LAP laser engraving process

A technology of laser radium engraving and laser laser, which is applied in the direction of laser welding equipment, manufacturing tools, metal processing equipment, etc., can solve the problems of line outline corrosion, large residual amount, and influence on coating, so as to achieve clear outline, improve product quality, reduce The effect of wasting resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Please refer to Figure 1 to Figure 4 , Embodiment 1 of the present invention is: a kind of LAP laser engraving craft, comprises the following steps,

[0045] S1. Obtain a plastic substrate 1;

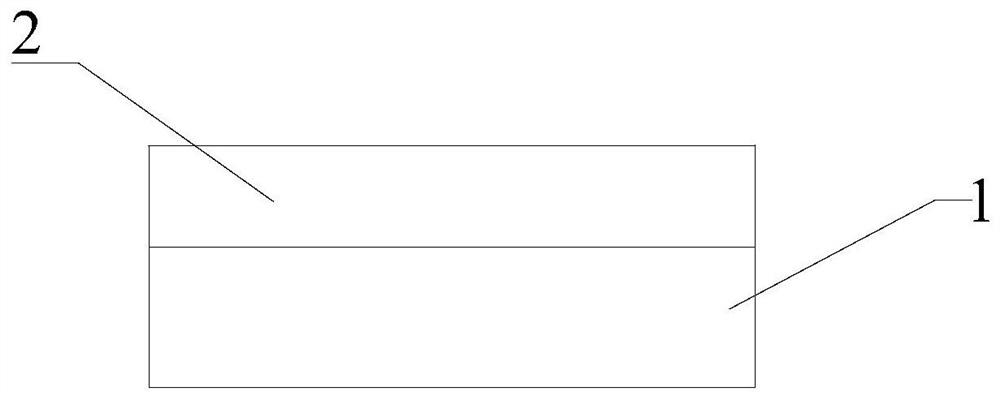

[0046] S2, coating an oxide film 2 on the surface of the substrate 1;

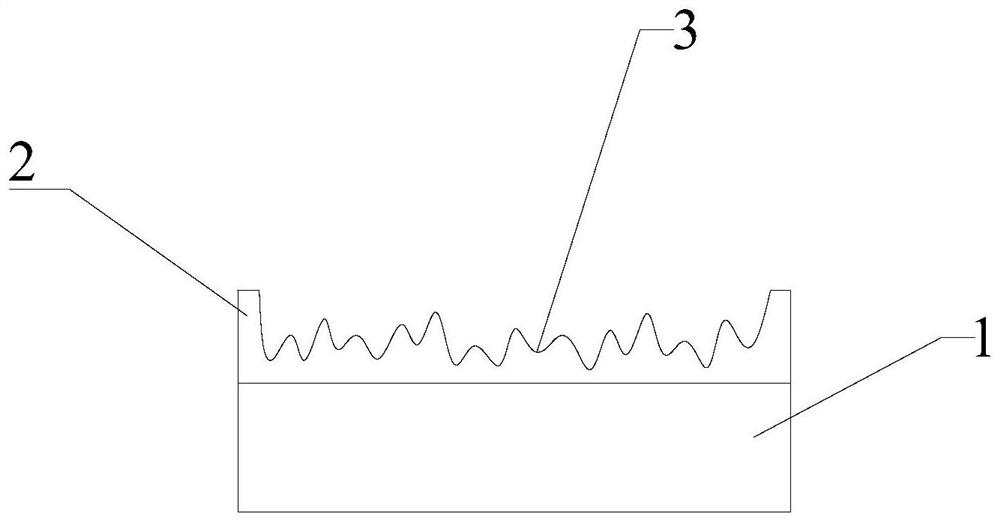

[0047] S3, making circuit wiring groove 3 on the surface of substrate 1 coated with oxide film 2 by laser;

[0048] S4 , chemically plating the metal layer 4 inside the circuit wiring groove 3 on the substrate 1 .

[0049] Such as figure 1 As shown, in step S1, the substrate 1 is injection molded according to the shape of the product in actual production, or purchased directly from a supplier.

[0050] Further, before step S2, it also includes step S11, cleaning and destaticizing the surface of the substrate 1; step S12, grinding and sandblasting the surface of the substrate 1; step S13, spraying a primer on the substrate 1, and baking Primer to primer set. The purpose of step S11 is to remove oil stai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com