A gas distribution device and a gas water heater using the same

A technology for gas water heaters and distribution devices, which is applied to gas fuel burners, gaseous fuel supply/distribution, burners, etc., and can solve problems such as failure of gas flow regulation, fewer stages, and lower thermal efficiency of unilateral combustion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

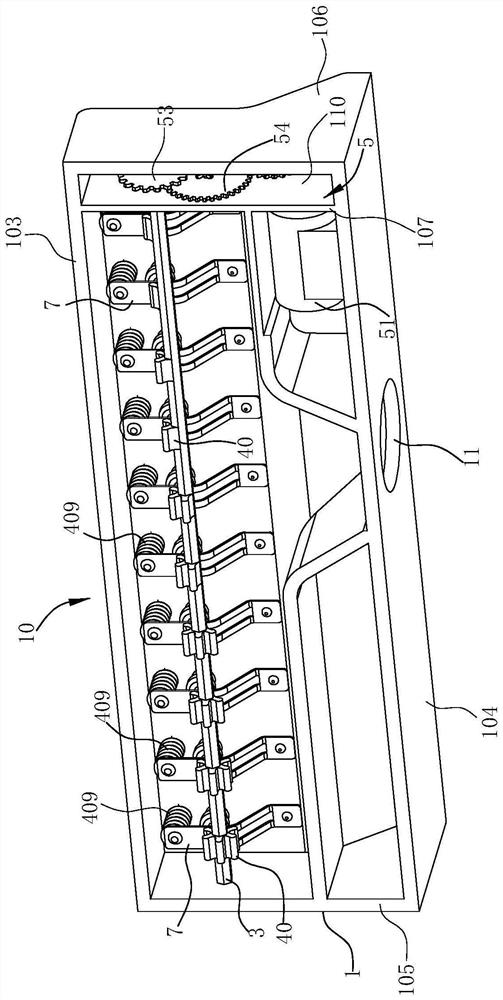

[0044] Such as Figure 7 As shown, the gas distribution device 10 of this preferred embodiment can be used in a gas water heater, and of course it can also be used in a gas wall-hung boiler. The gas water heater includes a burner 101, a gas distribution device 10 and a gas valve group 102 for controlling the gas intake.

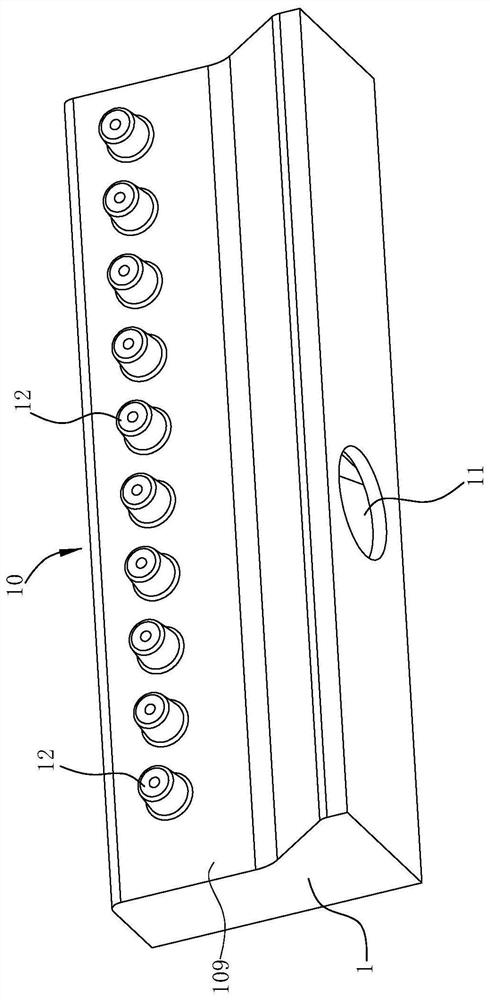

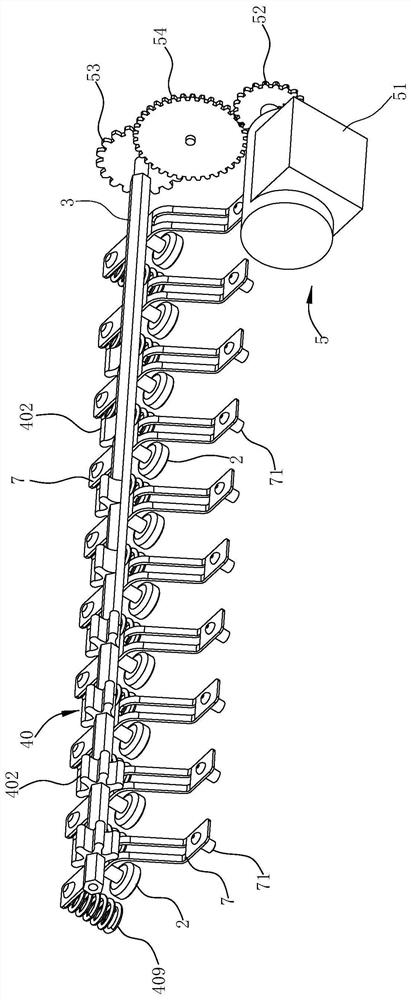

[0045] Such as Figure 1~6 As shown, the gas distribution device 10 includes a housing 1, a nozzle 12, a blocking member 2, a rotating shaft 3, a driving block group 40, a power mechanism 5 and a seesaw 7, the blocking member 2, a rotating shaft 3, a driving block group 40 and a power The mechanism 5 forms a plugging mechanism for plugging the nozzle 12 . Housing 1 comprises top plate 103, bottom plate 104, left side plate 105, right side plate 106, connecting plate 107, front side plate 108 and rear side plate 109, top plate 103, bottom plate 104, left side plate 105, right side plate 106 and The rear side plate 109 is integrally formed in the shape of a b...

Embodiment 2

[0061] The difference between Embodiment 2 and Embodiment 1 lies in that the driving block group 40 and its driving block 402 on the rotating shaft 3 are arranged differently.

[0062] Such as Figure 8 As shown, among the driving blocks 402 on the non-adjacent driving block group 40, at least two driving blocks 402 are distributed on the same straight line parallel to the rotating shaft 3, in other words, the driving blocks 402 located on the same straight line are not adjacently arranged. Instead, they are arranged at intervals, so the correspondingly driven blocking parts 2 are not adjacently arranged, so that the opened nozzles 12 are scattered rather than adjacent, so that the combustion flame will not be too concentrated to burn the heat exchanger and affect the life of the whole machine. And at least two groups of driving block groups 40 have the same number of driving blocks 402 but are arranged differently in the circumferential direction of the rotating shaft 3 .

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com