Method for manufacturing flux-cored wire, flux-cored wire and method for manufacturing welded joint

A technology of flux-cored welding wire and manufacturing method, applied in welding medium, manufacturing tool, welding equipment, etc., can solve problems such as peeling of coating film

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0130] The effects of the present invention will be described in more detail below through examples.

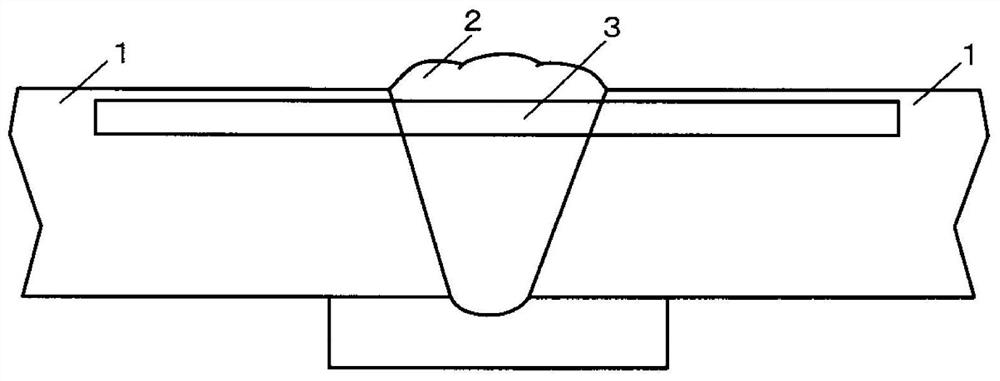

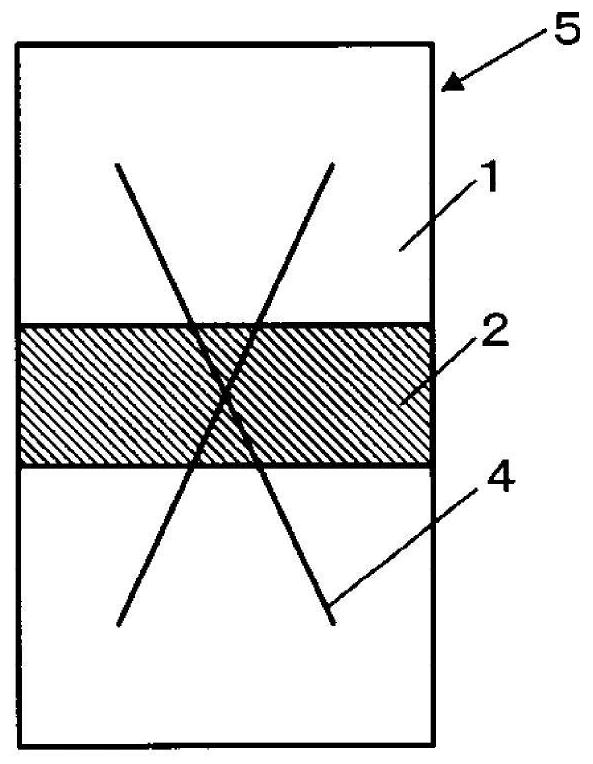

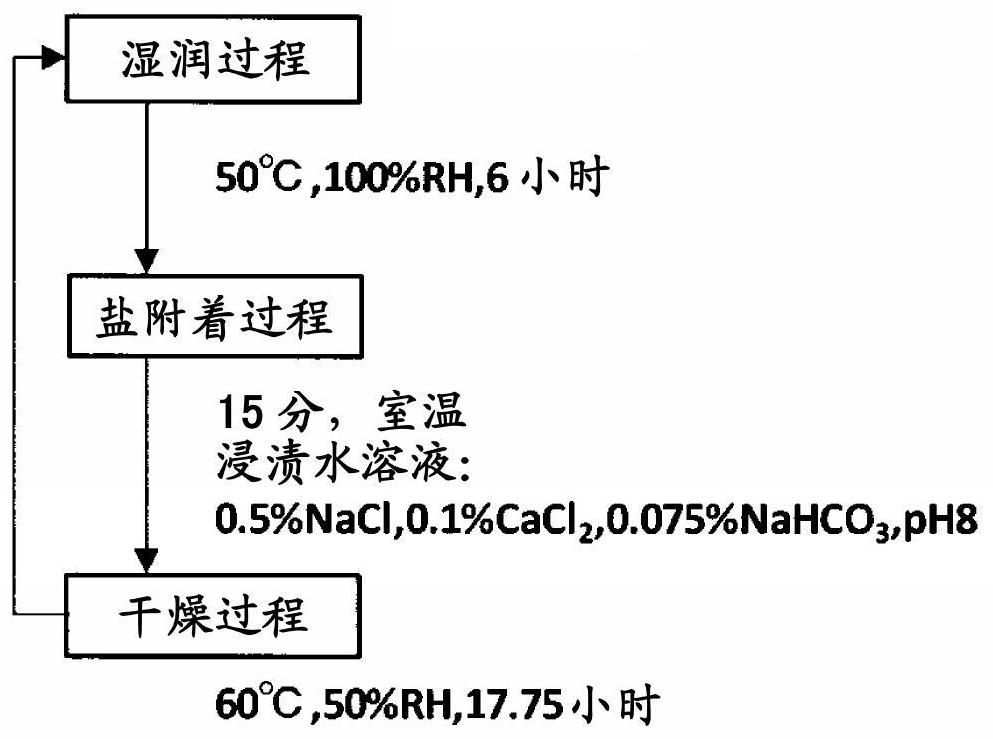

[0131] SPCC specified in JIS G 3141:2011 "Cold-rolled steel sheets and steel bands" is used as a steel sheath, filled with flux, and then reduced in diameter (for softening and dehydrogenation of the sheath, intermediate annealing is performed once) , various seamless flux-cored wires were trial-produced. The various seamless flux-cored wires have the components shown in Table 1-1 to Table 1-3, the filling rate is 13.5%, and the wire diameter is 1.2 mm, there is no through-through gap on the steel skin, which is the seamless type. However, A23 is manufactured by riveting. It should be noted that the numerical values in Tables 1-1 to 1-3 represent mass % with respect to the total mass of the flux-cored wire (total mass of the steel sheath and flux). In addition, the values described in Table 1-1 to Table 1-3 are design values. In the manufacture of the flux-cored wire, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Film thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com