Novel CO2-EGS mode high-temperature corrosion-resistant well cementation cement system for hot dry rock

A CO2-EGS and cementing technology, applied in the field of oil and gas well cementing, can solve the problems of high temperature strength stability, low thermal conductivity, and inability to effectively meet the performance requirements of dry hot rock high temperature cementing cement, and achieve good compressive strength Stability and admixture adaptability, good high temperature admixture adaptability, effect of improving high temperature strength stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

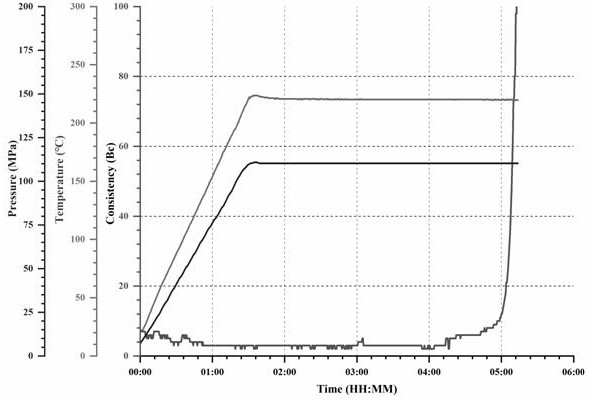

Image

Examples

Embodiment 1

[0031] A new type of CO 2 -The EGS model high-temperature anti-corrosion cementing cement system for dry hot rocks, involving the field of oil and gas well cementing technology, using low-calcium-silicon-ratio cement as the base cement, C 2 The S content is 50.2%, and the specific surface area is 283m 2 / Kg, 7d heat of hydration ≤ 182kJ / kg; the waste concrete is crushed and ground, and the fineness of the powder is controlled to 300 mesh, and the SiO in the powder 2 The content is 73.4%; anti-CO2 The corrosion material is mica powder, the specific composition is as follows:

[0032]

[0033] Take raw materials according to the specific composition ratio in the above table, mix them, and prepare cement slurry according to GB / T 19139, with a water-cement ratio of 0.45, to obtain a well cementing cement system.

Embodiment 2

[0035] The present embodiment adopts low-calcium-silicon ratio cement as base cement, and the specific composition is as follows:

[0036]

[0037] Take raw materials according to the specific composition ratio in the above table, mix them, and prepare cement slurry according to GB / T 19139, with a water-cement ratio of 0.45, to obtain well cementing cement slurry.

Embodiment 3

[0039] In this embodiment, cement with low heat of hydration is used as the base cement, and cement with low heat of hydration is used as the base cement. C 2 The S content is 44.5%, and the specific surface area is 325m 2 / Kg, 7d hydration heat ≤ 216kJ / kg, the specific composition is as follows:

[0040]

[0041] Take raw materials according to the specific composition ratio in the above table, mix them, and prepare cement slurry according to GB / T 19139, with a water-cement ratio of 0.45, to obtain well cementing cement slurry.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Heat of hydration | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com