Aluminum alloy automobile exhaust pipe and preparation method thereof

A technology for automobile exhaust and aluminum alloys, which can be used in exhaust devices, mechanical equipment, machines/engines, etc., and can solve problems such as poor bending resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

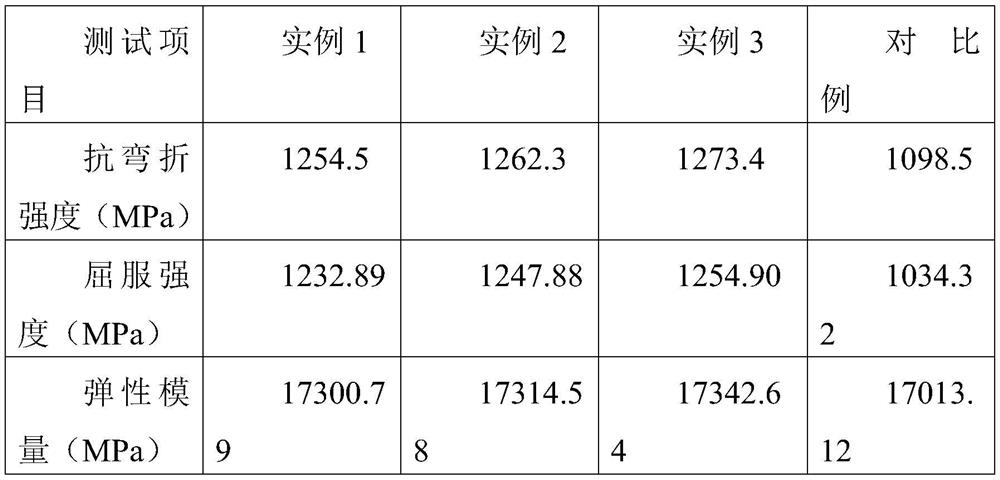

Examples

example 1

[0033]The rice husk and deionized water are mixed according to the mass ratio of 1:7, poured into an ultrasonic cleaner, and ultrasonically cleaned once with a power of 300W. After cleaning, put it into an oven and dry it at 105°C to obtain pretreated rice. Hull: Put the above pretreated rice husks into a carbonization furnace, heat up to 300°C for 10 minutes under the protection of carbon dioxide, then heat up to 1900°C, heat-preserve and carbonize for 9 hours, and discharge after carbonization to obtain rice husk-based carbonization Silicon fiber; after mixing the rice husk-based silicon carbide obtained above and a sodium silicate solution with a mass fraction of 30% in a mass ratio of 1:10, adjust the pH to 5 with hydrochloric acid, continue to stir for 1 hour and filter to obtain a filter residue, and Put the filter residue in a high-temperature reaction kettle, react at 150°C for 30 minutes, filter to obtain the reaction filter residue, and obtain the modified silicon car...

example 2

[0035] The rice husk and deionized water are mixed according to the mass ratio of 1:7, poured into an ultrasonic cleaner, and ultrasonically cleaned twice with a power of 350W. After cleaning, put it into an oven and dry it at 108°C to obtain pretreated rice Hull: Put the above pretreated rice husks into a carbonization furnace, heat up to 330°C for 15 minutes under the protection of carbon dioxide, then heat up to 1950°C, heat-preserve and carbonize for 9 hours, and discharge after carbonization to obtain rice husk-based carbonization Silicon fiber; after mixing the rice husk-based silicon carbide obtained above and a sodium silicate solution with a mass fraction of 30% in a mass ratio of 1:10, adjust the pH to 6 with hydrochloric acid, continue to stir for 2 hours, and filter to obtain a filter residue, and Put the filter residue into a high-temperature reaction kettle, react at 180°C for 35 minutes, filter to obtain the reaction filter residue, and obtain the modified silico...

example 3

[0037] The rice husk and deionized water were mixed according to the mass ratio of 1:7, poured into an ultrasonic cleaner, and ultrasonically cleaned for 3 times with a power of 400W. Hull: Put the above pretreated rice husks into a carbonization furnace, heat up to 350°C for 20 minutes under the protection of carbon dioxide, then heat up to 2000°C, heat-preserve and carbonize for 10 hours, and discharge the material after carbonization to obtain rice husk-based carbonization Silicon fiber; after mixing the rice husk-based silicon carbide obtained above and a sodium silicate solution with a mass fraction of 30% in a mass ratio of 1:10, adjust the pH to 6 with hydrochloric acid, continue to stir for 2 hours, and filter to obtain a filter residue, and Put the filter residue into a high-temperature reaction kettle, react at 200°C for 40 minutes, filter to obtain the reaction filter residue, and obtain the modified silicon carbide fiber; in parts by weight, heat the resistance furn...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com