Prefabricated concrete frame and assembling method

A prefabricated assembly and concrete technology, which is applied to building components, building insulation materials, fire protection, etc., can solve problems such as dumping, time-consuming and labor-intensive efficiency, and tilting of the center of gravity of concrete frames, so as to improve safety and ensure stable connections.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

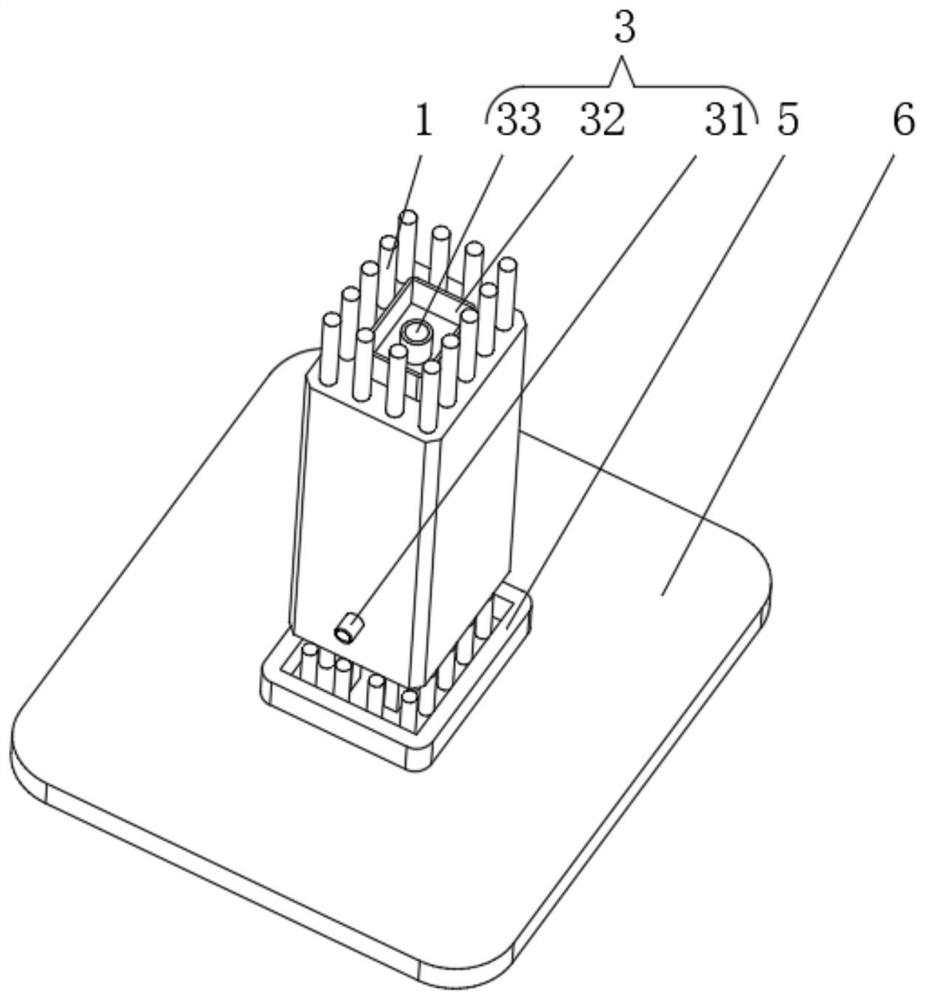

[0031] The prefabricated concrete frame and assembly method, such as Figure 1-5 As shown, it includes: an installation block 6, a frame member 2 and a positioning device 4, the frame member 2 is located directly above the installation block 6, the lower surface of the frame member 2 is provided with a grouting groove 8, and the upper surface of the installation block 6 is provided with a positioning device 4.

[0032] The specific setting and effect of its positioning device 4 and pouring device 3 are introduced in detail below.

[0033] Such as figure 1 and Figure 5 As shown, the positioning device 4 includes a positioning rod 41, the positioning rod 41 is fixedly connected to the upper surface of the mounting block 6, the lower surface of the frame member 2 is provided with a positioning groove 45, the positioning rod 41 is inserted into the positioning groove 45 and abuts against its inner wall, the frame The upper surface of the component 2 is fixedly connected with t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com