated up to 75°C for 7...

Embodiment 3

[0057] A polycarboxylic acid-based high-performance water reducer, which is composed of a first component and a second component with a mass ratio of 1:0.5, and the first component is prepared from the following raw materials in parts by weight: no 200 parts of saturated polyoxyethylene ether, 100 parts of methyl acrylate, 30 parts of acrylic acid, 20 parts of oxidizing agent, 2.5 parts of chain transfer agent, 20 parts of reducing agent, 5 parts of liquid caustic soda and 90 parts of deionized water;

[0058] The second component is prepared from the following raw materials in parts by weight: 10 parts of sodium lignosulfonate, 10 parts of diethanol monoisopropanolamine, and 5 parts of starch-based hydrogel.

[0059] The starch-based hydrogel is prepared by the following method: weigh 20.0g cornstarch, and form a starch emulsion with a solid content of 10% in a mixed solvent of deionized water and ethanol at a volume ratio of 10:1, and The starch emulsion was heated to 75°C f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com