Machine tool cutting fluid rapid preparation device for machine manufacturing

A technology for machine manufacturing and cutting fluid, which is applied in the field of rapid preparation device for machine tool cutting fluid for machine manufacturing, and can solve the problems of lowering the preparation quality and poor preparation effect of cutting fluid, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

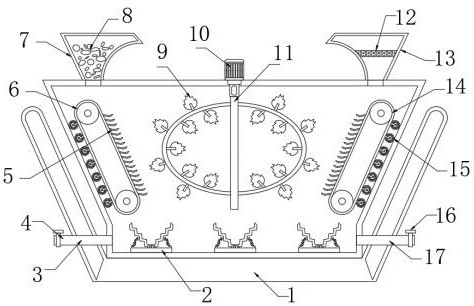

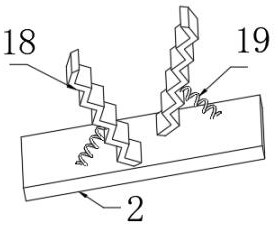

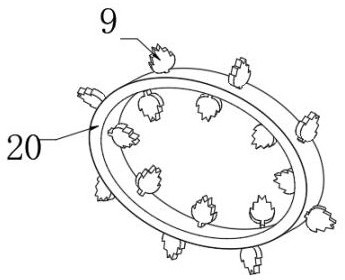

[0030] refer to Figure 1-5 , a machine tool cutting fluid rapid preparation device for mechanical manufacturing, comprising a preparation box 1, the top outer wall of the preparation box 1 is fixed with a feed box 7 with low water hardness and a feed box 13 with high water hardness by screws, and the water hardness is relatively high The inner walls of the low feeding box 7 and the higher water hardness feeding box 13 are respectively provided with natural coral sand 8 and a cation exchange resin layer 12, and the both sides of the inner wall of the preparation box 1 are respectively provided with a conveyor belt 6 and a second conveyor belt 14, and the conveyor belt 6 and one side outer wall of the second conveyor belt 14 are provided with equidistantly distributed scrapers 5, the scraper 5 is a spatula-shaped structure, and one side outer wall of the conveyor belt 6 and the second conveyor belt 14 is provided with equidistantly distributed fixing plates 21, and the outer wa...

Embodiment 2

[0037] refer to Figure 6 , a machine tool cutting fluid rapid preparation device for mechanical manufacturing. Compared with Embodiment 1, this embodiment also includes a liquid level sensor 28 fixed to the inner wall of the bottom of the preparation box 1 by screws, and a display screen is provided on one side of the outer wall of the preparation box 1. 29, and the signal input end of the display screen 29 is connected to the processor through the signal line, and the signal output end of the liquid level sensor 28 is connected with the signal input end of the processor through the signal line.

[0038]Connect the equipment to the power supply, and select different feeding boxes for feeding according to the hardness value of the water, which can increase or decrease the hardness of the water to a certain extent, and improve the preparation quality of the cutting fluid. Open the conveyor belt 6 and the second conveyor belt 14, and the conveyor belt 6 and the second conveyer b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com