Method and system for manufacturing aluminum alloy part

A technology for manufacturing equipment and manufacturing methods, which is applied in the field of manufacturing aluminum alloy parts and manufacturing equipment, and can solve problems such as fracture of extruded materials, slow temperature drop, poor thermal shrinkage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

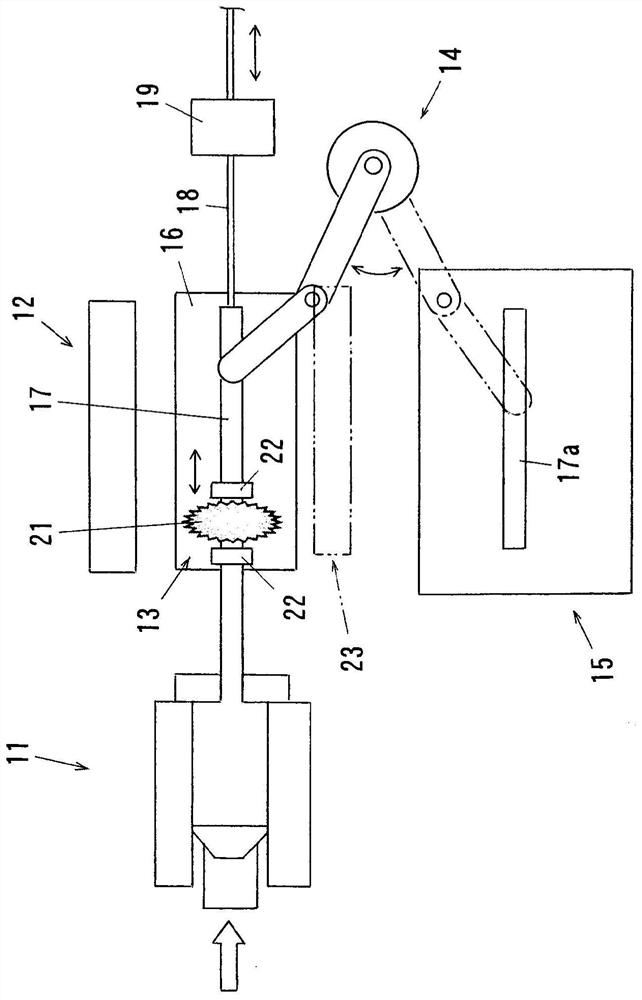

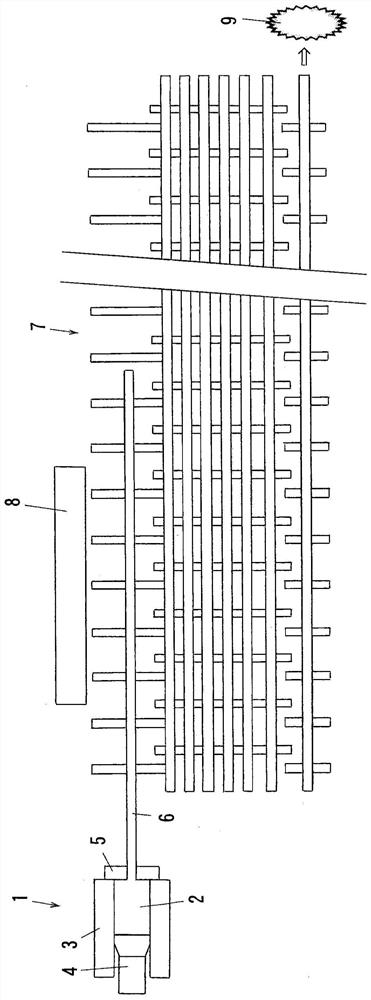

[0049] Below, refer to figure 1 The schematic diagram of the figure shows an example of the manufacturing method and manufacturing equipment of the aluminum alloy part of this invention.

[0050] figure 1 The shown manufacturing facility includes: an extruder device 11 ; a cooling device 12 and a cutting device 13 disposed on the output side of the extruder device 11 ;

[0051] The extruder device 11 is not changed from the conventional example, and the heat treatment type aluminum alloy is subjected to hot extrusion processing. Examples of heat-treatable aluminum alloys include 2000-series, 6000-series, and 7000-series aluminum alloys specified by JIS (Japanese Industrial Standards) or registered by AA (Aluminum Association).

[0052] The cooling device 12 includes at least one of a fan air cooling device or a water cooling device, and forcibly cools and quenches the extruded material 17 extruded from the die of the extruder device 11 and moved forward on the table 16 . ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com