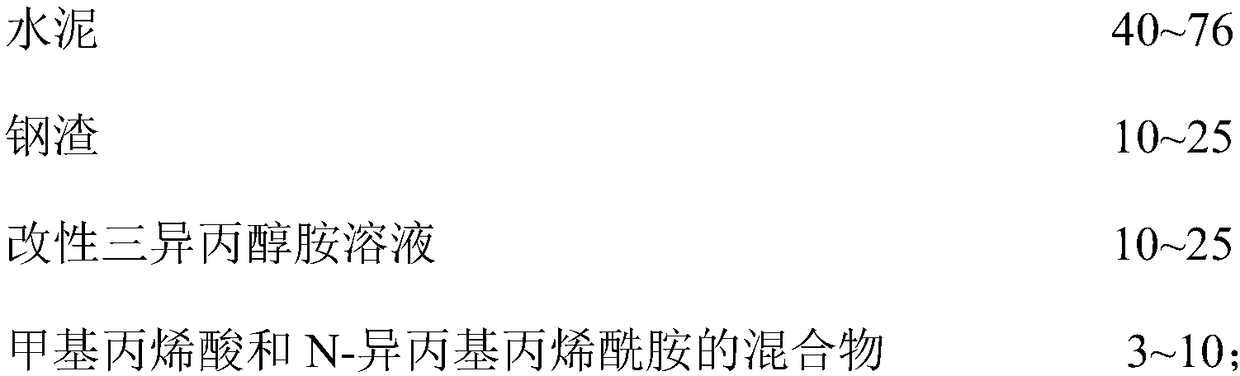

Foundation soil polymeric consolidation agent

The technology of foundation soil and consolidating agent is applied in the field of polymer foundation soil consolidating agent, which can solve the problems of insufficient environmental protection and economy, and achieve the effects of enhancing unconfined compressive strength, stable development of strength, and improving dry shrinkage performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] The preparation method of the present invention is:

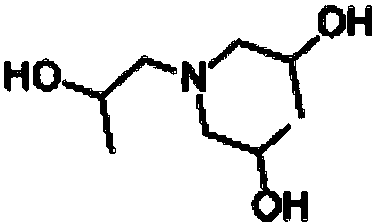

[0030] 1. Prepare the modified triisopropanolamine solution. The weight percentage ratio of each raw material of the modified triisopropanolamine solution is as follows:

[0031] Triisopropanolamine 35~45%

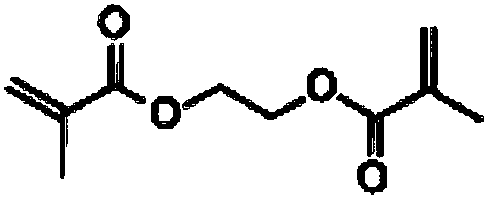

[0032] Diethylene glycol methacrylate 12~20%

[0033] Organic solvent 37~50%

[0034] Further, the organic solvent is styrene, triethanolamine and alcohol.

[0035] The step of preparing the modified triisopropanolamine solution is a, heating the homogenizer reactor to 50~70℃, and slowing down the triisopropanolamine with 35~45% by weight and the organic solution with purity above 60%. Add it and wait for it to heat up; b. Slowly add 12-20% by weight of ethylene glycol dimethacrylate into the homogenizer reactor of triisopropanolamine, stir for 5-20min, and prepare the modified Triisopropanolamine solution.

[0036] 2. Preparation of a mixture of methacrylic acid and N-isopropylacrylamide:

[0037] Mix methacrylic acid and ...

Embodiment 1

[0057] Prepare the polymer foundation soil consolidation agent of the present invention according to the ratio shown in Table 1:

[0058] Table 1 Consolidating agent mixing ratio A

[0059]

[0060] Then follow Table 2 to design the mix ratio of consolidated foundation soil.

[0061] Table 2 Consolidated soil mix ratio 1#

[0062] Serial number

Embodiment 2

[0064] Prepare the polymer foundation soil consolidation agent of the present invention according to the ratio shown in Table 3:

[0065] Table 3 Consolidating agent mixing ratio B

[0066]

[0067] Then according to the contents of Table 2 to design the mix ratio of the consolidated foundation soil.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com