A method for preparing needle coke by using three-stage tandem refining raw materials

A three-stage series, needle coke technology, applied in coke ovens, coking carbonaceous materials, petroleum industry and other directions, can solve the problems of incomplete removal of oxygen elements, high cost of coal tar raw material modification methods, and achieve low cost, The effect of good uniformity and simple modification process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

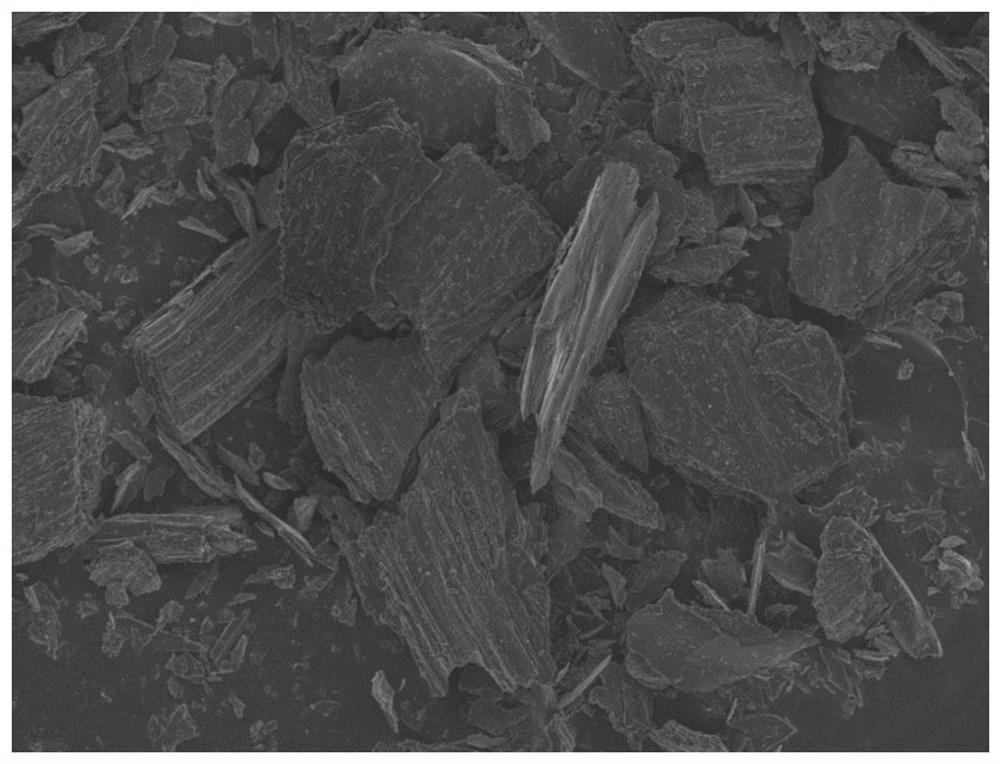

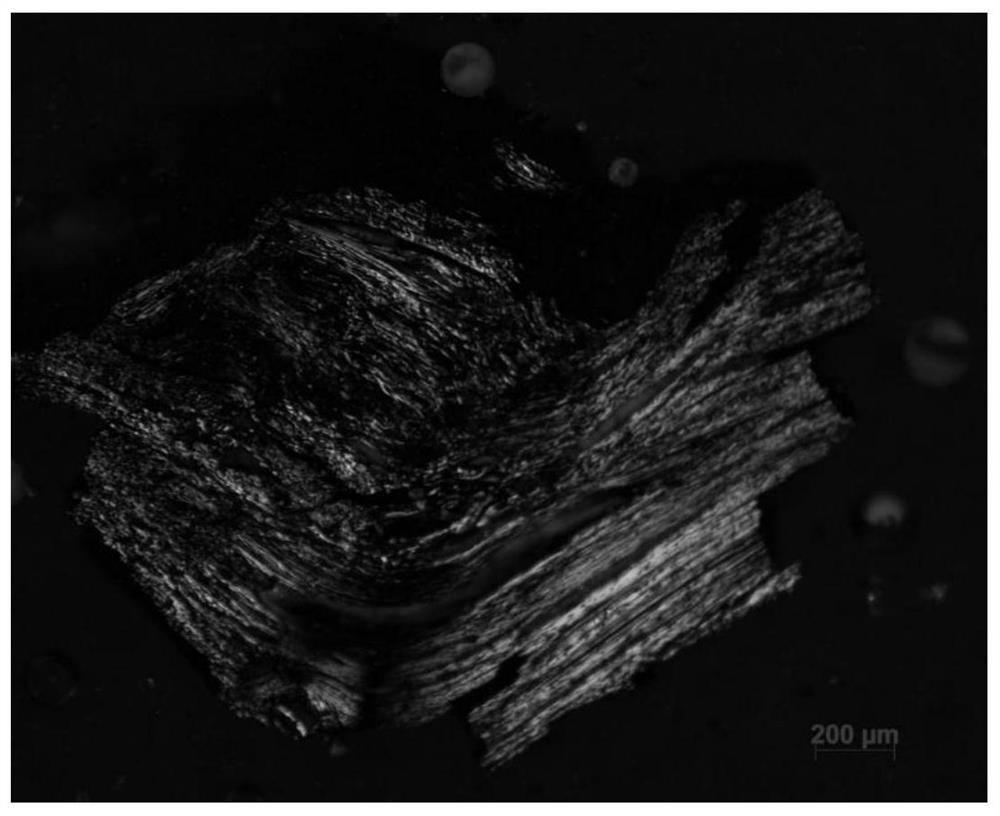

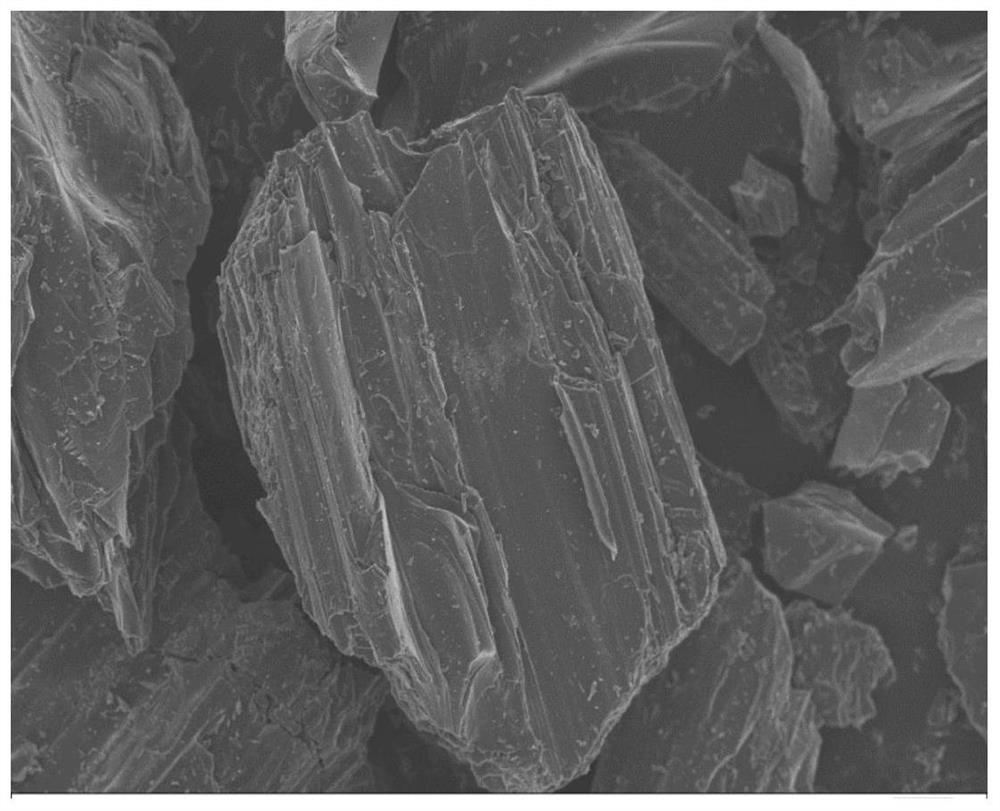

Image

Examples

Embodiment 1

[0046]A method for preparing needle coke with three-stage series-connected refining raw materials according to the present embodiment, the steps are:

[0047] Take 2.5kg of medium and low temperature coal tar and put it in the rectification reactor for fraction cutting, and cut out the pitch of 300-400 ℃ fraction, its softening point is 60 ℃, the aromaticity is f A is 0.7; take 150 g of the cut asphalt, transfer it into an autoclave, and under the air flow rate of 15 L / h, raise the temperature to 160 ℃ at a heating rate of 3 ℃ / min and keep it for 3 hours to prepare modified asphalt; give Nitrogen was continuously introduced into the autoclave for 8 minutes to replace the air in the autoclave; in the sand bath environment, 100g of modified asphalt and 10g of modifier were mixed and placed in the autoclave, maintaining a pressure of 1Mpa, At a stirring rate of 100r / min, the temperature was raised to 110°C at a heating rate of 4°C / min, and the phenolic resin macromolecules in the...

Embodiment 2

[0052] A method for preparing needle coke with three-stage series-connected refining raw materials according to the present embodiment, the steps are:

[0053] Take 2.5kg of medium and low temperature coal tar and put it in the rectification reactor for fraction cutting, and cut out the pitch of 300-400 ℃ fraction, its softening point is 60 ℃, the aromaticity is f A is 0.7; take 150g of the cut asphalt, transfer it into an autoclave, and under the air flow rate of 15L / h, heat it up to 130°C at a heating rate of 3°C / min and keep it for 3 hours to prepare modified asphalt; give Nitrogen was continuously introduced into the autoclave for 8 minutes to replace the air in the autoclave; in the sand bath environment, 100g of modified asphalt and 10g of modifier were mixed and placed in the autoclave, maintaining a pressure of 1Mpa, At a stirring rate of 100r / min, the temperature was raised to 110°C at a heating rate of 4°C / min, and the phenolic resin macromolecules in the modified as...

Embodiment 3

[0058] A method for preparing needle coke with three-stage series-connected refining raw materials according to the present embodiment, the steps are:

[0059] Take 2.5kg of medium and low temperature coal tar and put it in the rectification reactor for fraction cutting, and cut out the pitch of 300-400 ℃ fraction, its softening point is 60 ℃, the aromaticity is f A is 0.7; take 150g of the cut asphalt, transfer it into the autoclave, under the oxygen flow rate of 10L / h, heat up to 110 ℃ at a heating rate of 3 ℃ / min, hold for 3 hours, prepare modified asphalt; give Inert gas was continuously fed into the autoclave for 8 minutes to replace the oxygen in the autoclave; in the sand bath environment, 100g of modified asphalt and 10g of modifier were mixed and placed in the autoclave to maintain a pressure of 1Mpa , 100r / min stirring speed, heat up to 110°C at a heating rate of 4°C / min, discharge the macromolecular intolerant of phenolic resin in the modified asphalt from the botto...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com