An auxiliary stamping forming method with partial modification of welding technology

A technology of stamping forming and partial modification, which is applied in the field of stamping forming, can solve the problems of limited industrial application range, poor hardness adjustability, and low structural adaptability, and achieve the effects of increased metal hardness, high processing efficiency, and improved formability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

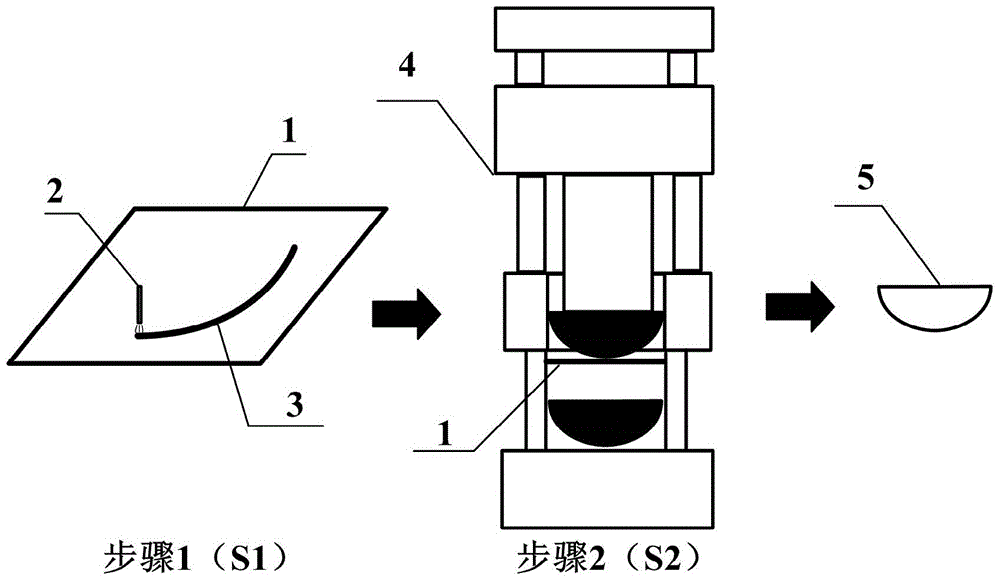

[0030] Adopt the present invention to prepare high-strength steel structural parts, plate 1 thickness 1mm, because the hardness of high-strength steel plate is relatively high, so it is difficult to shape the deformed corners, so the method of arc welding is used to soften the part and then stamping. The preparation method includes the following steps:

[0031] S1. Fix the plate 1 to be processed with a fixture, input the travel path program in the traveling mechanism of the welding torch 2, and move the welding torch 2 to the starting point of welding; use DC tungsten argon arc welding for welding, and set the welding parameters as follows : Welding current 60A, welding voltage 10V, tungsten electrode height 2mm, welding gun perpendicular to the surface of plate 1; then use arc welding to carry out surfacing welding on the surface of plate 1 along the predetermined track, so as to obtain weld 3 with hardness lower than plate 1, after welding is completed Release the clamp.

...

Embodiment 2

[0034] Adopt the present invention to prepare aluminum alloy structural parts in annealed state, the thickness of the plate 1 is 0.5mm, because the hardness of the aluminum alloy plate is low, so the deformed part is easy to rebound, so the method of laser welding is used to make the local hardening and then stamping. The preparation method includes: Follow the steps below:

[0035] S1. Fix the plate 1 to be processed with a fixture, input the travel path program in the traveling mechanism of the welding torch 2, and move the welding torch 2 to the starting point of welding; use the laser method for welding, and set the welding parameters as follows: laser power 1200W, The defocus amount is -1mm, and the laser beam is perpendicular to the surface of the plate 1; then, laser welding is used to carry out surfacing welding on the surface of the plate 1 along the predetermined track, so as to obtain a weld 3 with a hardness higher than that of the plate 1, and release the clamp aft...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com