Potassium air regeneration medicine plate and manufacturing method thereof

A manufacturing method and technology of medicine plates, which are applied in the directions of oxygen preparation, separation methods, chemical instruments and methods, etc., can solve the problems of affecting the forming effect of medicine plates, poor performance of medicine plates, and easy collapse.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

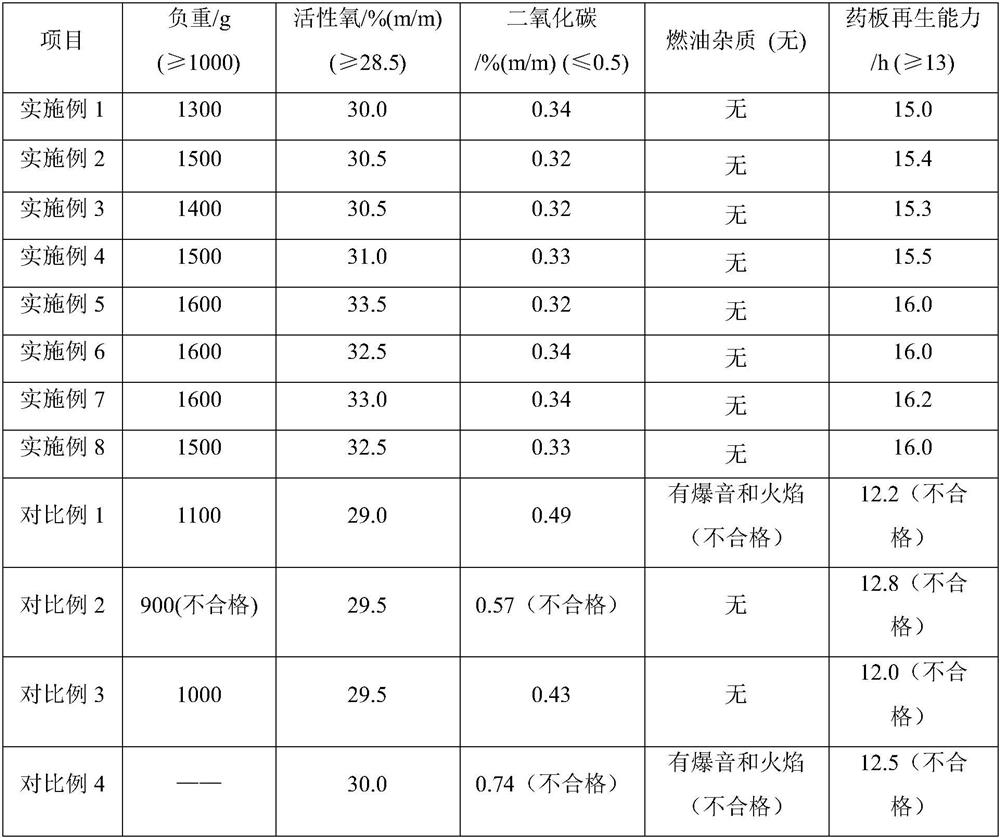

Examples

Embodiment 1

[0035] A kind of Potassium air regenerating medicine board, it is made through following manufacturing steps:

[0036] (1) Chrysotile impurity removal: Weigh 300 g of chrysotile after deslagging, and heat it at 400°C for 2.5 hours to remove moisture and organic oil; in an environment with a relative humidity of 35%, within 5 minutes, Chrysotile is cooled to 25°C to obtain chrysotile after removal of impurities; among them, chrysotile has a tensile strength of 2800MPa and a hardness of 2.1;

[0037] (2) mixing: the chrysotile and potassium superoxide 9kg after the above-mentioned impurity removal are stirred and mixed evenly to obtain a mixing;

[0038] (3) Medicine board pressing: Weigh 385g of the above-mentioned mixture each time and pour it into the feeding frame, break it up with tweezers, spread it evenly and cover it with a metal plate, spread enough nine medicine boards in each frame, and the last piece of each frame All the above are covered with a flat metal plate; t...

Embodiment 2

[0041] A kind of Potassium air regenerating medicine board, it is made through following manufacturing steps:

[0042] (1) Impurity removal of chrysotile: Weigh 300 g of chrysotile after deslagging and heat treatment at 410° C. for 2 hours to remove moisture and organic oil; Asbestos is cooled to 23°C to obtain chrysotile after removal of impurities; among them, the tensile strength of chrysotile is 2800MPa, and the hardness is 2.1;

[0043] (2) mixing: the chrysotile and potassium superoxide 9kg after the above-mentioned impurity removal are stirred and mixed evenly to obtain a mixing;

[0044] (3) Medicine board pressing: Weigh 385g of the above-mentioned mixture each time and pour it into the feeding frame, break it up with tweezers, spread it evenly and cover it with a metal plate, spread enough nine medicine boards in each frame, and the last piece of each frame All the above are covered with a flat metal plate; then the mixture is pressed and formed with a hydraulic pre...

Embodiment 3

[0047] A kind of Potassium air regenerating medicine board, it is made through following manufacturing steps:

[0048] (1) Chrysotile impurity removal: Weigh 300 g of chrysotile after deslagging and heat treatment at 420°C for 1.5 hours to remove water and organic oil; in an environment with a relative humidity of 33%, within 15 minutes Chrysotile is cooled to 20°C to obtain chrysotile after removal of impurities; among them, chrysotile has a tensile strength of 2800MPa and a hardness of 2.1;

[0049] (2) mixing: the chrysotile and potassium superoxide 9kg after the above-mentioned impurity removal are stirred and mixed evenly to obtain a mixing;

[0050] (3) Medicine board pressing: Weigh 385g of the above-mentioned mixture each time and pour it into the feeding frame, break it up with tweezers, spread it evenly and cover it with a metal plate, spread enough nine medicine boards in each frame, and the last piece of each frame All the above are covered with a flat metal plate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com