Combined multifunctional phosphate ester fire-resistant oil purification equipment

A purification equipment and multi-functional technology, applied in chemical instruments and methods, liquid degassing, separation methods, etc., can solve problems such as single function, tripping of generator sets, shutdown of generator sets, etc., achieve high acid removal capacity, and increase resistivity , strong versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

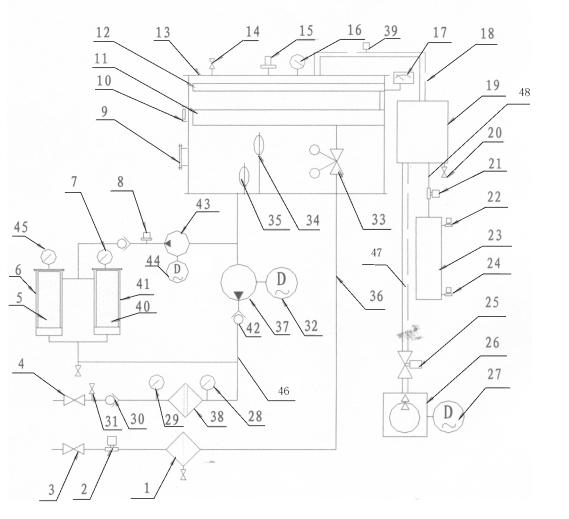

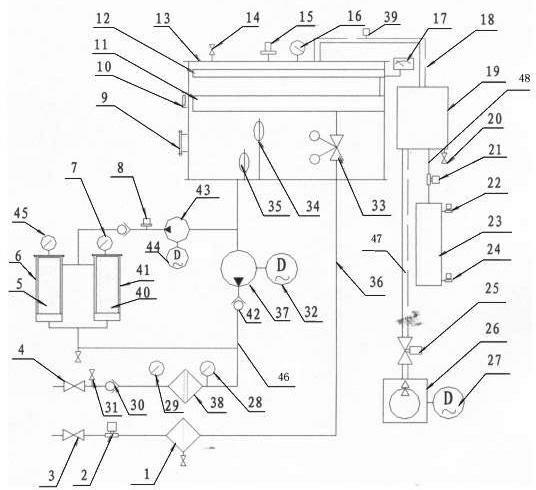

[0009] in figure 1 Among them, the present invention provides a combined multifunctional phosphate-resistant fuel oil purification equipment, which is provided with a vacuum tank 13, one side of the vacuum tank 13 is provided with a photoelectric switch 10 and a window 9, and the other side of the vacuum tank 13 is provided There is a temperature controller 17, on the top of the vacuum tank 13, there is an inflation valve 14, solenoid valve Ⅱ15 and vacuum gauge Ⅱ16, in the upper part of the inner cavity of the vacuum tank 13 is provided with a deluge 12, in the middle of the inner cavity of the vacuum tank 13 The heater 11, the heater 11 and the deluge 12 are opposite, the high oil level switch 34, the low oil level switch 35 and the oil drift valve 33 are respectively provided at the bottom of the inner cavity of the vacuum tank 13, which are respectively connected to the bottom of the vacuum tank 13 There are an oil inlet pipe 36 and an oil outlet pipe 46. One end of the oil ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com