An axial flux motor stator

A technology of motor stator and axial magnetic flux, which is applied to magnetic circuits, electromechanical devices, electrical components, etc., can solve the problems of increased stator loss, decreased motor torque output capability, large air gap, etc., and achieves high core utilization. , The effect of reducing processing difficulty and increasing process difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings.

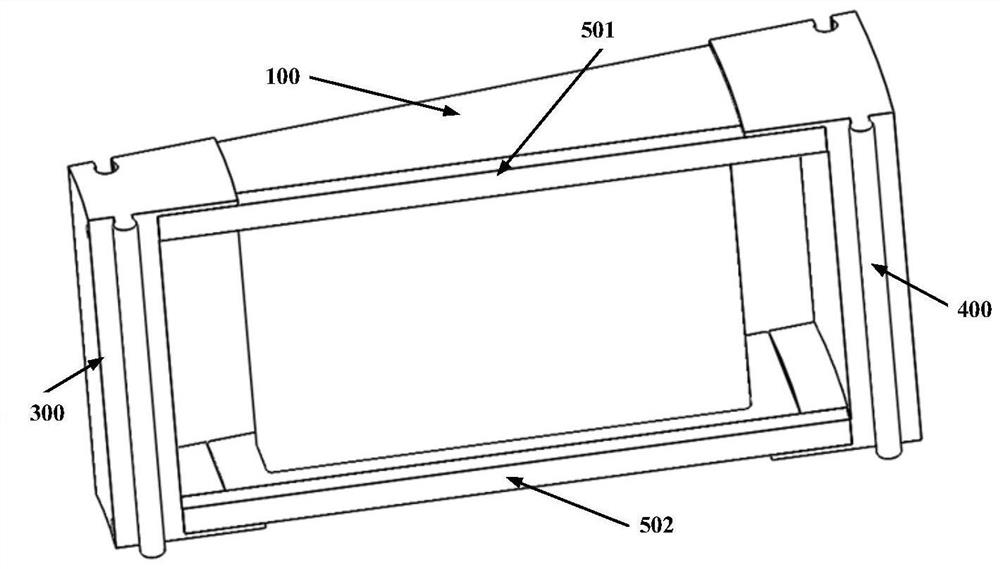

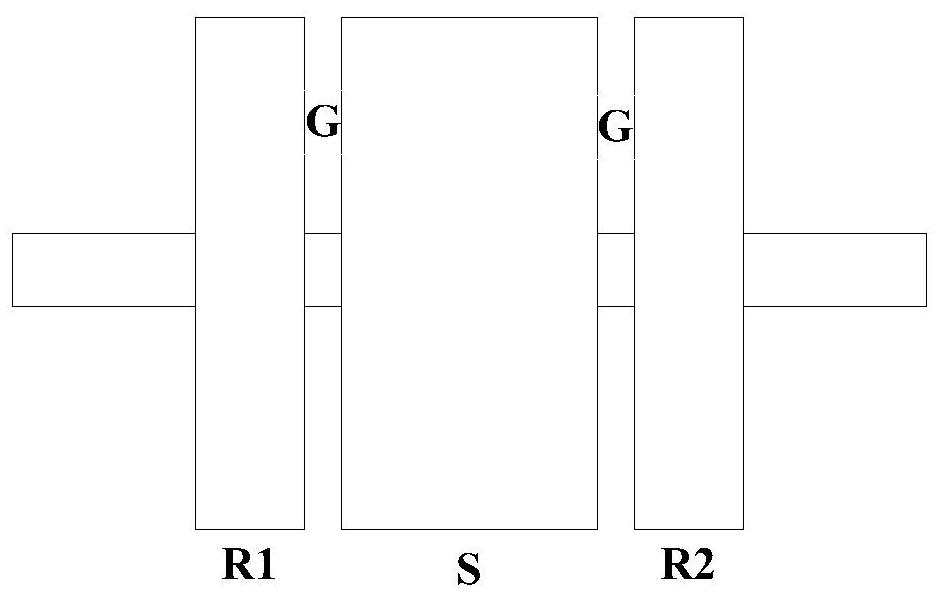

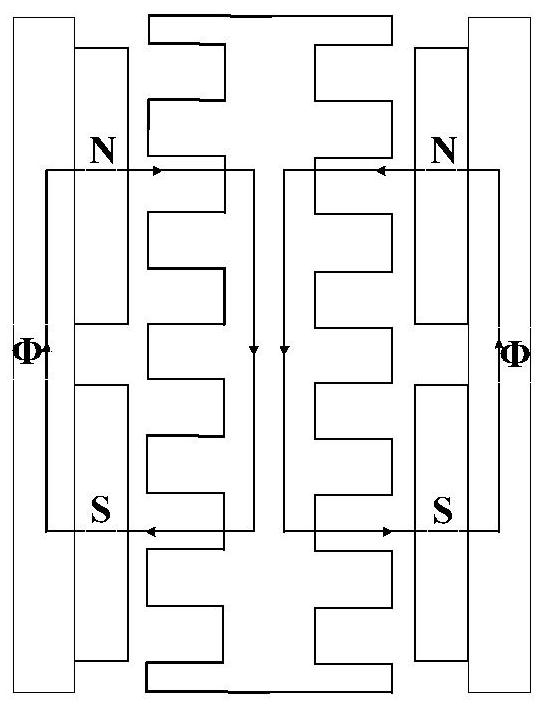

[0049] The present invention proposes an axial flux motor stator comprising a plurality of segmented cores such as figure 2 and 5 As shown, each segmented iron core includes a laminated iron core 200 and an SMC soft magnetic sleeve 100, the SMC soft magnetic sleeve 100 includes a No. 1 SMC soft magnetic sleeve 101 and a No. 2 SMC soft magnetic sleeve 102, and the No. 1 SMC soft magnetic sleeve 101 and The structure of No. 2 SMC soft magnetic sleeve 102 is the same. No. 1 SMC soft magnetic sleeve 101 and No. 2 SMC soft magnetic sleeve 102 are spliced and coated on the outer circumference of laminated iron core 200, and the coil is directly wound on the outer circumference of SMC soft magnetic sleeve 100. .

[0050] In this embodiment, the SMC soft magnetic sleeve can wrap the entire exterior of the laminated iron core 200, and the lamin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com