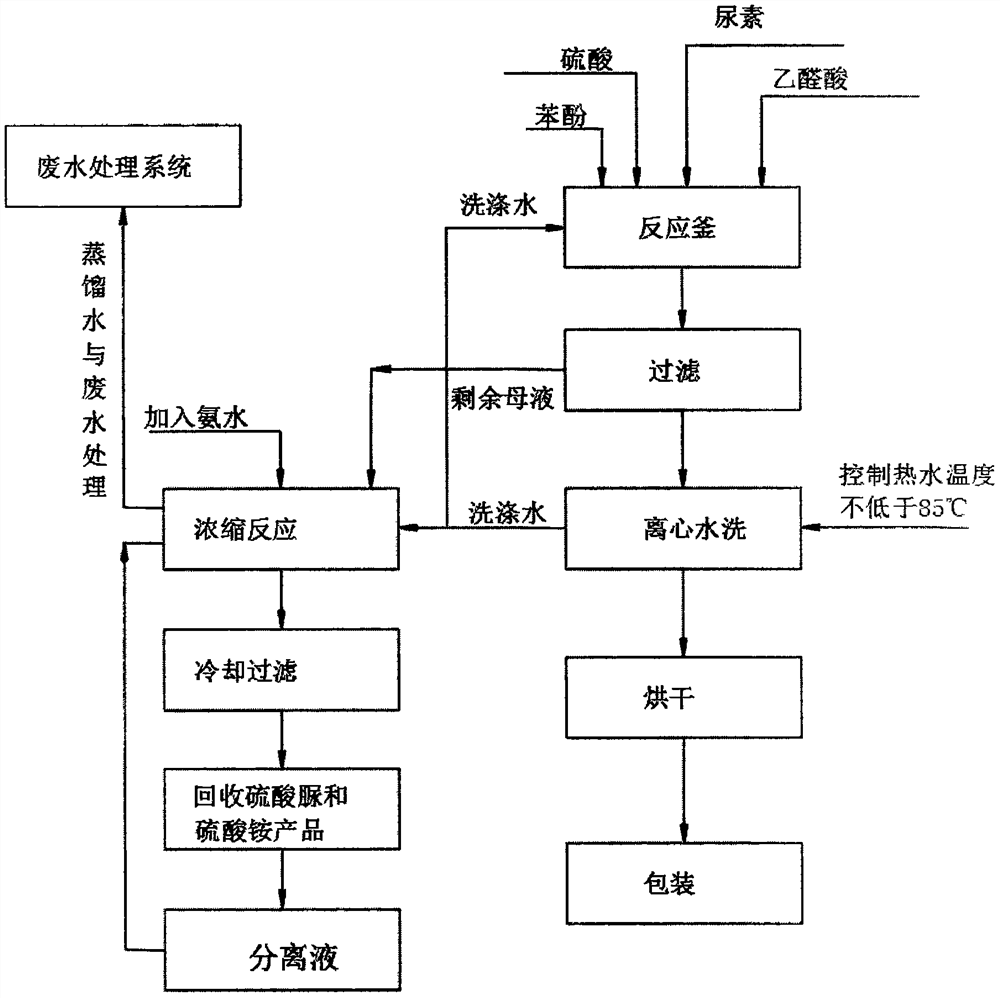

Production process of DL-p-hydroxybenzene hydantoin and urea sulfate/ammonium sulfate thereof

A technology for p-hydroxybenzohydantoin and production process, which is applied in the field of DL-p-hydroxybenzohydantoin and its urea sulfate/ammonium sulfate production technology, can solve the problems of large amount of solid waste, high cost, difficult three waste treatment and the like, and achieves the Reduce the cost of wastewater treatment, improve product quality and yield, and solve the effect of large amount of solid waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

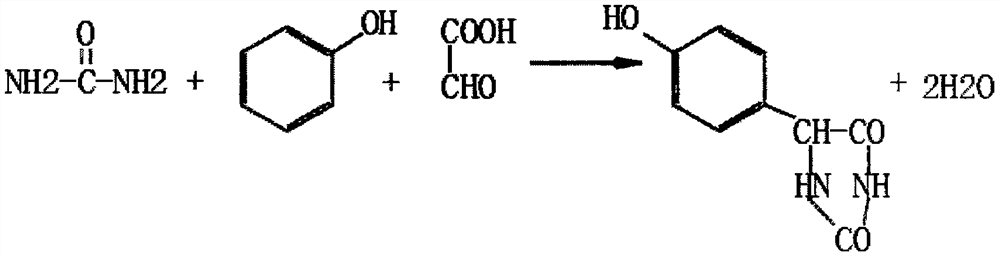

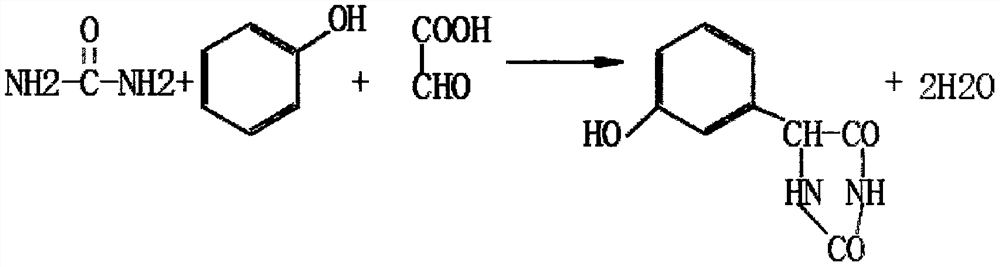

Method used

Image

Examples

Embodiment 1

[0046] In a 250mL four-necked flask equipped with mechanical stirring, reflux condenser, thermometer, and dropping funnel, add 37g of urea, 20g of phenol, and 40mL of sulfuric acid with a concentration of 75% in sequence. Under stirring, the reaction temperature is controlled at 80°C. Slowly add 30g of weighed 40% glyoxylic acid solution dropwise, control the dropping time for about 4 hours, and the reaction temperature is not lower than 85°C; Crystals; filter with Buchner funnel, wash the filter cake 3 times with 50mL of hot water not lower than 85°C, filter with suction until there is no free water on the surface of the filter cake, put the filter cake in a drying oven and dry until the water content is less than If it is higher than 0.5%, 25g of DL-p-hydroxyphenylhydantoin is obtained, the purity is above 98.5%, and the mass yield (calculated as phenol) is 85%.

Embodiment 2

[0048]In a 2000mL beaker equipped with a mechanical stirrer, a thermometer, and a dropping funnel, react 200mL of the mother liquor, then add 150g of urea, 73g of phenol, and 125mL of sulfuric acid with a concentration of 36% in sequence. Add 110g of the weighed 40% glyoxylic acid solution dropwise, control the dropping time for about 4 hours, and the reaction temperature is not lower than 85°C; after the dropping reaction is completed, keep stirring for 30 minutes, cool the reaction solution to room temperature, and white crystals are precipitated filter with Buchner funnel, wash the filter cake three times with 150mL of hot water not lower than 85°C, filter until there is no free water on the surface of the filter cake, put the filter cake in a drying oven and dry until the water content is not high At 0.5%, 92 g of DL-p-hydroxyphenylhydantoin was obtained with a purity of over 98.5% and a mass yield (calculated as phenol) of 85%.

Embodiment 3

[0050] Step 1. In a 2000L enamel reaction kettle, use 500L of the mother liquor, start stirring, then add 250Kg of urea, 170Kg of phenol, and 180L of sulfuric acid with a concentration of 60% into the reaction kettle, slowly control the reaction temperature at 90°C, and keep it warm for 30min;

[0051] Step 2. After the heat preservation is over, add 255Kg of weighed 50% glyoxylic acid dropwise to the reaction kettle, control the reaction temperature in the kettle not to exceed 90°C, and drop the time for not less than 4 hours;

[0052] Step 3. After the dropwise addition reaction, control the reaction temperature not lower than 85°C and keep it warm for 30 minutes; then lower the temperature to 85°C and prepare to discharge;

[0053] Step 4. Put the material in the reaction kettle into the prepared filter, and suction filter until there is no visible water drop on the surface of the material, and then move the material to the prepared centrifuge while it is hot;

[0054] Step...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com