Liquid metal conductive composition for screen printing, and preparation method and application thereof

A conductive composition and liquid metal technology, applied in applications, printed circuits, metal pattern materials, etc., can solve the problems of reducing the conductivity of devices, complicated integration steps, and poor energy storage performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

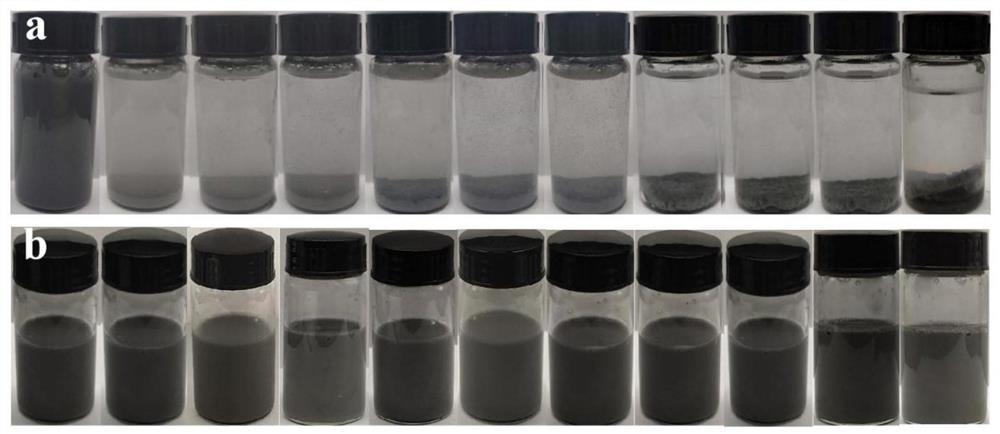

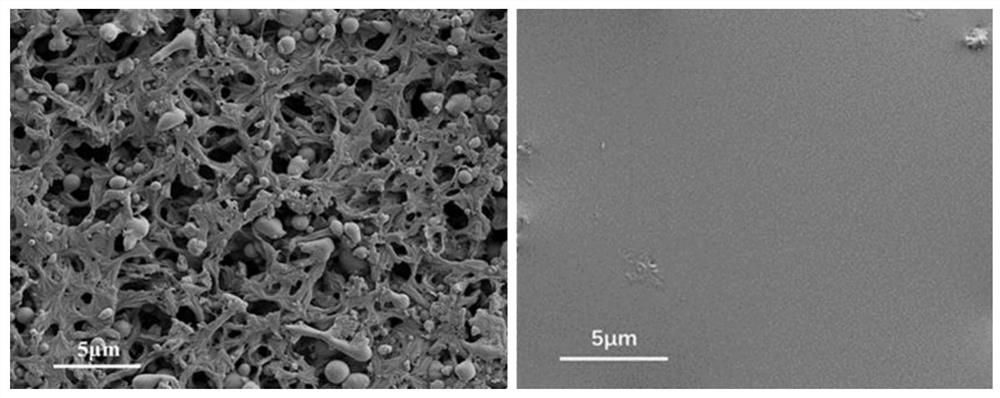

[0047] The preparation method of the liquid metal conductive composition for screen printing, the specific process is as follows:

[0048] (1) Preparation of silk fibroin: silkworm cocoons are degummed, dissolved, dialyzed, and freeze-dried to obtain pure silk fibroin, specifically:

[0049] a, silkworm cocoon degumming: use Na 2 CO 3 The solution was boiled at 100°C for 40 minutes with a bath ratio of 1:40, and repeated 4 times to obtain degummed silk fibroin;

[0050] b. Silk fibroin dissolution: prepare CaCl 2 :H 2 O: C 2 h 5 Mixed solvent with OH molar ratio of 1:2:8, put silk fibroin in a bath ratio of 1:10, put it in a water bath at 75±2°C and stir it at constant temperature until it is completely dissolved to obtain brown-yellow silk fibroin-calcium chloride solution;

[0051] c. Dialysis: import the silk fibroin-calcium chloride solution obtained in step b into a clean dialysis bag, dialyze with water for 3-7 days, remove solid impurities by centrifugal filtrati...

Embodiment 2

[0061] The preparation method of the liquid metal conductive composition for screen printing, the specific process is as follows:

[0062] (1) preparation of silk fibroin: with embodiment 1;

[0063] (2) Preparation of silk fibroin aqueous solution: mix silk fibroin (0.8 g) obtained in step (1) with deionized water (22 mL), and magnetically stir at 60° C. for 6 hours to obtain silk fibroin aqueous solution;

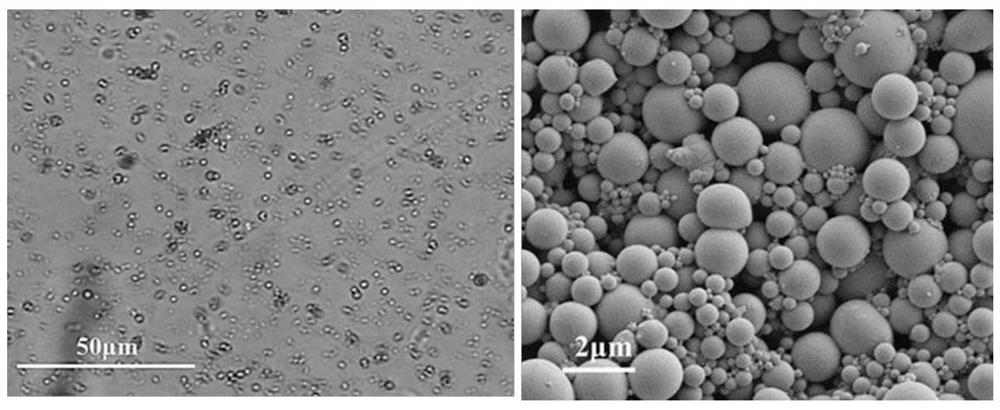

[0064] (3) Preparation of conductive ink: add 2.15 g of gallium-indium alloy to the silk fibroin aqueous solution obtained in step (2), in an ice bath environment, ultrasonic 30min, to obtain conductive ink;

[0065] (4) Paste preparation: Add 0.25 g of polyvinylpyrrolidone to the conductive ink obtained in step (3), and stir for 25 minutes to obtain a liquid metal conductive paste for screen printing.

Embodiment 3

[0067] The preparation method of the liquid metal conductive composition for screen printing, the specific process is as follows:

[0068] (1) preparation of silk fibroin: with embodiment 1;

[0069] (2) Preparation of silk fibroin aqueous solution: mix the silk fibroin (1 g) obtained in step (1) with deionized water (28 mL), and stir magnetically at 55° C. for 5.5 hours to obtain an aqueous silk fibroin solution;

[0070] (3) Preparation of conductive ink: add 2.15g of gallium-indium alloy to the silk fibroin aqueous solution obtained in step (2), in an ice bath environment, ultrasonic 25min, to obtain conductive ink;

[0071] (4) Paste preparation: Add 0.38 g of carboxymethyl cellulose (CMC) to the conductive ink obtained in step (3), and stir for 60 minutes to obtain a liquid metal conductive paste for screen printing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com