Wafer Fragmentation Method and Its Application

A wafer and wafer technology, applied in the wafer splitting method and its application field, can solve the problems of long sample preparation time, expensive equipment, complicated equipment, etc., to simplify the splitting process, increase accuracy and stability, and shorten the splitting time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

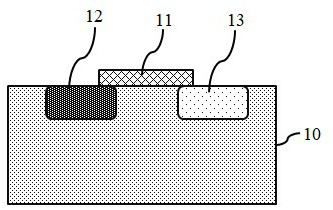

[0042] In order to make the purpose, advantages and features of the present invention clearer, the wafer splitting method and the wafer failure analysis method proposed by the present invention will be further described in detail below. It should be noted that, the accompanying drawings are all in a very simplified form and in inaccurate scales, and are only used to facilitate and clearly assist the purpose of explaining the embodiments of the present invention.

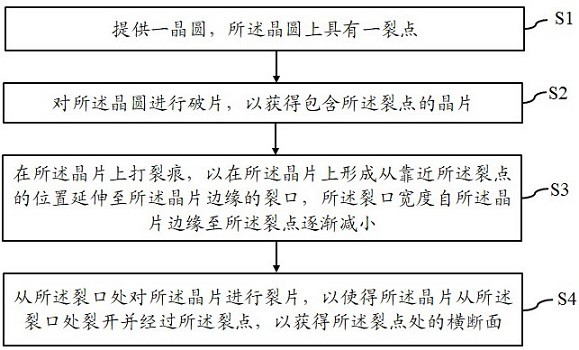

[0043] An embodiment of the present invention provides a wafer splitting method, refer to image 3 , image 3 It is a flowchart of a wafer splitting method according to an embodiment of the present invention, and the wafer splitting method includes:

[0044] Step S1, providing a wafer with a crack on the wafer;

[0045] Step S2, fragmenting the wafer to obtain a wafer containing the crack;

[0046] Step S3, making a crack on the wafer to form a crack on the wafer extending from a position close to the crack point ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com