Humic acid-containing foliar fertilizer based on biogas slurry as well as preparation method and application thereof

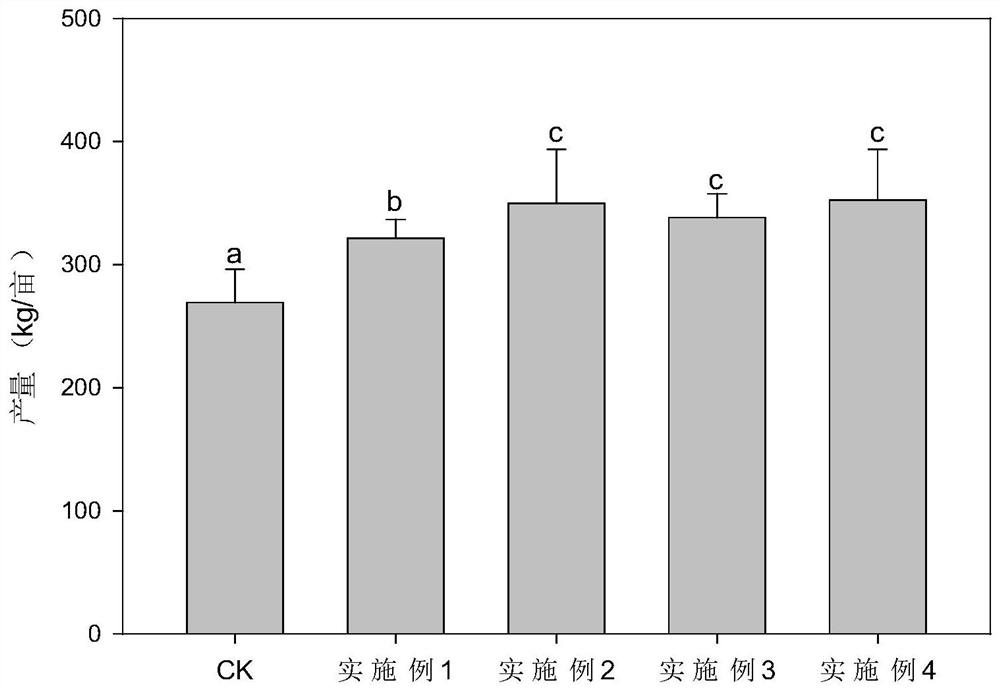

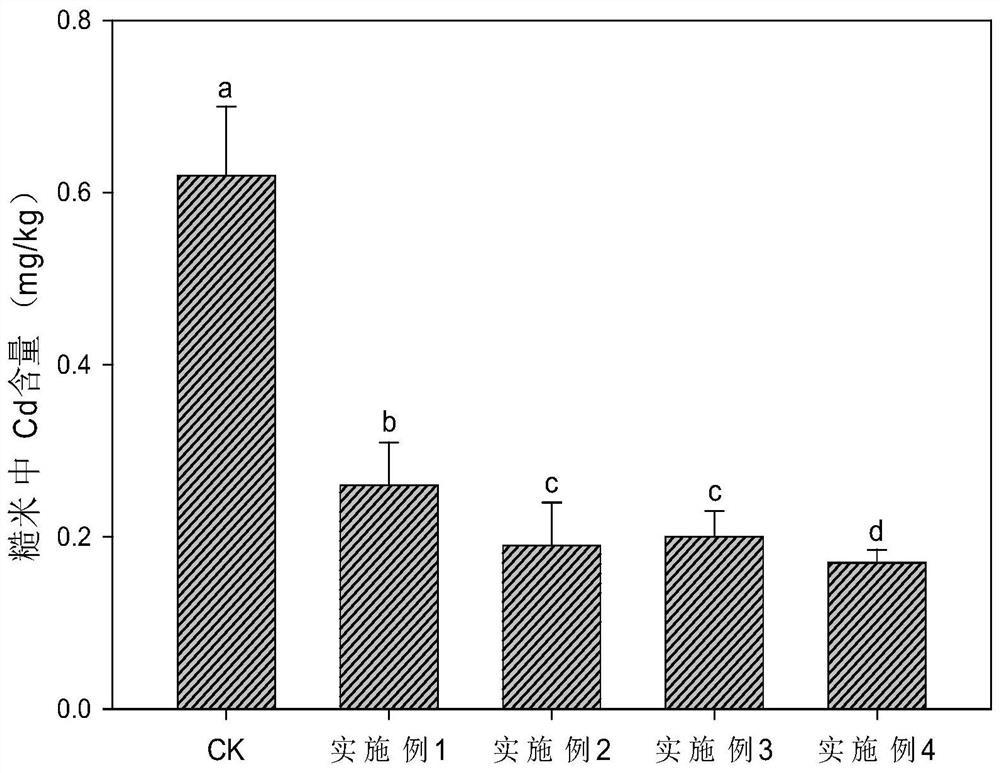

A humic acid and foliar fertilizer technology, applied in fertilization methods, applications, liquid fertilizers, etc., can solve problems such as unsatisfactory technical indicators and application methods, difficulty in large-scale production and popularization and application, and failure to meet product technical indicators. The effect of preventing heavy metal absorption of diseased crops, inhibiting heavy metal absorption of crops, and enhancing lodging resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0070] A humic acid-containing foliar fertilizer based on biogas slurry, comprising the following components by mass: 80 kg of humic acid-containing organic mother liquor, 20 kg of urea, 10 kg of potassium dihydrogen phosphate, 20 kg of potassium chloride, and 26 kg of trace metal element solution; The described humic acid-containing organic mother liquor includes the following components in parts by weight: biogas slurry concentrate 70kg, potassium humate 6kg, and potassium citrate 4kg; the trace metal element formulation includes the following components in parts by weight : Deionized water 25kg, zinc chloride 0.3kg, magnesium chloride 0.2kg, calcium chloride 0.3kg, EDDHA chelated iron 0.2kg.

[0071] The preparation method of the described biogas slurry-containing humic acid foliar fertilizer comprises the following steps:

[0072] (1) Preparation of humic acid-containing organic mother liquor: weigh and mix biogas slurry concentrate, potassium citrate, and potassium humate...

Embodiment 2

[0076] A humic acid-containing foliar fertilizer based on biogas slurry, including the following components in parts by mass: 100kg of humic acid-containing organic mother liquor, 30kg of urea, 20kg of potassium dihydrogen phosphate, 30kg of potassium chloride, and 5.25kg of trace metal element solution; The organic mother liquor containing humic acid includes the following components in parts by weight: biogas slurry concentrate 80kg, potassium humate 12kg, and potassium citrate 8kg; the trace metal element formulation includes the following components in parts by weight Divide: deionized water 5kg, zinc chloride 0.05kg, magnesium chloride 0.05kg, calcium chloride 0.1kg, EDDHA chelated iron 0.05kg.

[0077] The preparation method of the described biogas slurry-containing humic acid foliar fertilizer comprises the following steps:

[0078] (1) Preparation of humic acid-containing organic mother liquor: weigh and mix biogas slurry concentrate, potassium citrate, and potassium h...

Embodiment 3

[0082] A humic acid-containing foliar fertilizer based on biogas slurry, including the following components in parts by mass: 90kg of humic acid-containing organic mother liquor, 25kg of urea, 15kg of potassium dihydrogen phosphate, 25kg of potassium chloride, and 15.5kg of trace metal element solution; The organic mother liquor containing humic acid includes the following components in parts by weight: biogas slurry concentrate 75kg, potassium humate 9kg, and potassium citrate 6kg; the trace metal element formulation includes the following components in parts by weight Divide: deionized water 15kg, zinc chloride 0.1kg, magnesium chloride 0.1kg, calcium chloride 0.2kg, EDDHA chelated iron 0.1kg.

[0083] The preparation method of the described biogas slurry-containing humic acid foliar fertilizer comprises the following steps:

[0084](1) Preparation of humic acid-containing organic mother liquor: weigh and mix biogas slurry concentrate, potassium citrate, and potassium humate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com