Control method for direct current motor load at starting moment

A control method and technology for DC motors, which are applied to the starter of a single DC motor, the deceleration device of an AC motor, a motor generator/starter, etc. problem, to achieve the effect of good adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

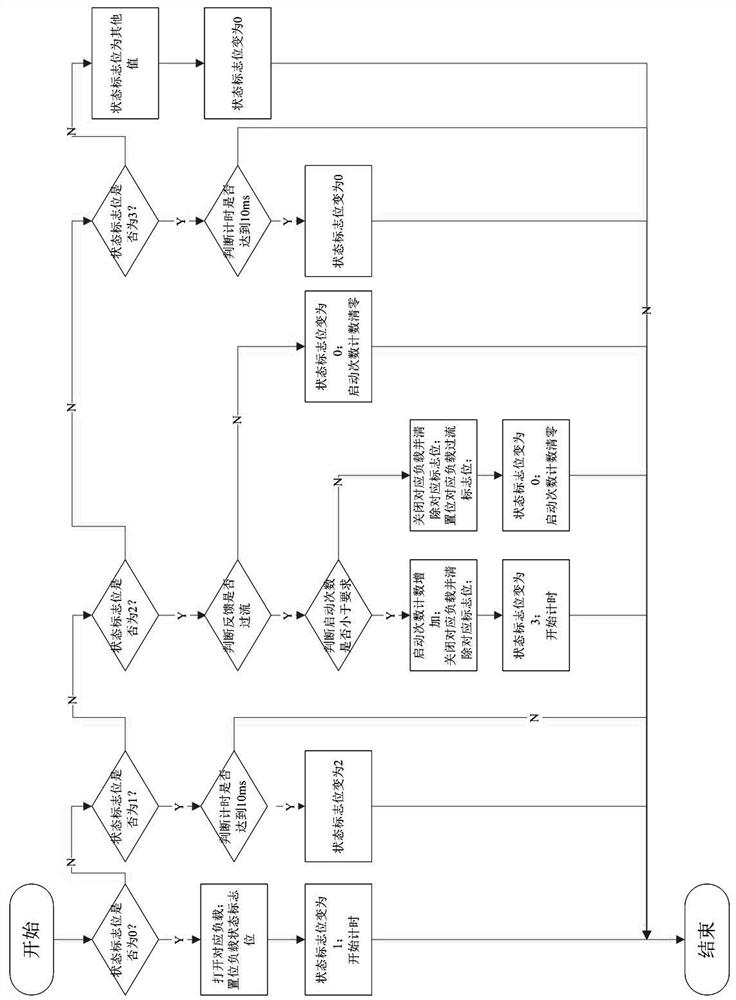

[0023] This embodiment is a method for controlling a DC motor load at the moment of starting, comprising the following steps:

[0024] (1) The MCU sends a conduction control signal to control the conduction of the motor load, the motor rotates, and the current increases;

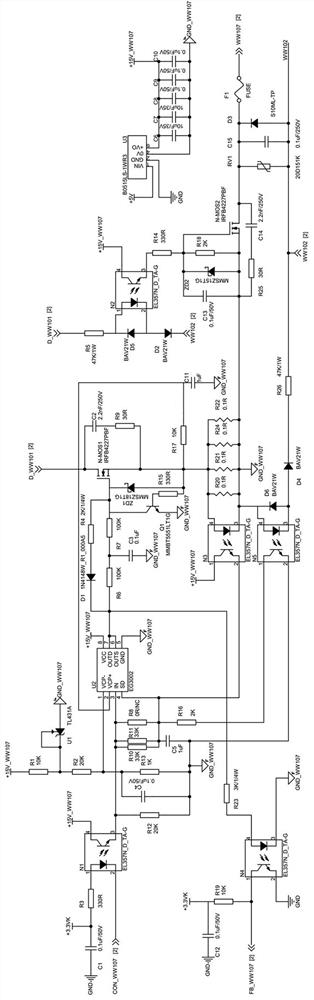

[0025] (2) The hardware circuit detects that the current is too high, the hardware circuit cuts off the motor load power supply and feeds back the overcurrent signal to the MCU microcontroller, the motor keeps rotating due to inertia but the speed drops rapidly;

[0026] (3) After the MCU microcontroller reads the overcurrent signal, it disconnects the conduction control signal. After a short delay, the MCU microcontroller sends the conduction control signal again to control the motor load to conduct, and the motor continues to rotate;

[0027] (4) Repeat steps (2) and (3) until th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com