Method for manufacturing positive electrode active material for secondary battery

A positive active material, secondary battery technology, used in secondary batteries, battery electrodes, positive electrodes, etc., can solve the problems of inability to ensure stability, large specific surface area, low particle strength, etc., achieve excellent stability, improve particle Strength, effect of reducing specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0020] The method for preparing a positive electrode active material for a secondary battery of the present invention comprises the steps of: providing a positive electrode active material precursor comprising a core and a shell, wherein the core contains nickel (Ni), cobalt (Co) and manganese (Mn ), and the shell portion contains cobalt (Co) and surrounds the core portion; formed by mixing the cathode active material precursor with a lithium raw material to obtain a mixture and firing the mixture at a temperature of 970° C. or higher A lithium composite transition metal oxide in the form of single particles.

[0021] The method of preparing the cathode active material will be described step by step in detail.

[0022] First, there is provided a positive electrode active material precursor including a core part and a shell part, wherein the core part contains nickel (Ni), cobalt (Co) and manganese (Mn), and the shell part contains cobalt (Co) and surrounds the Describe the nu...

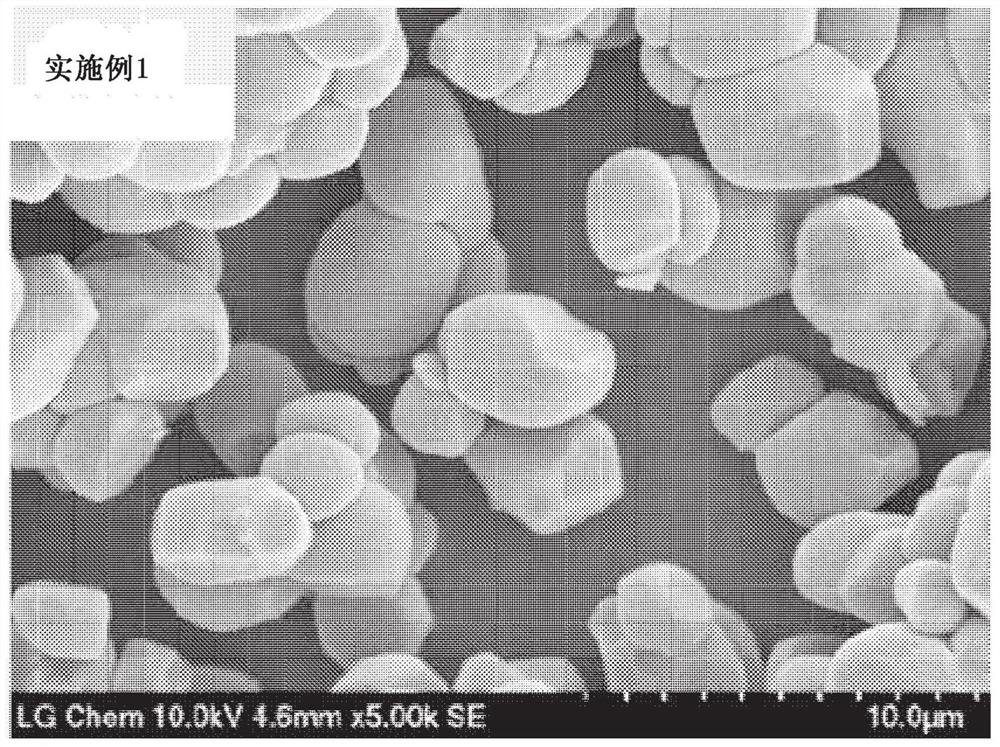

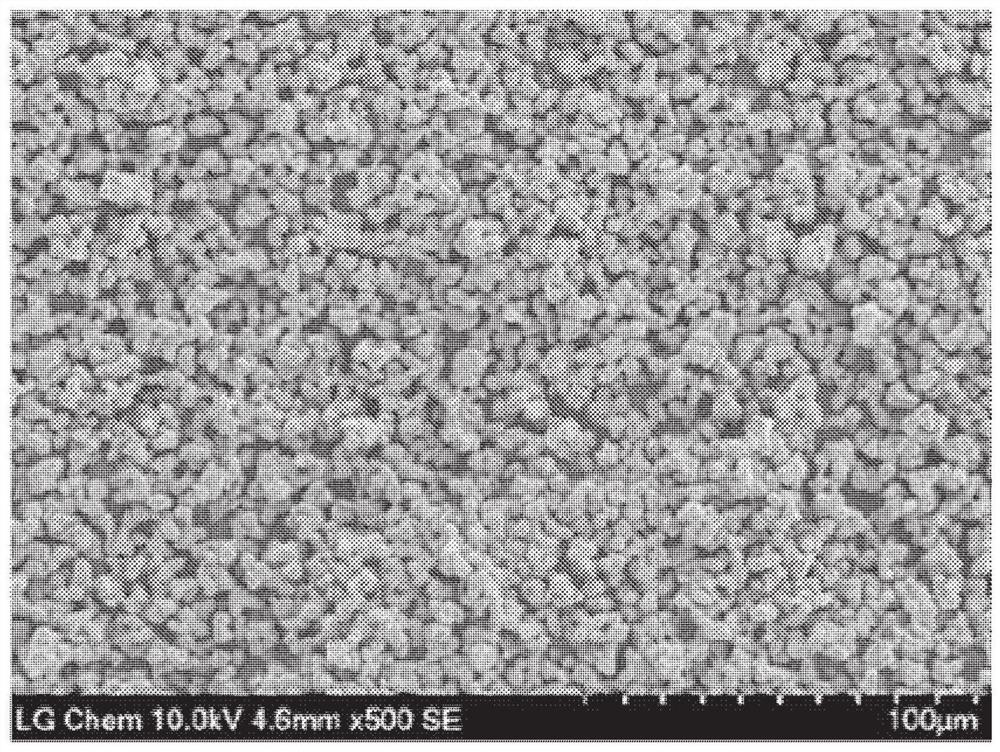

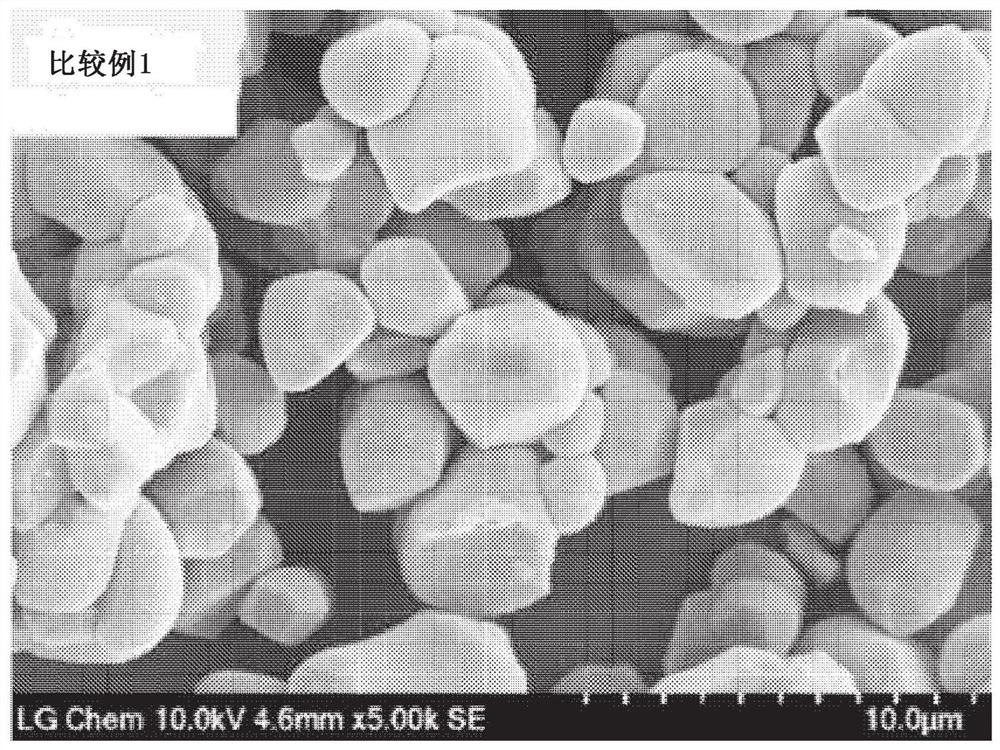

Embodiment 1

[0087] In a batch 40L reactor set at 50°C, NiSO 4 、CoSO 4 and MnSO 4 Nickel:cobalt:manganese was mixed in water in such an amount that the molar ratio of nickel:cobalt:manganese was 57:20:23 to prepare a first transition metal solution having a concentration of 2.4M.

[0088] Add 13 liters of deionized water to the co-precipitation reactor (capacity: 40 L), and purge nitrogen gas into the reactor at a rate of 25 liters / min to remove dissolved oxygen in the water and create a non-oxidizing atmosphere in the reactor. atmosphere. Thereafter, 83 g of an aqueous NaOH solution having a concentration of 25% was added thereto, and the mixture was stirred at a temperature of 50° C. and a stirring speed of 700 rpm so as to maintain a pH of 11.5.

[0089] Afterwards, the first transition metal solution was input separately at a rate of 1.9 L / hour, and NaOH aqueous solution, NH 4 An aqueous OH solution was added thereto, and at the same time, a co-precipitation reaction was performed ...

Embodiment 2

[0094] The lithium composite transition metal oxide prepared in the same manner as in Example 1 was mixed with Al 2 o 3 mix. The mixed mixture was heat-treated at 500° C. for 3 hours in an air atmosphere to prepare a positive electrode active material formed with an Al-coated portion.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com