A collaborative mining method that can be mined under pressure

A mining method and ore body technology, applied in the field of collaborative mining method, can solve problems such as occupying a large amount of funds, affecting mine economic benefits, and lagging in reaching production capacity, and achieve the effects of efficient shoveling, reduction of waste rock mixing rate, and short distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to make the purpose and technical solutions of the present invention clearer, the present invention is further described below in conjunction with the accompanying drawings and embodiments:

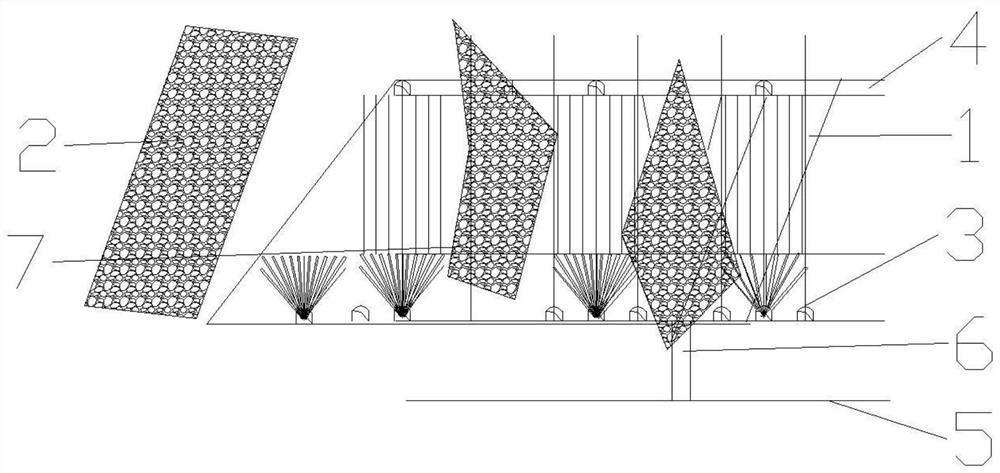

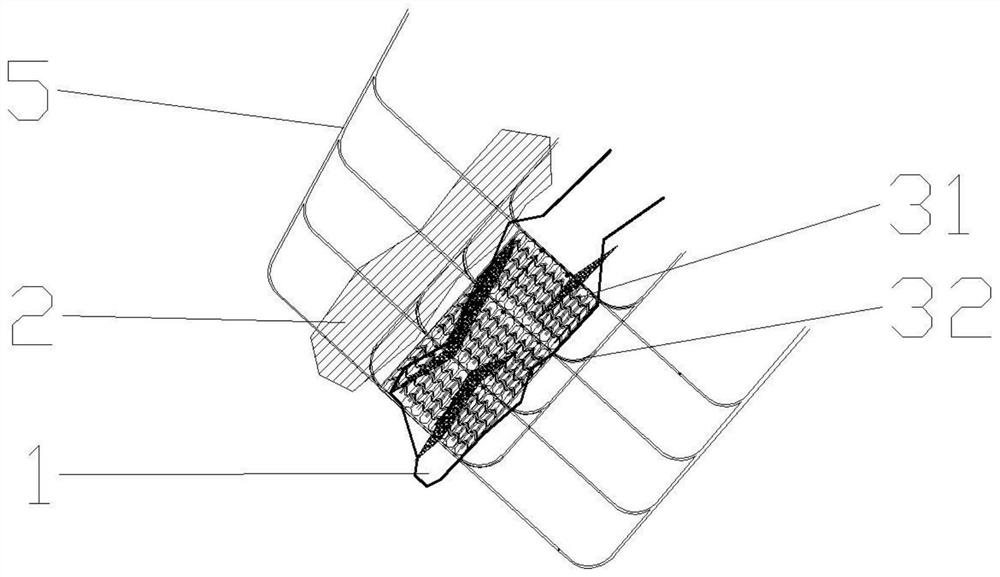

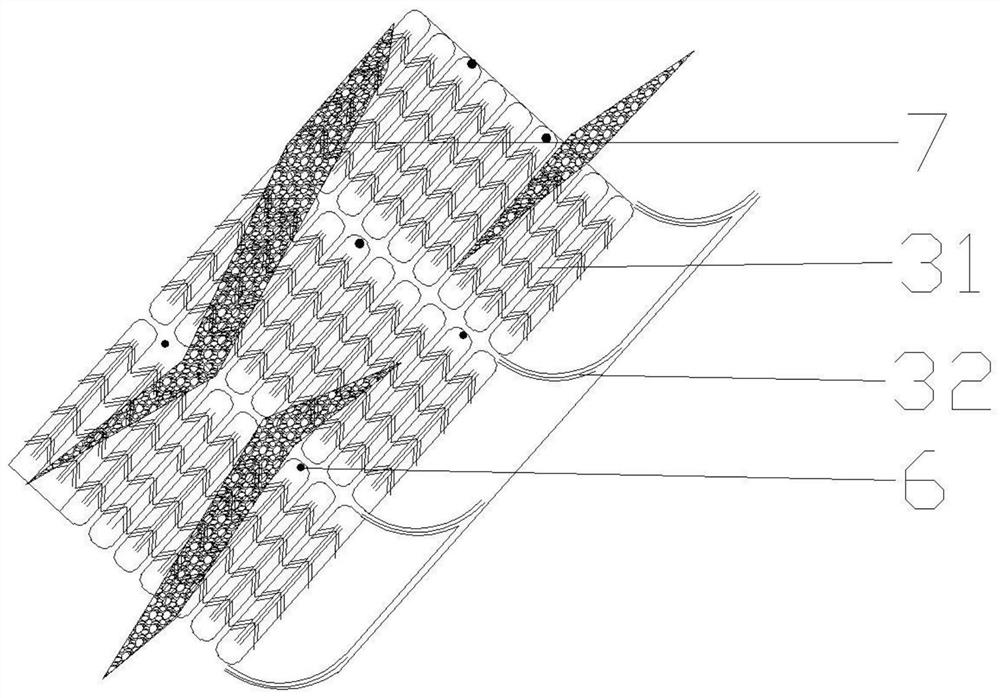

[0022] like Figure 1 to Figure 3 The shown is a collaborative mining method that can be mined under pressure. The rock between the ore body 1 and the water body is used as the water barrier 2, and the ore body adopts the subsequent filling mining method. Drilling holes or large-diameter deep-hole rock drilling, and the bottom structure of the stage is used to mine; the layout of the mining project is: the mine house 31 at the mine outlet level 3 is arranged along the strike, and there is a through-vein roadway 32; above the mine outlet level 3 is the mine. Body 1, the top of the ore body 1 is provided with a rock drilling level and a blasting level 4, and below the ore mining level 3 is provided with a piercing lane 5, and the piercing lane 32 is parallel to the piercing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com