Building rubbish recovering treatment device

A technology for recycling and processing construction waste, which is applied in construction waste recycling, grain processing, recycling technology, etc., can solve the environment of flying dust and sand, does not have recycling and reuse, consumes large land acquisition fees, garbage removal and transportation costs, and construction funds and other issues to achieve the effect of reducing pollution and saving construction raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

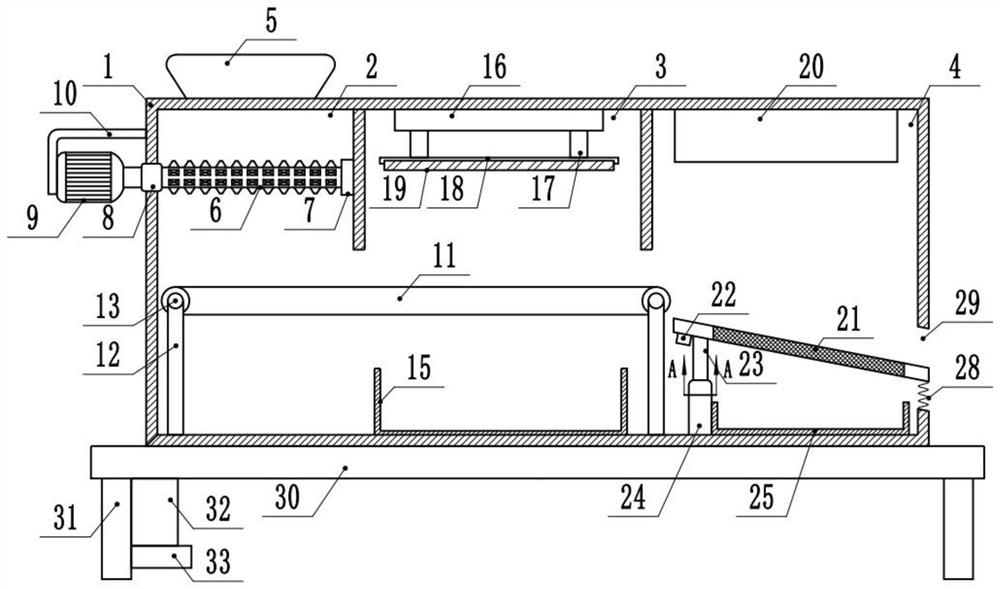

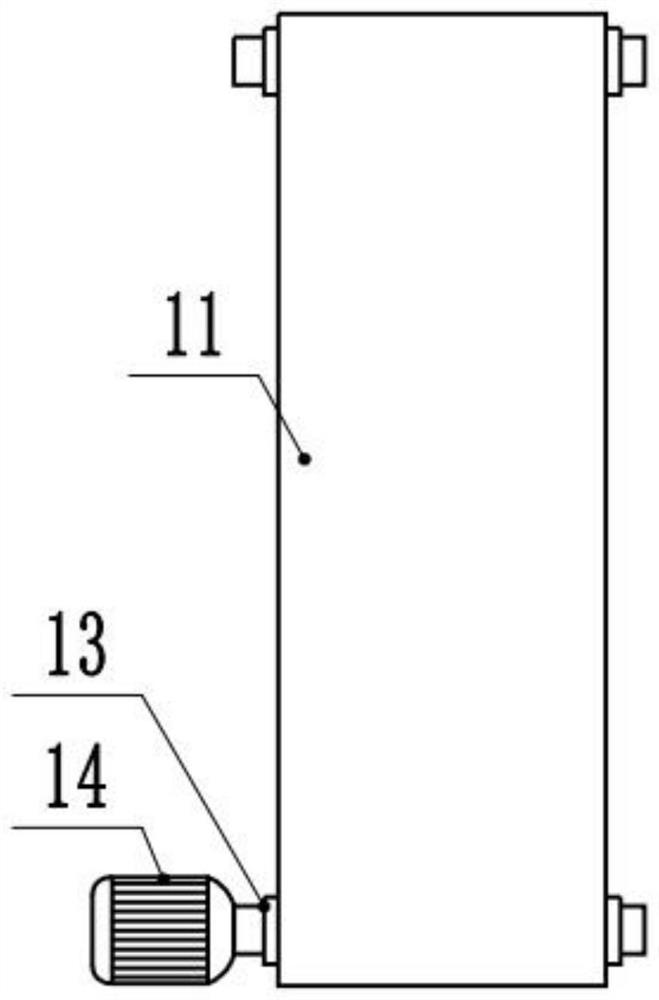

[0024] see Figure 1-5 , a construction waste recovery treatment device, a construction waste recovery treatment device, including a device box 1, the inside of the device box 1 is sequentially provided with a crushing chamber 2, a first recovery chamber 3 and a second recovery chamber 4 from left to right.

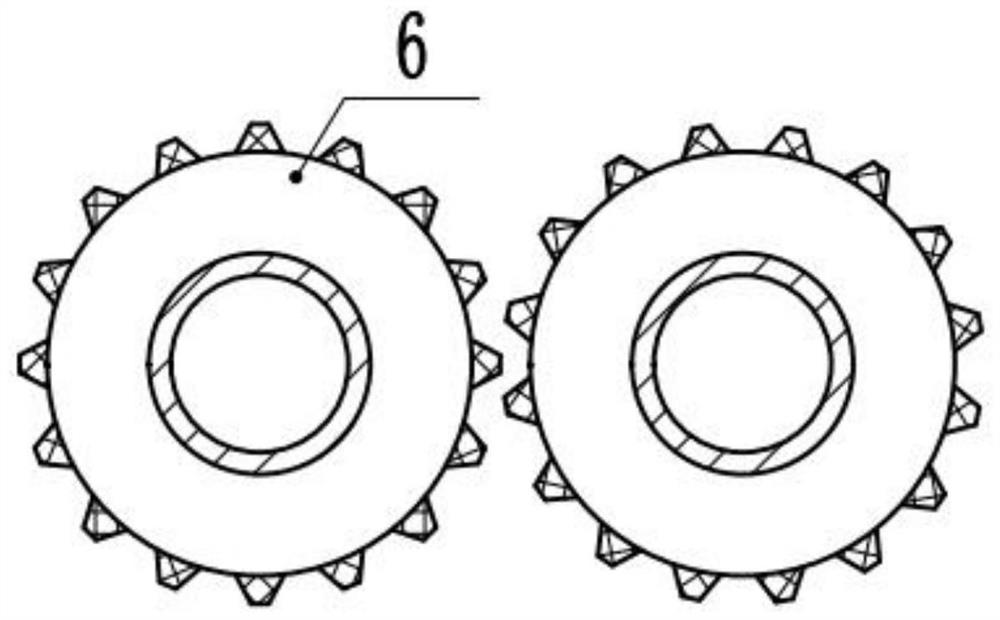

[0025] In addition, a shaft sleeve 7 is fixedly connected to the top of the inner wall on the right side of the crushing chamber 2, and a crushing roller 6 is installed on the other side of the shaft sleeve 7 for rotation. connected, and the other end of the crushing roller 6 is rotated with a crushing motor 9, the crushing motor 9 is fixedly connected with the outer wall of the crushing chamber 2 through the motor frame 10, and the upper part of the first recovery chamber 3 is fixedly connected with a fixed block 16, the fixed block 16 left and right Both sides are provided with chute 34 inside, and electric sliding cylinder 17 is slidably installed in chute 34, and conn...

Embodiment 2

[0028] see Figure 1-5 , a construction waste recovery treatment device, a construction waste recovery treatment device, including a device box 1, the inside of the device box 1 is sequentially provided with a crushing chamber 2, a first recovery chamber 3 and a second recovery chamber 4 from left to right.

[0029] In addition, a shaft sleeve 7 is fixedly connected to the top of the inner wall on the right side of the crushing chamber 2, and a crushing roller 6 is installed on the other side of the shaft sleeve 7 for rotation. connected, and the other end of the crushing roller 6 is rotated with a crushing motor 9, the crushing motor 9 is fixedly connected with the outer wall of the crushing chamber 2 through the motor frame 10, and the upper part of the first recovery chamber 3 is fixedly connected with a fixed block 16, the fixed block 16 left and right Both sides are provided with chute 34 inside, and electric sliding cylinder 17 is slidably installed in chute 34, and conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com