Medium carbon ferromanganese medium-thick steel for 800MPa engineering machinery and manufacturing method of medium carbon ferromanganese medium-thick steel

A technology of construction machinery and manufacturing methods, applied in the field of iron and steel smelting, to achieve the effects of good hardenability, improved ductility and plasticity, and high strength-yield-tensile ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

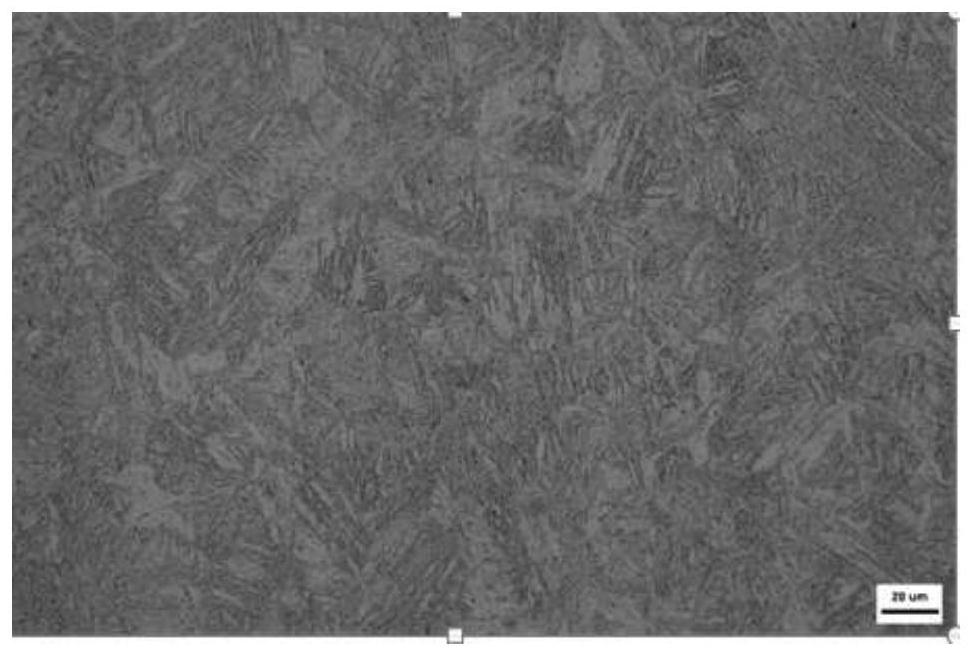

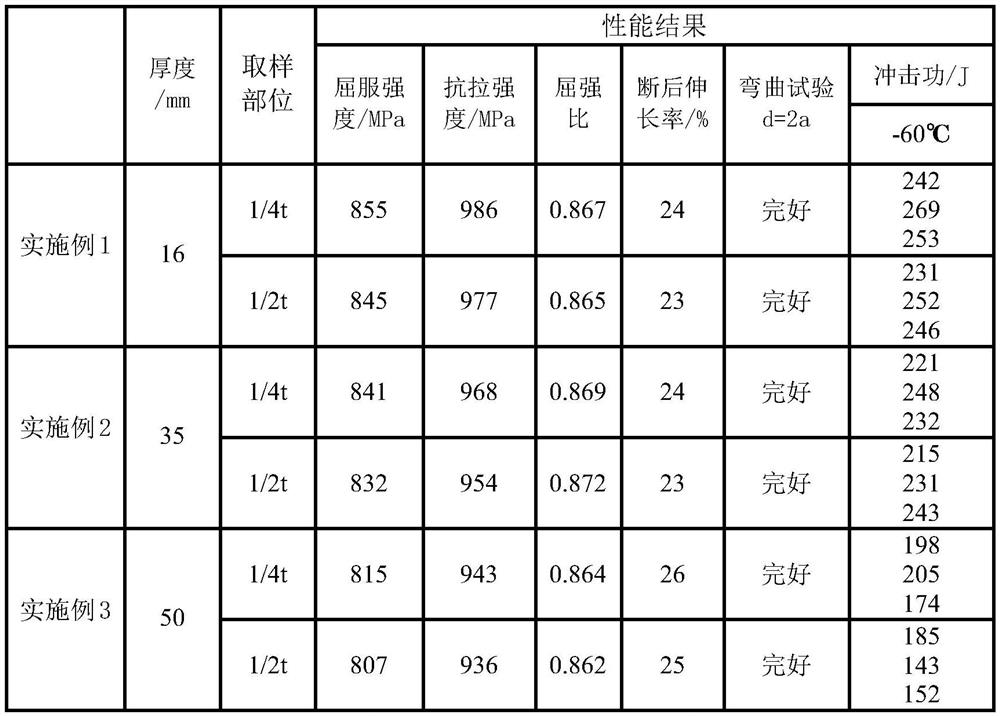

Embodiment 1

[0035] A kind of 800MPa medium-manganese medium-thick steel for engineering machinery provided in this embodiment has a thickness of 16mm, and its chemical composition and mass percentage are as follows: C: 0.06%, Mn: 5.1%, Si: 0.26%, P: 0.007%, S : 0.001%, Ti: 0.035%, Ni+Cr+Mo: 0.92%, and the balance is Fe and unavoidable impurities.

[0036] The manufacturing method is as follows: after the molten iron is desulfurized, it enters the converter for smelting to reduce the content of P and S in the molten steel, P: 0.007%, S: 0.001%; LF refining completes the alloying of the mass fraction of each element, and the casting speed is 1.2m / min to obtain a slab with a thickness of 320mm, and the surface defects should be cleaned up; the slab is heated to a temperature of 1160°C, and the soaking time is 48min; the heated slab is subjected to controlled rolling, the first-stage rolling temperature is 1030°C, and the final rolling The temperature is 945°C, the second-stage rolling tem...

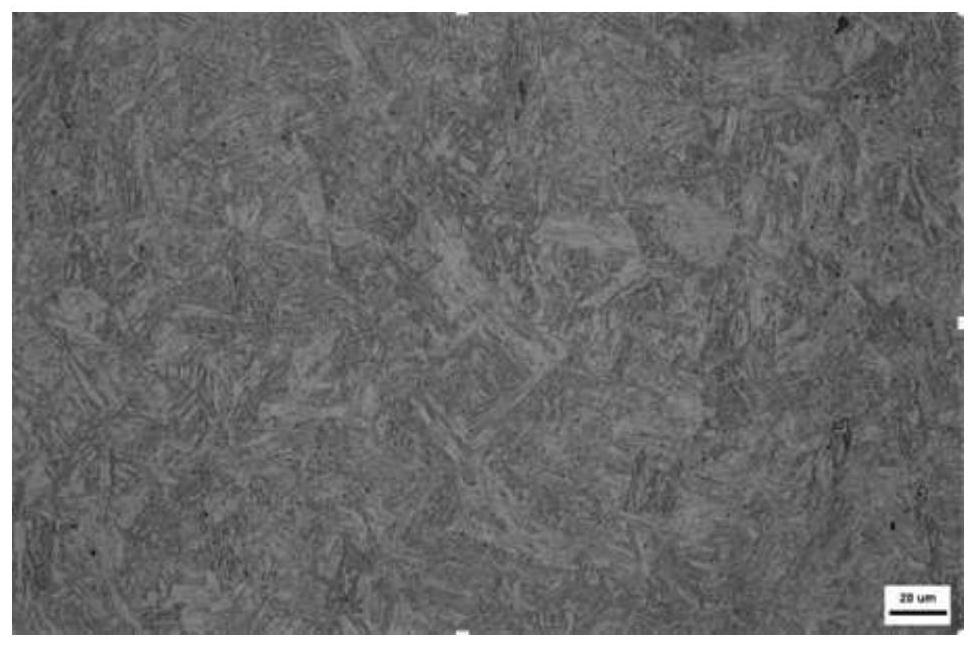

Embodiment 2

[0038] A kind of 800MPa medium-manganese medium-thick steel for construction machinery provided in this embodiment has a thickness of 35mm, and its chemical composition and mass percentage are as follows: C: 0.065%, Mn: 5.3%, Si: 0.26%, P: 0.007%, S : 0.001%, Ti: 0.021%, Ni+Cr+Mo: 1.13%, and the balance is Fe and unavoidable impurities.

[0039]The manufacturing method is as follows: after the molten iron is desulfurized, it enters the converter for smelting to reduce the content of P and S in the molten steel, P: 0.007%, S: 0.001%; LF refining completes the alloying of the mass fraction of each element, and the casting speed is 1.2m / min to obtain a slab with a thickness of 320mm, and the surface defects should be cleaned up; the slab is heated to a temperature of 1150°C, and the soaking time is 48min; the heated slab is subjected to controlled rolling, the first-stage rolling temperature is 1030°C, and the final rolling The temperature is 940°C, the second-stage rolling te...

Embodiment 3

[0041] A kind of 800MPa medium-manganese medium-thick steel for engineering machinery provided in this embodiment has a thickness of 50mm, and its chemical composition and mass percentage are as follows: C: 0.075%, Mn: 5.5%, Si: 0.23%, P: 0.007%, S : 0.001%, Ti: 0.021%, Ni+Cr+Mo: 1.15%, and the balance is Fe and unavoidable impurities.

[0042] The manufacturing method is as follows: after the molten iron is desulfurized, it enters the converter for smelting to reduce the content of P and S in the molten steel, P: 0.007%, S: 0.001%; LF refining completes the alloying of the mass fraction of each element, and the casting speed is 1.2m / min to obtain a slab with a thickness of 320mm, and the surface defects should be cleaned up; the slab is heated to a temperature of 1125°C, and the soaking time is 55min; the heated slab is subjected to controlled rolling, the first-stage rolling temperature is 1025°C, and the final rolling The temperature is 945°C, the second-stage rolling te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com