Hot-melt OCA optical adhesive film and preparation method thereof

A hot-melt, optical adhesive technology, applied in the field of OCA optical adhesive, which can solve the problems of air bubbles and glue pulling, indentation, air bubbles, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] Example 1: A hot-melt OCA optical adhesive film and its preparation method

[0052] Hot-melt OCA optical adhesive film is an optical-grade material with hot-melt resin and silicone resin as the main body. The hot-melt resin includes thermoplastic resin, and the silicone resin includes: reactive methylphenylpolysiloxane, methyl phenyl T resin, methylphenyl silicone resin, phenyl crosslinking agent, phenyl chain extender and additives; among them, in thermoplastic resin and silicone resin:

[0053] The basic condition is 1 / 5≤M (hot-melt resin) / M (organic silicon resin)≤1 / 2, where M (hot-melt resin) is the total mass of hot-melt resin, M (silicone resin) is the total mass of the silicone resin. In this embodiment, M (hot-melt resin) / M (organic silicon resin)=0.3.

[0054] In terms of mass fraction, in silicone resin:

[0055] Reactive methyl phenyl polysiloxane 75%,

[0056] Methyl phenyl T resin 10%;

[0057] Methylphenyl silicone resin 10%;

[0058] Phenyl crosslin...

Embodiment 2

[0096] Example 2: A hot-melt OCA optical adhesive film and its preparation method

[0097] A hot-melt type OCA optical adhesive film, the raw material formula of the hot-melt type OCA optical adhesive film includes a hot-melt resin and a silicone resin, and the ratio of the total mass of the hot-melt resin to the total mass of the silicone resin is 0.35; The raw material formulation of the silicone resin includes the raw materials of the following mass fractions

[0098] Reactive methyl phenyl polysiloxane 50%;

[0099] Methyl phenyl T resin 37%;

[0100] Methylphenyl silicone resin 10%;

[0101] Phenyl crosslinking agent 1%;

[0102] Phenyl chain extender 1%;

[0103] Additive 1%.

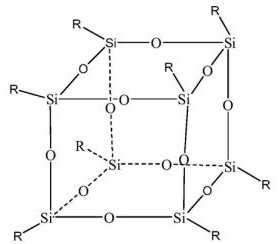

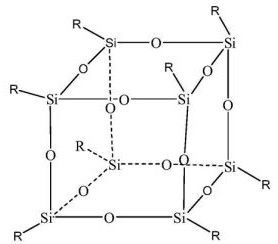

[0104] A preferred embodiment is: the hot-melt resin includes a mixture of thermosetting resin and thermoplastic resin in a mass ratio of 1:1; the thermosetting resin is POSS resin; the general formula of POSS resin is as follows:

[0105]

[0106] The groups represented by R are differen...

Embodiment 3

[0135] Example 3: A hot-melt OCA optical adhesive film and its preparation method

[0136] A hot-melt type OCA optical adhesive film, the raw material formula of the hot-melt type OCA optical adhesive film includes a hot-melt resin and a silicone resin, and the ratio of the total mass of the hot-melt resin to the total mass of the silicone resin is equal to; The raw material formula of silicone resin includes the following mass fractions of raw materials

[0137] Reactive methyl phenyl polysiloxane 63%;

[0138] Methyl phenyl T resin 13.5%;

[0139] Methylphenyl silicone resin 15%;

[0140] Phenyl crosslinking agent 3%;

[0141] Phenyl chain extender 3%;

[0142] Additives 2.5%.

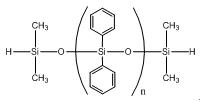

[0143] A preferred embodiment is: the hot-melt resin is a mixture of thermosetting resin and thermoplastic resin in a mass ratio of 1:3; the thermosetting resin is MQ resin;

[0144] The general formula of MQ resin is (Me 3 SiO 1 / 2 ) n (PhSiO 3 / 2 ) m , Me represents methyl, Ph represents p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

| haze | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com