Airbag detonating machine

A technology of airbags and racks, applied in the direction of solid waste removal, etc., can solve the problems of low work efficiency, unfavorable operation of operators, environmental pollution, etc., and achieve the effects of environmental protection, work efficiency improvement, and reasonable structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

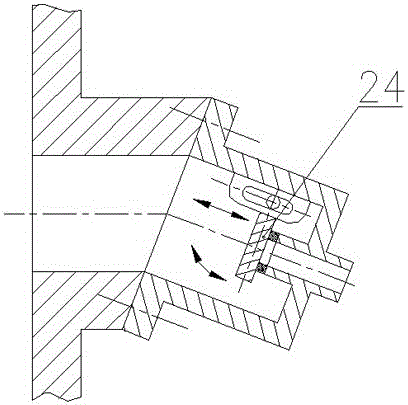

[0023] see Figure 1-Figure 4 , a kind of safety air bag detonating machine that the present invention relates to, it comprises wheel 1, frame 2, storage battery 3, operation control cabinet 4, line retractor 5, push-pull handle 6, video display 7, vacuum cleaner 8, muffler 9, detonation Box 10, gas spring 11, box cover 12, hook head 13, handle 14, wire clamp assembly 15, lifting table 16, lighting 17, camera 18, air inlet 19, electric cylinder 20, lifting switch 21, contact switch 22. Safety hook assembly 23, dodge door 24 and control panel 25.

[0024] The wheels 1 are installed on the bottom of the frame 2; the storage battery 3 is arranged in the operation control cabinet 4; Displays the electronic control system and airbag detonation electronic control system. Wherein vacuum cleaner working electric control system comprises vacuum cleaner switch, vacuum cleaner timer, vacuum cleaner 8, power supply and control circuit, can arbitrarily select vacuuming working time, real...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com