Strengthening method of base assembly welding sequence

A group welding and sequential technology, which is applied in welding equipment, earthwork drilling, manufacturing tools, etc., can solve the problems that the column socket cannot be covered, the source of weld cracking, and the load-bearing area can be reduced, so as to improve and optimize the welding process parameters , Improve the welding process sequence, improve the effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0023] The base group welding order of the present invention is enhanced, and the preferred embodiment is:

[0024] The base assembly includes a top plate, a pad, a cover plate, a rib, a rubber, a bending plate, a main guide, a column nest, a bridge, an overall assembly, and a welding order comprises:

[0025] One welding:

[0026] First, assemble the main tene and the top plate and weld the weld;

[0027] Then, the side of the bridge and the left side of the bridge and the left side of the bridging plate are welded, and the remaining unbained weld is only soldered, and the same column nest is continuously welded;

[0028] Secondary welding: set the pads and weld the pad;

[0029] Talking three times: The cover is good, and the cover solder is welded by the pillar nest, and the remaining unbained weld is only soldered, and the same column nest is continuously welded;

[0030] Four welding:

[0031] First, the column, the ribs are combined, and the ribs and the hoe-shaped pillars a...

specific Embodiment

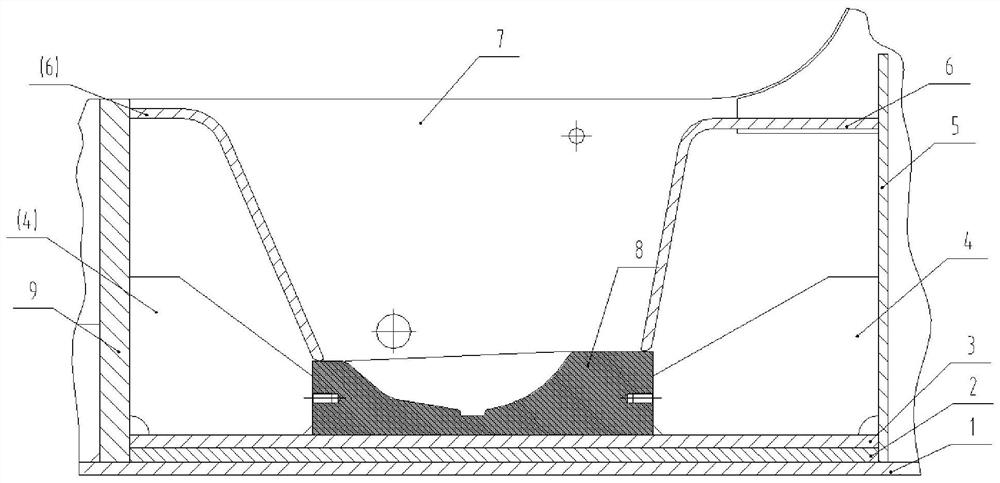

[0037] Overall assembly, welding order:

[0038] Such as figure 1 Distance

[0039] Once, 1 first, the outer exterior tendons are assembled and welded to weld;

[0040] 2 is covered by the pad and the left side of the bridge and the left end of the bond plate and the upper left end of the support is welded. The remaining unbelled weld is only soldered, and the same column nest is continuously welded.

[0041] Second, 1 pad group is good and welded.

[0042] Three times, 1 cover group, and will weld the cover solder by the pillar nest, and the remaining unbained weld is only soldered, and the same column nest is continuously welded.

[0043] Four times, 1 pillar, the ribs, the ribs and bending plates are welded;

[0044] 2 Remaining bridge right end weld, remaining cover weld, left ends of the remaining support.

[0045] Five times, 1 bending plate group is good, the bending plate weld and the remaining welds of the pillarside are welded.

[0046] The present invention has the adva...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com