Structural improvement method for drum brake pad high-precision inner arc grinding machine

A technology for structural improvement and brake pads, which is applied in the direction of grinding machines, manufacturing tools, grinding/polishing equipment, etc., can solve the problem of bed wall thickness and rib thickness, lack of brake pad grinding machine dynamics analysis, lack of drum type Issues such as building a solid model of the inner arc grinding machine for brake pads

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0077] The technical scheme of the structure improvement method of the high-precision internal arc grinding machine for drum brake pads provided by the present invention will be further described below in conjunction with the accompanying drawings, so that those skilled in the art can better understand the present invention and implement it.

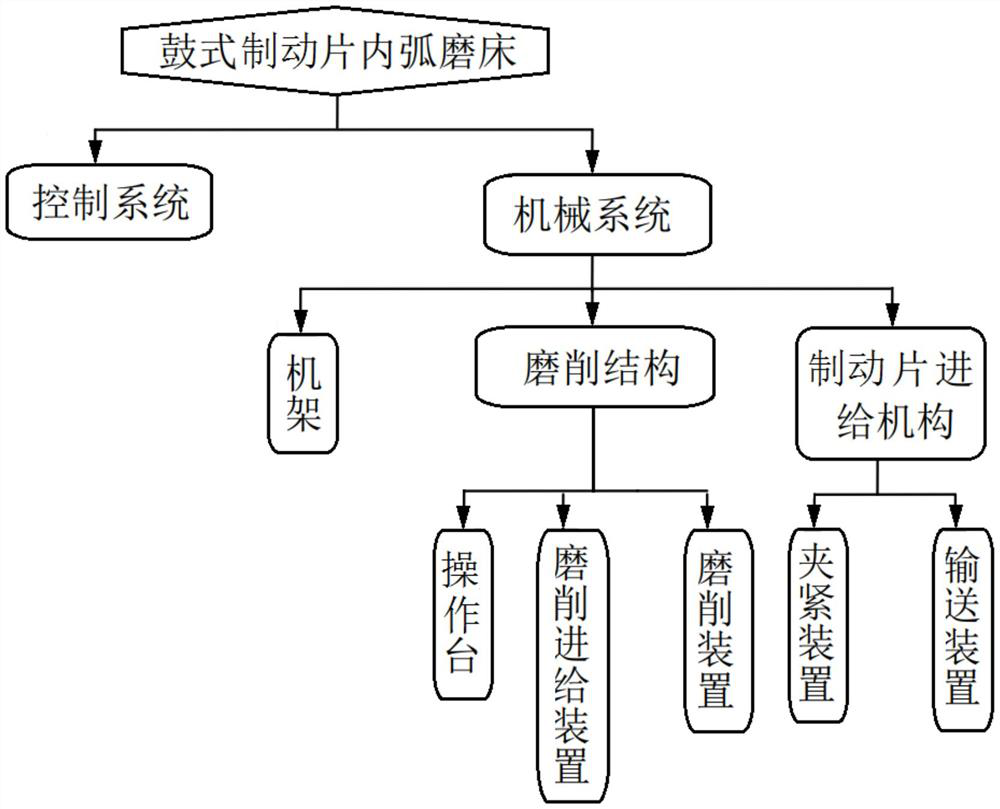

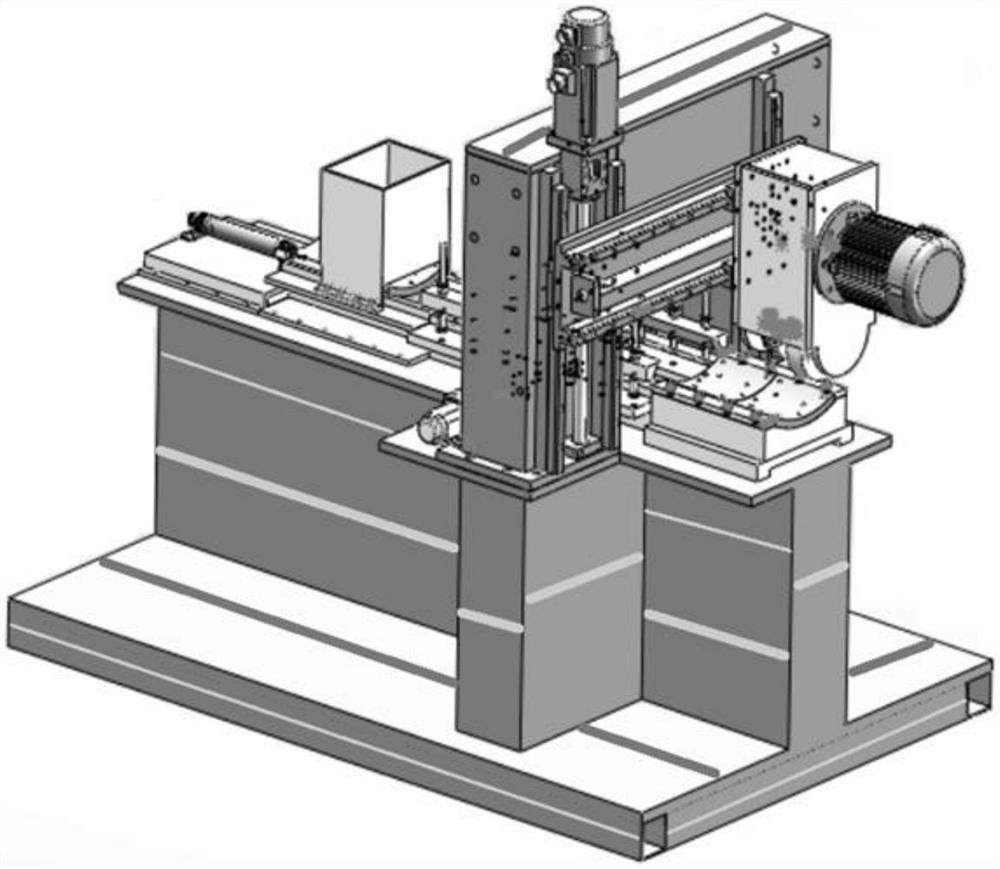

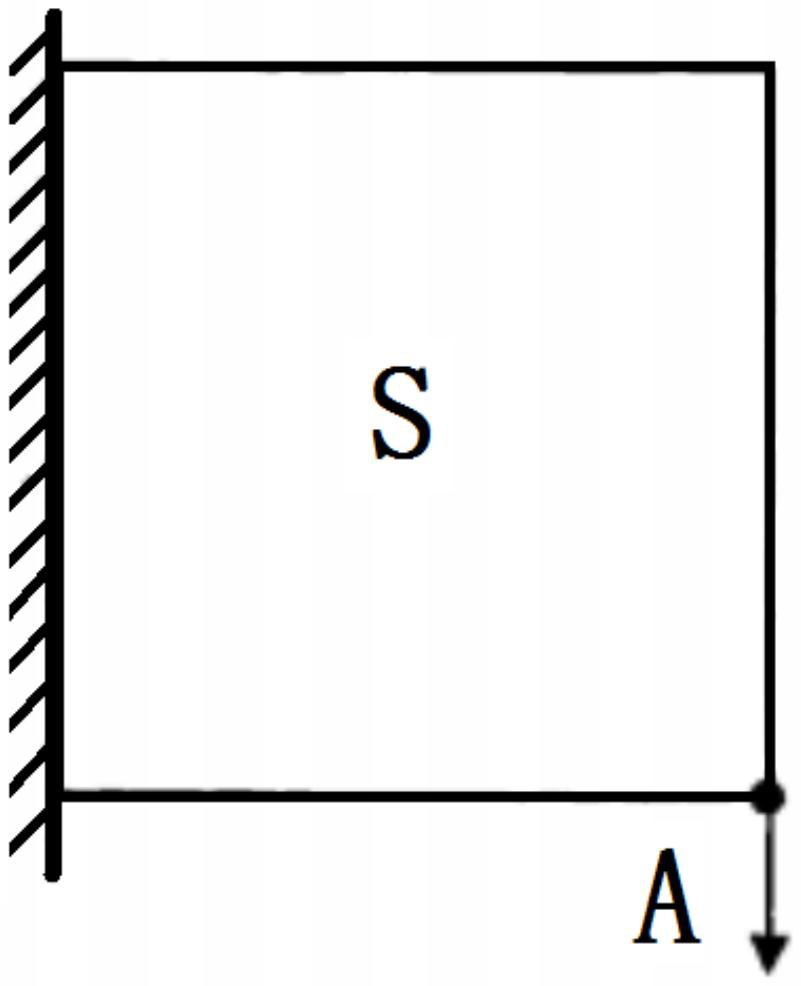

[0078] The method for improving the structure of the high-precision internal arc grinding machine for drum brake pads of the present invention first establishes a physical model of the internal arc grinder for drum type brake pads, such as figure 1 As shown, then the static analysis of the inner arc grinder is realized based on the finite element analysis method, and then the structural dynamic characteristics of the inner arc grinder for the drum brake pad are analyzed, and finally the structure of the inner arc grinder for the drum brake pad is improved;

[0079] The first is to establish the solid model of the inner arc grinding machin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Maximum deformation | aaaaa | aaaaa |

| Maximum stress | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com