Biological manufacturing method of bionic vascular smooth muscle layer

A vascular smooth muscle, bio-manufacturing technology, applied in the field of 3D printing and biology, can solve problems such as difficulty in mass production, unadjustable thickness of blood vessels, and complex manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

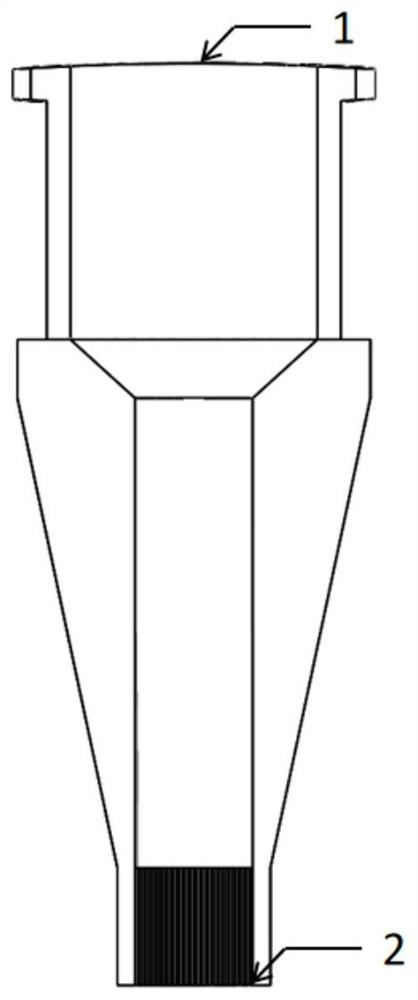

[0034] Step 1, if figure 1 As shown, design and manufacture special-shaped needles. Using 3D computer-aided design software (SolidWorks) to design the model of MM3D printing needle. The model was converted into a stereolithography file and printed using a stereolithography 3D printer (nanoArch P140) to obtain a shaped needle; the shaped needle was rinsed with isopropanol, and then the channel was rinsed with a syringe. Then, it is air-dried and stored in the dark until ready to use.

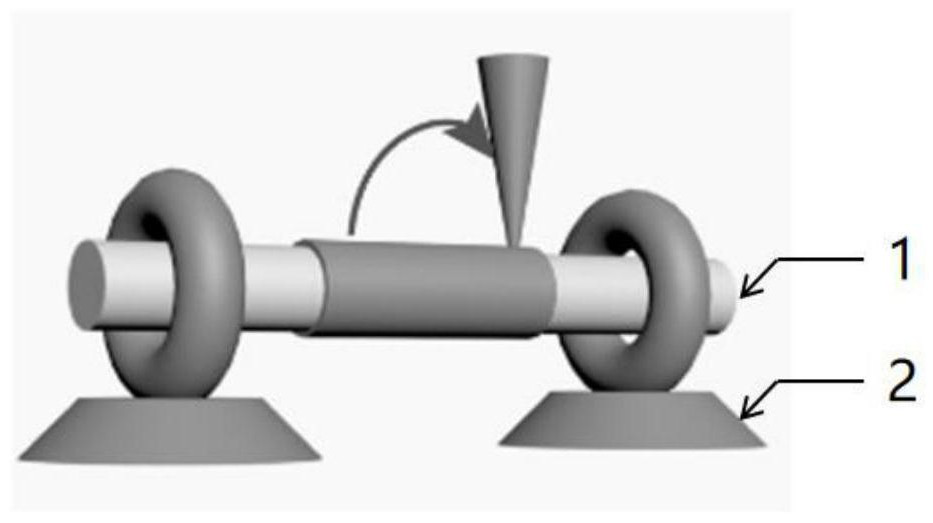

[0035] Step 2, if image 3 As shown, on the 3D direct-writing printing equipment, a printing platform for the outer wall of blood vessels is built. First build a pneumatic three-axis printing platform, which can move in the three directions of X, Y and Z, and then install the rotating shaft base on the three-axis platform, and the rotating shaft includes a rotatable U-axis.

[0036] Step 3, configure the printing paste PDMS. PDMS is SE1700 (Dow Corning), and the ratio of substrate to crossli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com