Manufacturing method of ultra-wideband composite ferrite circulator

A production method and ferrite technology, applied to waveguide devices, electrical components, circuits, etc., can solve problems such as poor consistency, heavy debugging, and electrical performance of tens of microns deep into the gap, so as to avoid heavy debugging.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

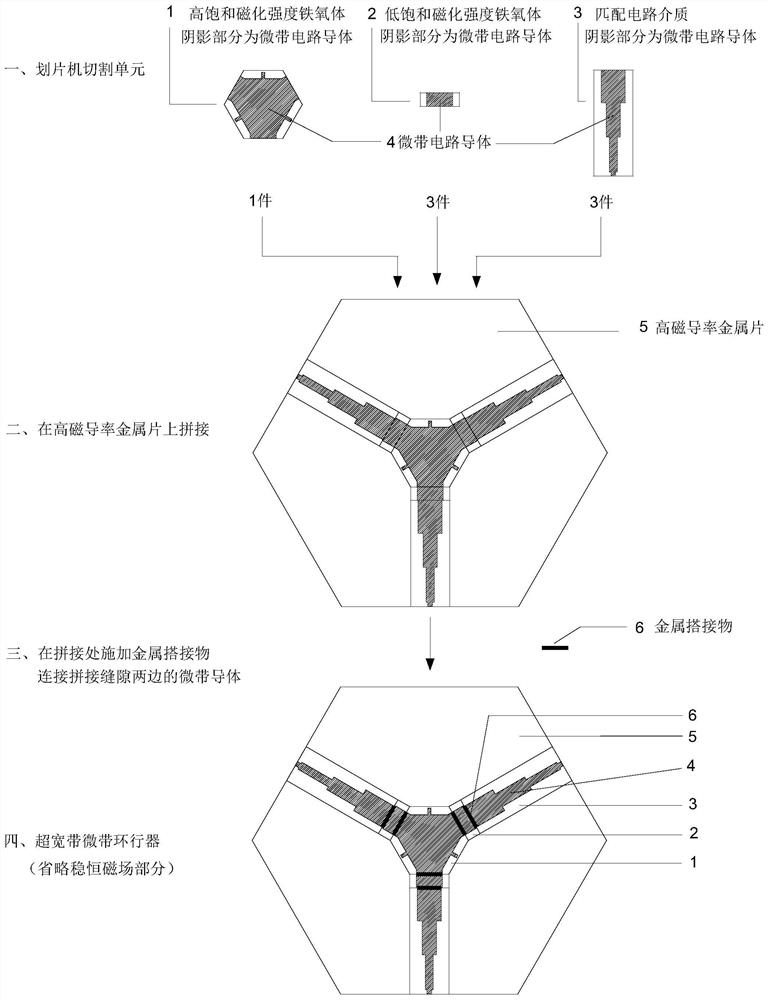

[0030] Such as figure 2 As shown, a spliced ultra-wideband composite ferrite microstrip circulator manufacturing method comprises the following steps:

[0031] 1) Substrate precision polishing: select three substrates to make spliced ultra-broadband composite ferrite microstrip circulators, namely 2500Gauss high saturation magnetization ferrite substrate, 1400Gauss low saturation magnetization ferrite substrate and 99.5% alumina ceramic substrate. The three kinds of substrates are two-inch square sheets, and after rough polishing and precision polishing, substrates with a thickness ranging from 0.4mm to 0.406mm are obtained.

[0032] 2) Fabrication of microstrip circuits: Drill Φ0.4mm positioning holes (for lithography positioning and subsequent back cutting positioning) on the four corners of the above three substrates by laser, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com