Modification method of nano material for high-viscosity coating, and preparation method and application of corona-resistant composite coating

A nanomaterial and composite coating technology, applied in coatings, circuits, electrical components, etc., can solve the problems of poor compatibility of the main polymer of the coating, weak stability, and weakened corona resistance effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Example 1 A nanomaterial modification method for high-viscosity coatings

[0039]1. Weigh 20 mol of phenol and 10 mol of 50nm silica, add them to 100 mol of xylene respectively, heat up to 30°C, keep warm and activate for 24 hours to obtain material A1;

[0040] 2. Weigh 10 mol of material A1 and add it to 200 mol of octene, heat to 80 °C under the pressure of 0.5 Mpa and nitrogen protection, and keep warm for grafting reaction for 1 h to obtain material B1;

[0041] 3. Weigh 100 mol of material B1, wherein, in order to disperse material B1 evenly, divide material B1 into 5~8 parts, add them to 500 mol of toluene respectively, continue to add 10 mol of KH550, under the protection of argon, heat up To 20 ℃, insulation modification for 48h, the modified nanomaterials are obtained.

Embodiment 2~8

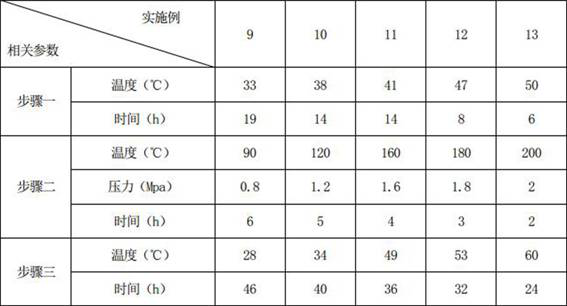

[0042] Embodiment 2~8 are used for the modification method of the nanometer material of high-viscosity coating

[0043] The operation steps of Examples 2-8 are the same as those of Example 1, and the only difference is that the raw materials used and the amount of raw materials are different. The relevant raw materials and the amount of raw materials are shown in Table 1.

[0044] Table 1

[0045]

[0046]

Embodiment 9~13

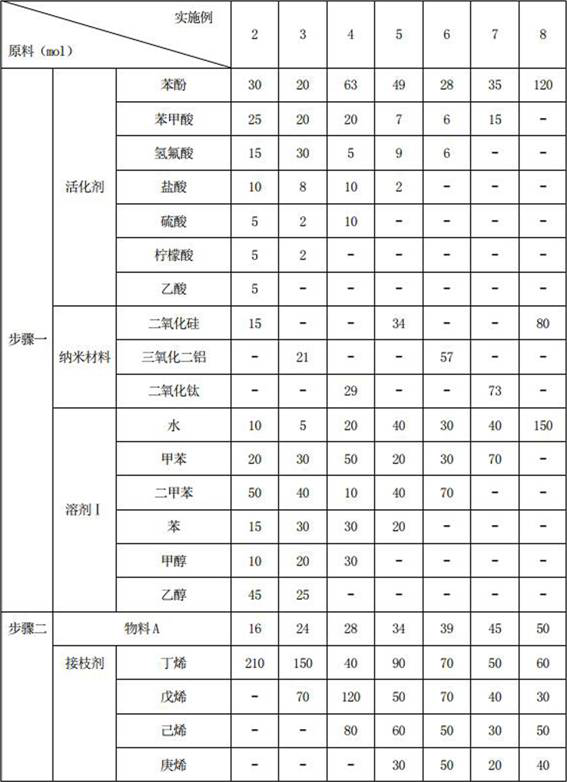

[0047] Embodiment 9~13 are used for the modification method of the nanometer material of high-viscosity coating

[0048] Examples 9-13 are the same as those in Example 1 with the same raw materials, raw material consumption and operation steps, the only difference is that the relevant parameters in the operation steps are different, and the relevant parameter data are shown in Table 2.

[0049] Table 2

[0050]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com