LDMOS device and process method

A process method and device technology, applied in semiconductor devices, semiconductor/solid-state device manufacturing, electrical components, etc., can solve problems such as unsatisfactory breakdown voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

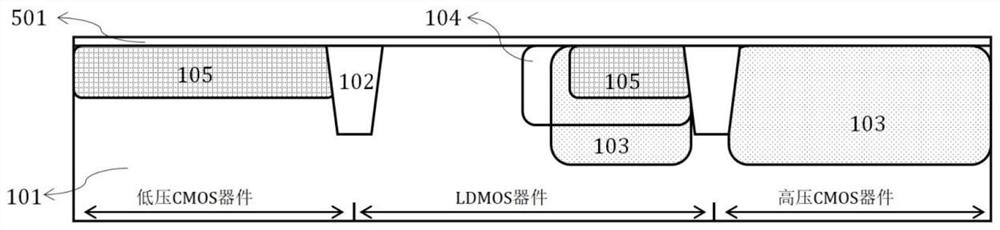

[0040]The technical solution of the present invention will be described in detail below. In the following embodiments, the present invention will take the most common and widely used N-type LDMOS device as an example, that is, the first conductivity type in this embodiment It is defined as P type, and the second conductivity type is defined as N type. In other opposite embodiments, the first conductivity type can be defined as N-type, and the second conductivity type can be defined as P-type, which can be directly replaced, and the present invention will not further elaborate on this.

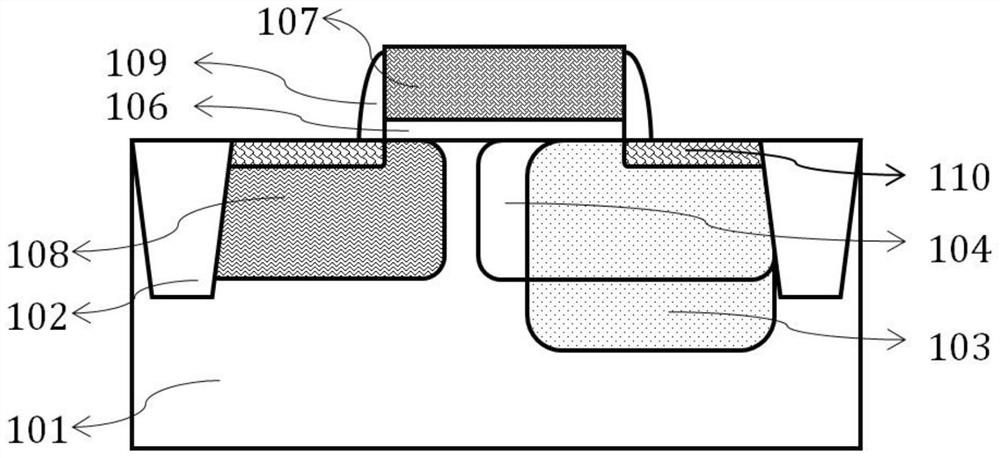

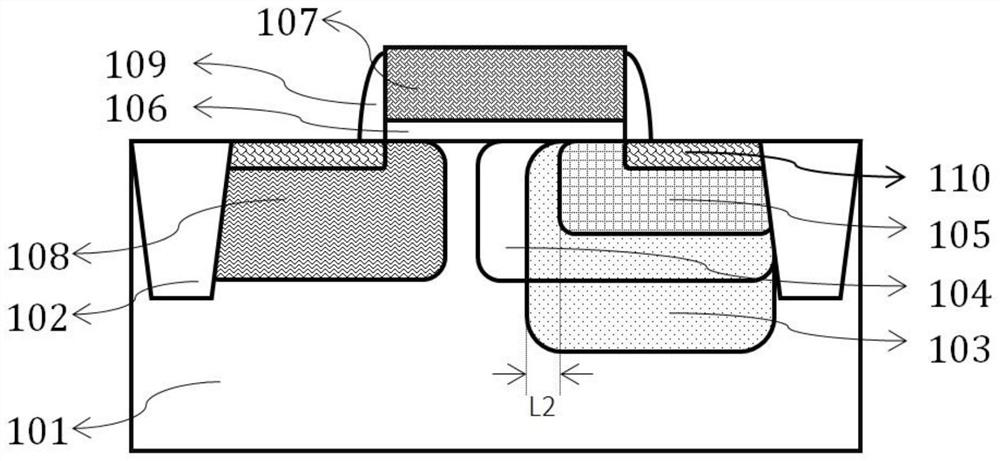

[0041] A kind of LDMOS device described in the present invention, such as figure 2 As shown, there is a P-type body region 108 and an N-type drift region 104 in a P-type substrate or epitaxy 101;

[0042] There is also a polysilicon gate structure on the surface of the P-type substrate, and the polysilicon gate structure includes a gate dielectric layer 106, a polysilicon gate 107, and gate s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com