Measurement system and method for obtaining natural frequency of reducer cycloid wheel under different working conditions

A technology of natural frequency and measurement system, applied in the field of measurement system of the natural frequency of the cycloidal wheel of the reducer, can solve the problems of unstable position, difficulty, shaking, etc., and achieve the effects of improving efficiency, high measurement accuracy and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

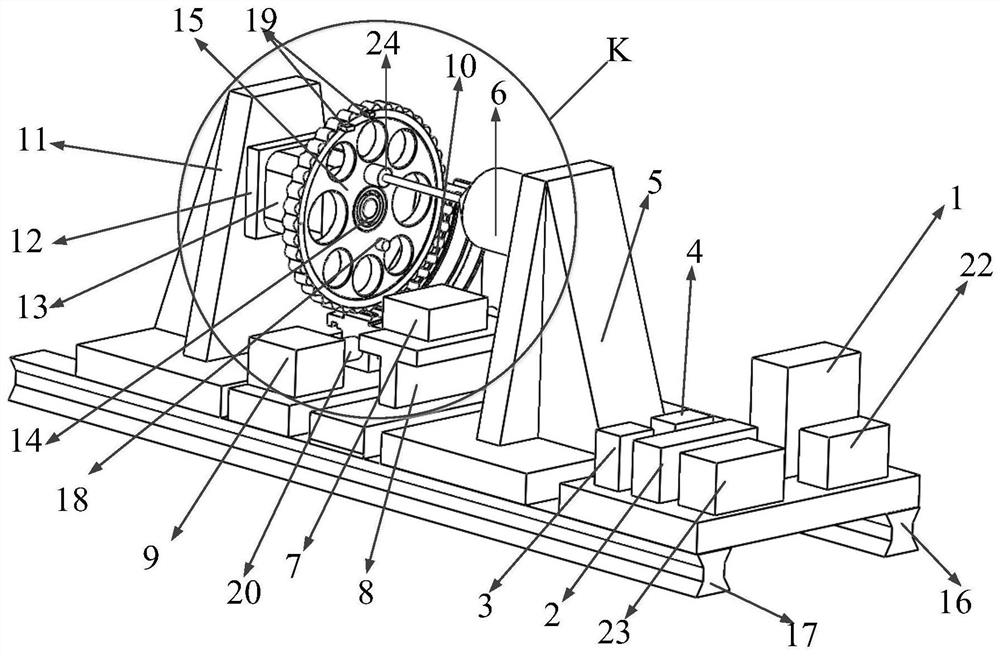

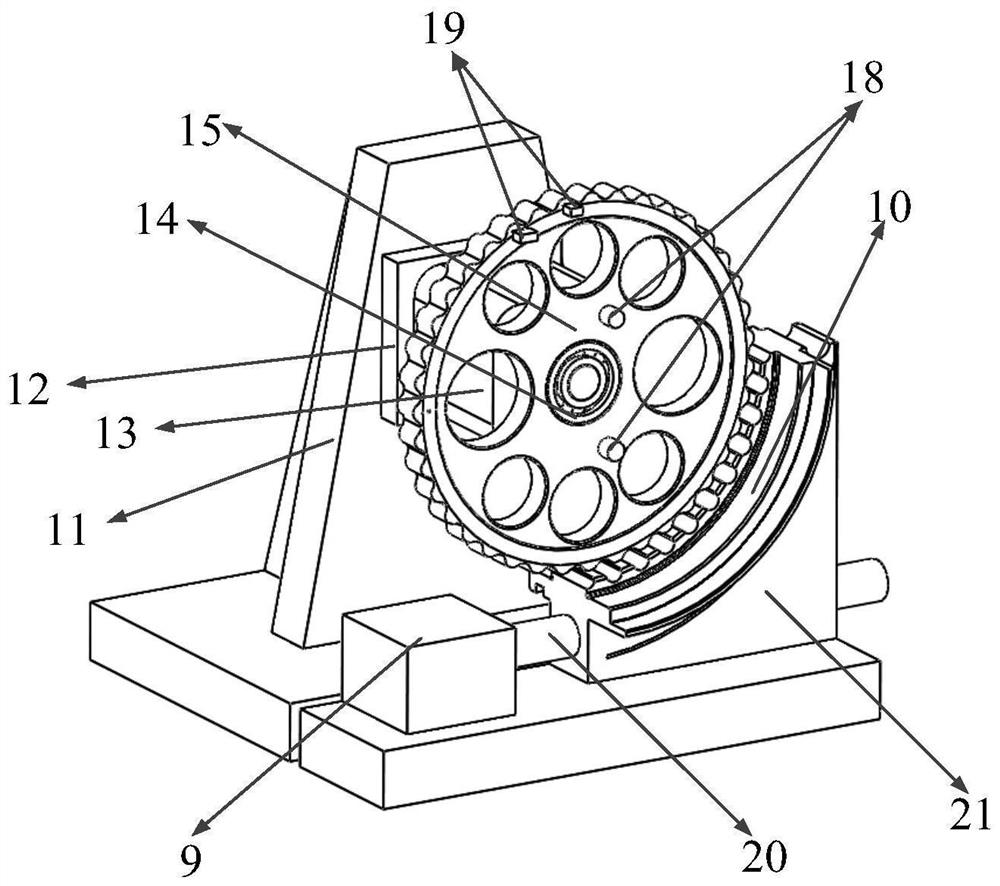

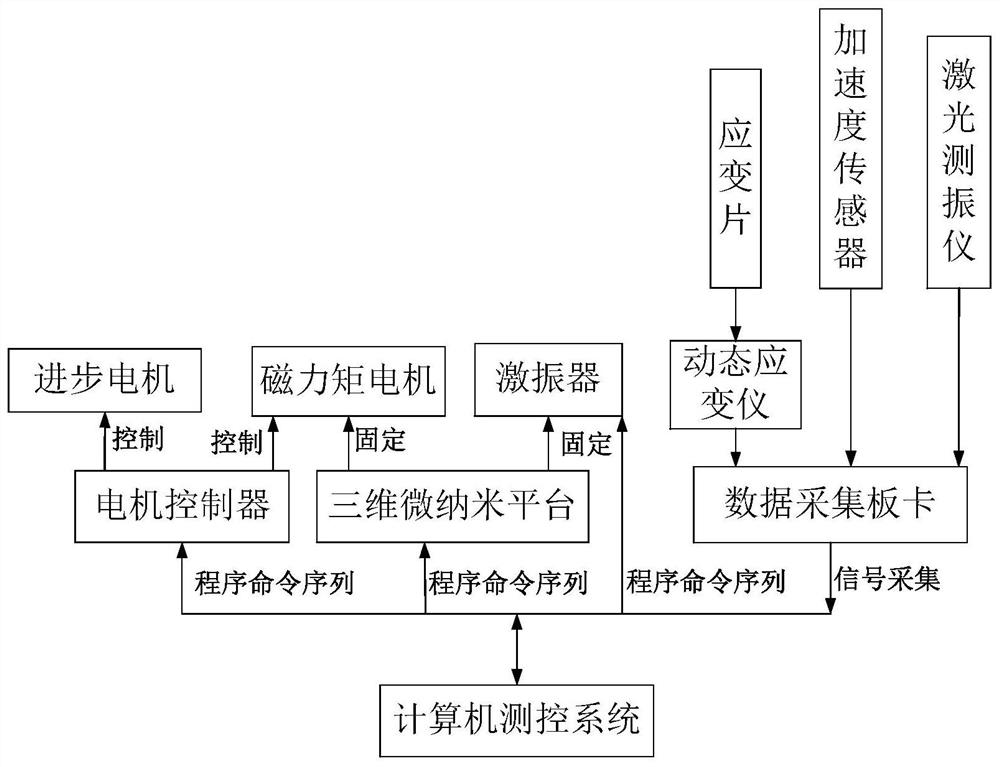

[0042] refer to Figure 1 ~ Figure 3 As shown, the measurement system for obtaining the natural frequency of the cycloid wheel of the reducer under different working conditions in an embodiment provided by the present invention includes a fine-tuning displacement mechanism, a magnetic torque motor power device, a pin gear housing 10 for detection, an acceleration sensor 18, Strain gauge sensor, vibrator 6, vibrometer, voltage output DA module 22, force sensor 24, high-voltage power amplifier 23 and measurement and control system, magnetic torque motor power device and vibrator 6 are relatively arranged on the fine-tuning displacement mechanism, and the magnetic force The output end of the torque motor power unit is used to connect with the cycloidal wheel 15 to be detected, and the magnetic moment motor power unit drives the cycloidal wheel 15 to be d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com