Ammonium sulfate refining device

A refining device and ammonium sulfate technology, applied in the direction of ammonium sulfate, etc., can solve the problems of poor practicability, waste of ammonium sulfate, poor refining effect of ammonium sulfate, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

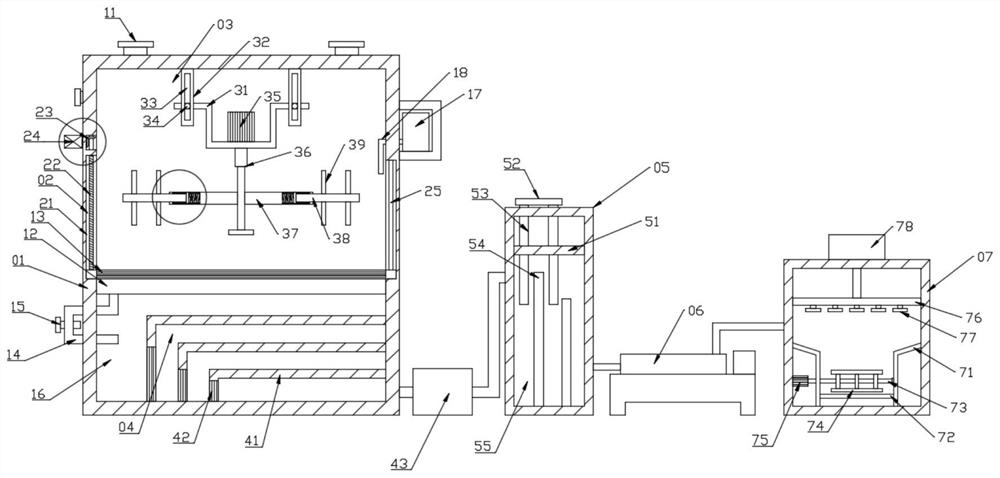

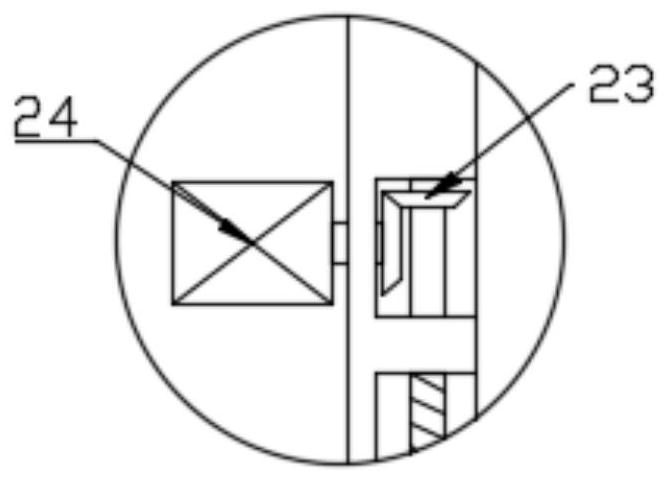

[0025] see Figure 1~3 , in an embodiment of the present invention, a refining device for ammonium sulfate includes a mixing box 01, and the mixing box 01 is provided with a feed port 11 for crude ammonium sulfate to enter, and the crude ammonium sulfate enters the mixing box 01 through the feed port 11 Inside, the first fixed plate 12 is fixed in the mixing box 01, and the first filter screen 13 is movably connected to the top of the first fixed plate 12 through the drive assembly 02, and the filtering effect can be played through the first filter screen 13. When the first filter When the net 13 moves in the vertical direction, the impurities can also be brought into the top to facilitate the removal of the impurities. The stirring assembly 03 is arranged above the first filter screen 13, and the stirring assembly 03 can play the role of stirring, so that the crude sulfuric acid Ammonium is quickly mixed with water, which has very good practicability; in addition, the first f...

Embodiment 2

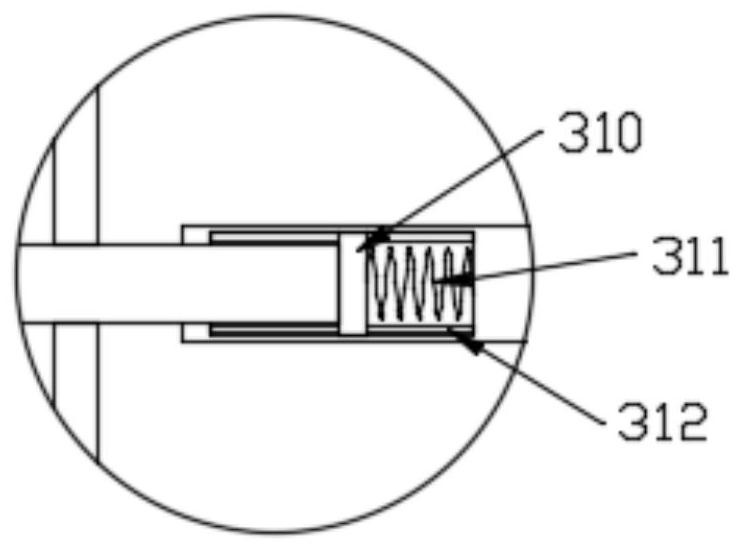

[0034] One end of the second stirring shaft 38 is fixed with a connecting block 310, and the connecting block 310 is slidably connected with the second guide rod 312 on the second stirring shaft 38, thereby improving the stability and safety during the moving process. 310 is connected to the first agitating shaft 37 through a spring 311, thereby facilitating adjustment of the position of the second agitating shaft 38, which has very good practicability.

[0035] The working principle of the present invention is: add crude ammonium sulfate to the inside of the mixing box 01 through the feed port 11, stir through the stirring component 03, and drive the first filter screen 13 to move in the vertical direction through the driving component 02 during the stirring process , and then filtered, and then enter the filter cavity 16 through the discharge pipe 14, enter the ammonium removal tank 05 to remove ammonium after passing through the multiple filtration of the filter assembly 04,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com