Preparation method of Janus particles and application of Janus particles in cyclohexene hydration process

A particle and peracid technology, which is used in the preparation of Janus particles and the application field in the hydration process of cyclohexene, can solve the problems affecting the conversion rate of cyclohexene, the imbalance of the reaction phase interface, etc., and improve the conversion rate of cyclohexene. , the effect of improving the conversion rate of cyclohexene and the selectivity of ideal cyclohexene

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

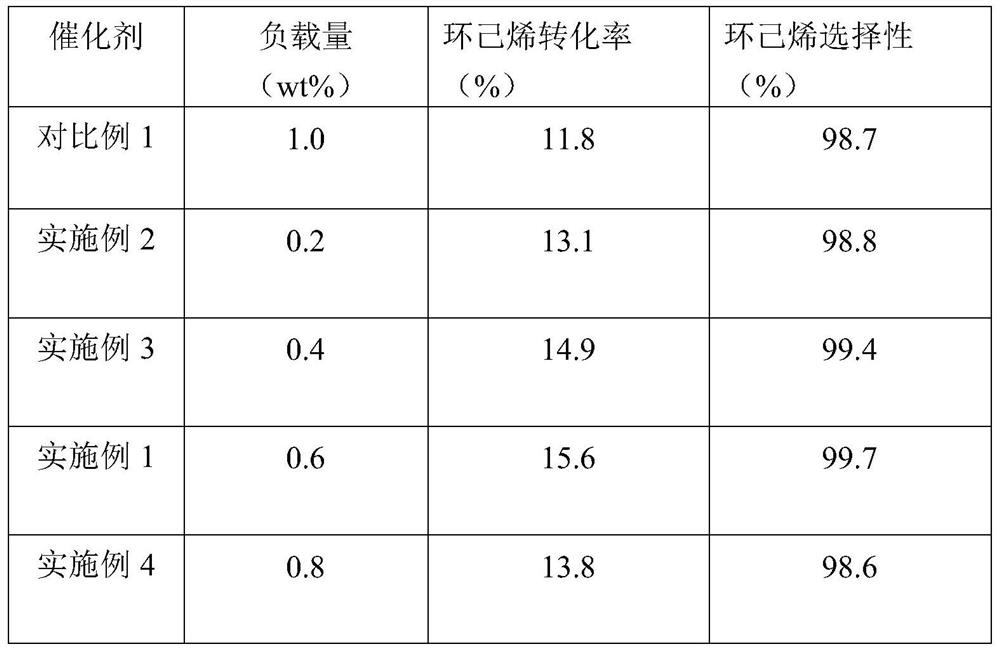

Embodiment 1

[0041] A method for preparing Janus particles includes the following steps:

[0042] (1) Accurately measure 10g of HZSM-5 molecular sieve, use phosphotungstic acid solution for equal volume impregnation; determine the saturated water absorption rate of HZSM-5 molecular sieve is 0.625mL / g, weigh out 0.06g phosphotungstic acid, and configure it according to the saturated water absorption rate The phosphotungstic acid solution (6.25mL) that can make HZSM-5 is immersed in equal volume; stir the HZSM-5 molecular sieve, add the configured phosphotungstic acid solution to it while stirring, continue to stir until the stirring is uniform; Put the HZSM-5 molecular sieve in an oven and dry at 120°C for 12h; after drying, put it into a muffle furnace and roast at 400°C for 4h to obtain a phosphotungstic acid modified HZSM-5 molecular sieve. The phosphotungstic acid loading is HZSM-5 The mass of the molecular sieve is 0.6% by weight.

[0043] (2) The phosphotungstic acid modified HZSM-5 molec...

Embodiment 2

[0048] The difference from embodiment 1 is: in step (1), 0.02 g of phosphotungstic acid is weighed; other technical features are the same as embodiment 1. The load of phosphotungstic acid is 0.2wt% based on the mass of HZSM-5 molecular sieve.

Embodiment 3

[0050] The difference from embodiment 1 is: in step (1), 0.04 g of phosphotungstic acid is weighed; other technical features are the same as in embodiment 1. The load of phosphotungstic acid is 0.4wt% based on the mass of HZSM-5 molecular sieve.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com