Diatom health board and preparation method thereof

A healthy and diatom mud technology, applied in the field of building materials, can solve problems such as environmental protection, impact, and limited applicable space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

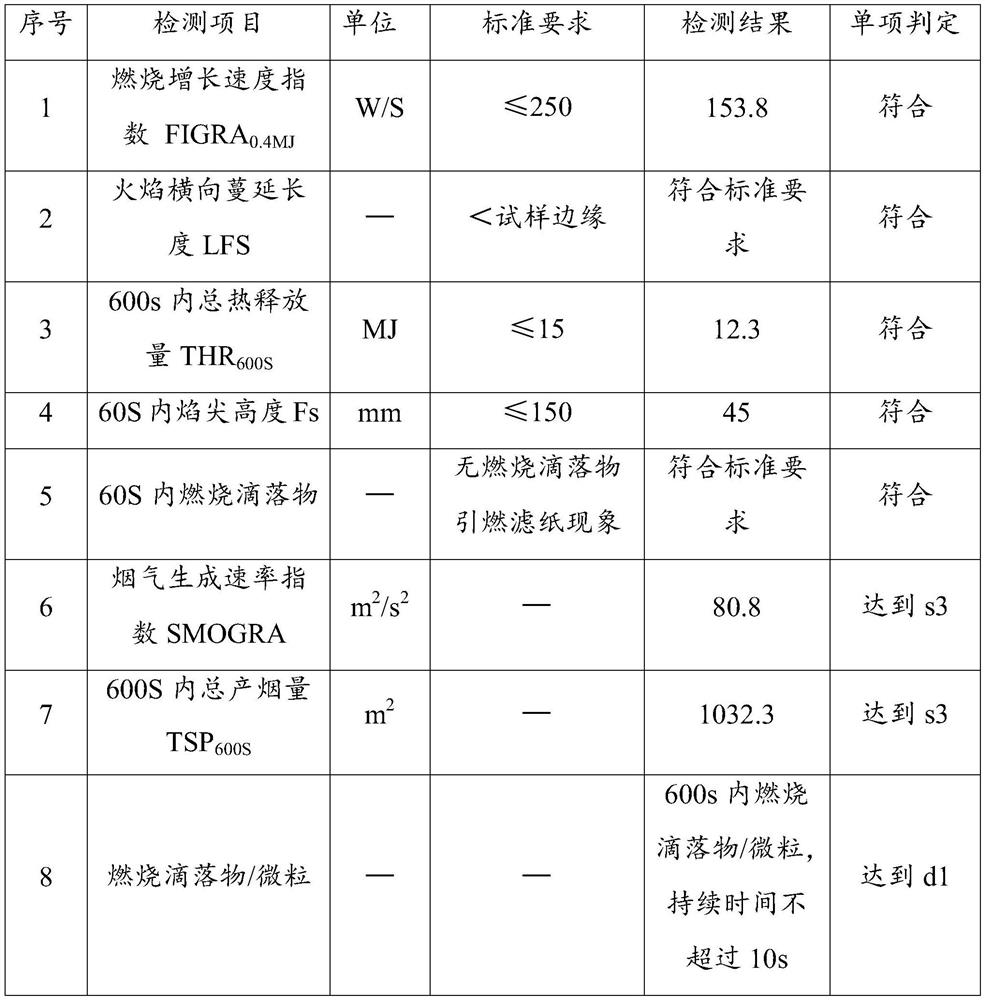

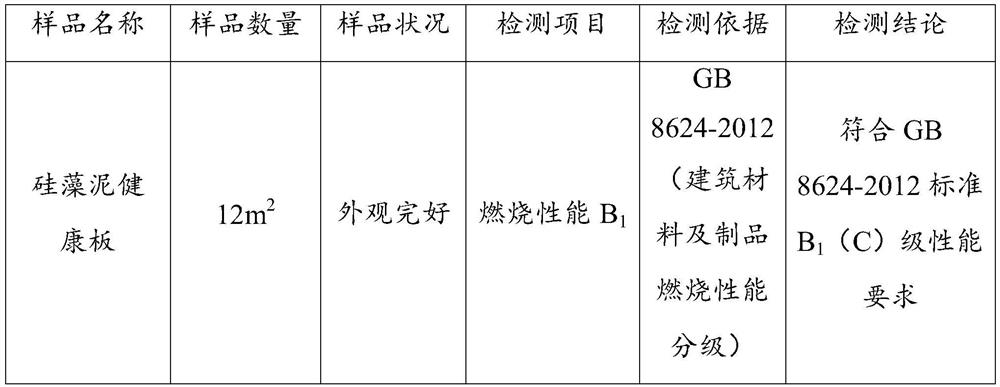

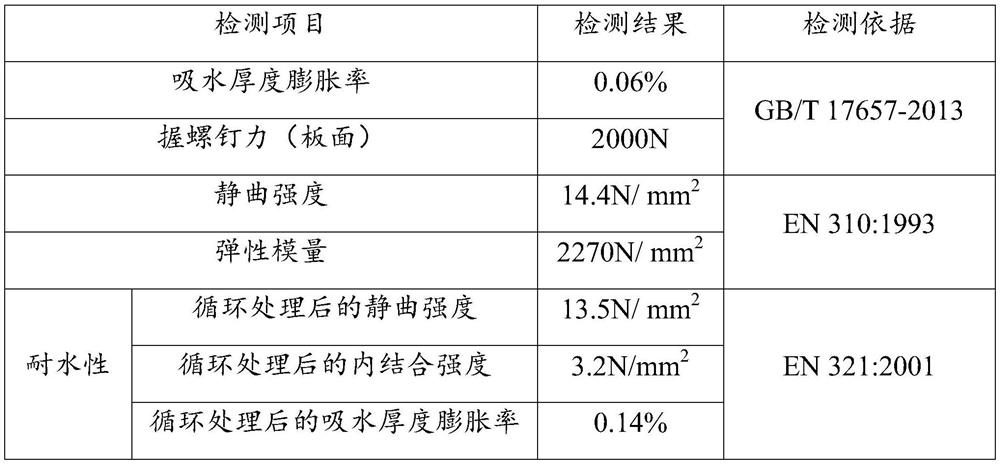

Examples

Embodiment 1

[0035] A diatom ooze health board comprises the following raw materials in parts by weight:

[0036] 20 parts of diatomite, 5 parts of negative oxygen ion powder, 20 parts of polyvinyl chloride, 40 parts of calcium titanate, 2 parts of plant fiber, 0.05 part of water-based color paste, 0.5 part of preservative.

[0037] A silica gel mud health board, the diatomite, negative oxygen ion powder and calcium titanate are 300 mesh.

[0038] A kind of preparation method of diatom ooze healthy plate, comprises the steps:

[0039] (1) Mix the above-mentioned raw materials according to the proportion, and then put the mixed material into the mixer and stir evenly for 30 minutes;

[0040] (2) After uniform stirring and complete fusion, put the uniformly stirred raw materials into a heating furnace for heating and mixing. The heating temperature of the heating furnace is controlled at 800° C., and the heating time is 2 hours.

[0041] (3) Put the heated and mixed raw materials into a co...

Embodiment 2

[0047] A diatom ooze health board comprises the following raw materials in parts by weight:

[0048] 30 parts of diatomite, 8 parts of negative oxygen ion powder, 35 parts of polyvinyl chloride, 50 parts of calcium titanate, 4 parts of plant fiber, 0.25 parts of water-based color paste, and 0.7 parts of preservative.

[0049] A silica gel mud health board, the diatomaceous earth, negative oxygen ion powder and calcium titanate are 400 mesh.

[0050] A kind of preparation method of diatom ooze healthy plate, comprises the steps:

[0051] (1) Mix the above-mentioned raw materials according to the proportion, and then put the mixed material into the mixer and stir evenly for 30 minutes;

[0052] (2) After uniform stirring and complete fusion, put the uniformly stirred raw materials into a heating furnace for heating and mixing. The heating temperature of the heating furnace is controlled at 1100° C., and the heating time is 1.5 hours.

[0053] (3) Put the heated and mixed raw m...

Embodiment 3

[0059] A diatom ooze health board comprises the following raw materials in parts by weight:

[0060] 40 parts of diatomite, 10 parts of negative oxygen ion powder, 50 parts of polyvinyl chloride, 60 parts of calcium titanate, 5 parts of plant fiber, 0.5 parts of water-based color paste, 1 part of preservative.

[0061] A silica gel mud health board, the diatomite, negative oxygen ion powder and calcium titanate are 500 mesh.

[0062] A kind of preparation method of diatom ooze healthy plate, comprises the steps:

[0063] (1) Mix the above-mentioned raw materials according to the proportion, and then put the mixed material into the mixer and stir evenly for 30 minutes;

[0064](2) After uniform stirring and complete fusion, put the uniformly stirred raw materials into a heating furnace for heating and mixing. The heating temperature of the heating furnace is controlled at 1500° C., and the heating time is 1 h.

[0065] (3) Put the heated and mixed raw materials into a cold po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com