High-strength water-resistant soil consolidation agent

A soil consolidation agent, high-strength technology, applied in the field of building materials, can solve problems such as expansion and cracking of concrete buildings, affecting the safety and service life of buildings, and accelerating chemical corrosion of cement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

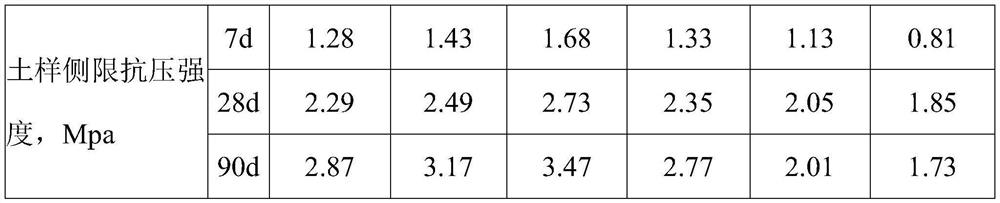

Embodiment 1

[0018] 50 parts of Portland cement, 17 parts of composite superfine powder, 2 parts of accelerator, 10 parts of polymer cellulose, 21 parts of modified polypropylene, 6 parts of alkali-free glass fiber; It is made of slag powder, fly ash, desulfurized gypsum, metakaolin, coal gangue and polydimethylsiloxane at the ratio of 20:10:10:5:12:40, and the particle size D50 of the material is below 8 μm. D95 is less than 20μm, and the specific surface area is 850-900m2 2 / kg;

[0019] Among them, the polymer cellulose is hydroxypropyl methylcellulose and polyvinyl alcohol fiber with a mass ratio of 5:2; the Portland cement is a mixture of sulphoaluminate cement and ordinary Portland cement Compound cement, sulfoaluminate cement accounts for 7-9% of the total mass of cement, and the balance is ordinary Portland cement; the alkali-free glass fiber is a powder with a diameter of 9-13 μm and a length of 30-50 μm; The quick-setting agent is prepared from sodium aluminate, sodium carbonat...

Embodiment 2

[0021] 82 parts of Portland cement, 38 parts of composite ultrafine powder, 9 parts of accelerator, 16 parts of polymer cellulose, 24 parts of modified polypropylene, 10 parts of alkali-free glass fiber; It is made of slag powder, fly ash, desulfurized gypsum, metakaolin, coal gangue and polydimethylsiloxane at the ratio of 30:22:15:8:18:60, and the particle size D50 of the material is below 8 μm. D95 is less than 20μm, and the specific surface area is 850-900m2 2 / kg;

[0022] Among them, the polymer cellulose is hydroxypropyl methylcellulose and polyvinyl alcohol fiber with a mass ratio of 5:12; the Portland cement is a mixture of sulphoaluminate cement and ordinary Portland cement Compound cement, sulfoaluminate cement accounts for 7-9% of the total mass of cement, and the balance is ordinary Portland cement; the alkali-free glass fiber is a powder with a diameter of 9-13 μm and a length of 30-50 μm; The quick-setting agent is prepared from sodium aluminate, sodium carbon...

Embodiment 3

[0024] 65 parts of Portland cement, 20 parts of composite superfine powder, 6 parts of accelerator, 13 parts of macromolecular cellulose, 22 parts of modified polypropylene, 8 parts of alkali-free glass fiber; It is made of slag powder, fly ash, desulfurized gypsum, metakaolin, coal gangue and polydimethylsiloxane at the ratio of 22:12:12:6:15:45, and the particle size D50 of the material is below 8 μm. D95 is less than 20μm, and the specific surface area is 850-900m2 2 / kg;

[0025] Among them, the polymer cellulose is hydroxypropyl methylcellulose and polyvinyl alcohol fiber with a mass ratio of 5:8; the Portland cement is a mixture of sulphoaluminate cement and ordinary Portland cement Compound cement, sulfoaluminate cement accounts for 7-9% of the total mass of cement, and the balance is ordinary Portland cement; the alkali-free glass fiber is a powder with a diameter of 9-13 μm and a length of 30-50 μm; The quick-setting agent is prepared from sodium aluminate, sodium c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com