Straw smashing returning and plastic film residue recycling bundling machine

A straw pulverizer and residual film recycling technology, which is applied to collectors, harvesters, agricultural machinery and implements, etc., can solve the problems of large manpower or mechanical power consumption, high manpower consumption, and high difficulty in recycling plastic film residues.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

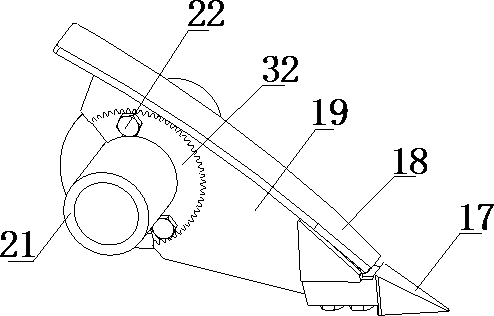

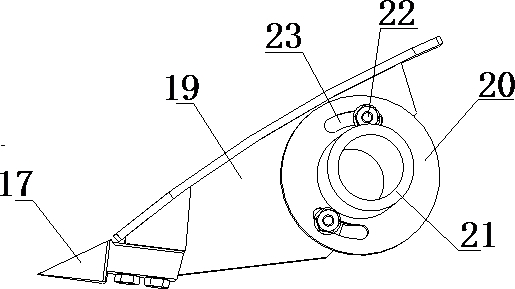

[0020] In order to have a clearer understanding of the technical features, objectives and effects of the present invention, specific embodiments of the present invention will now be described with reference to the accompanying drawings. The same reference numerals in each figure represent the same components. In order to make the drawings concise, the drawings only schematically show the parts related to the invention, and they do not represent the actual structure of the product.

[0021] Such as figure 1 , 2 , 3, 4, the present invention is a straw crushing and returning to the field and residual film recovery and baler, including a straw crusher 4, a film forming machine 8 and a baler 10 on the frame 1, and an output shaft on the tractor Connected to the first gearbox 3, the second gearbox 9 and the third gearbox 11 respectively. The front end of the straw crusher 4 is provided with a traction frame 2 connected to the tractor's tie rod. The output shaft on the tractor is connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com